Inverter DC TIG/MMA Welding Machine (IGBT Module type)

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 100 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Basic Info.

Model NO.:TIG/MMA

Type:ARC Welders

Current:AC/DC

Model:TIG/MMA

Export Markets:Global

Additional Info.

Packing:Carton

Standard:ISO9001: 2008, CE, CB, CCC

Origin:China

Production Capacity:100 Pieces/Day

Product Description

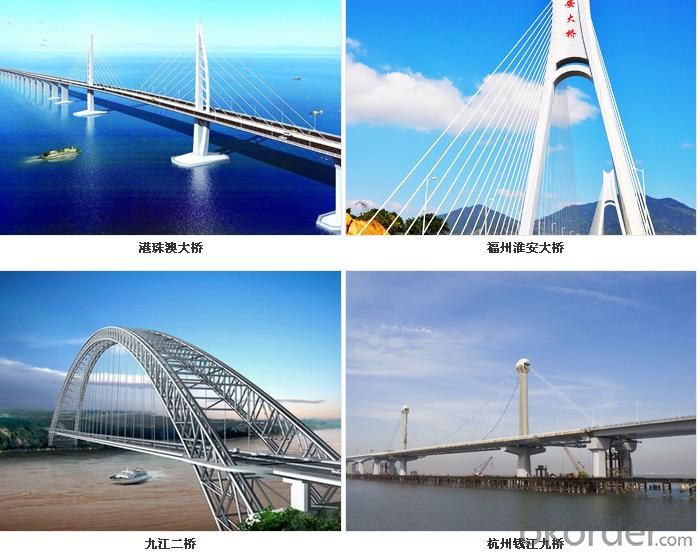

Application

- Support TIG & MMA two kinds of welding

- Adopts IGBT module technology

- Soft-switching technology bring higher effciency and more stable performance

- Automatic compensation for voltage fuctuation, can cork against input voltage fuctuation (V+/-15%)

- Over-voltage protection, undervoltage protection, over current protection, over load protection

- Suitable for welding with different kinds of acid or basic electrode, MMA support down weld with cellulose type electrode.

| Mode | TIG-400* | TIG-500* | TIG-630* |

| Type | IGBT module | ||

| Rated input voltage (V) | three phase AC380+/-15% | ||

| Rated frequency (Hz) | 50/60 | ||

| Rated input power (KVA) | 18.4 | 25 | 35 |

| Rated input current (A) | 28 | 38 | 52 |

| Output current (A) | 20-400 | 20-500 | 50-630 |

| Rated working voltage (V) | 36 | 40 | 44 |

| Drive adjustment (A) | 0-100 | ||

| No-load voltage (V) | 79 | ||

| Diameter of tungsten needle (mm) | 1.6-4.0 | ||

| Rated duty cycle (%) | 60 | ||

| Effciency (%) | 85 | ||

| Power factor | 0.93 | ||

| Protection grade | IP21 | ||

| Insulation grade | F | ||

| Net weight (KG) | 41.4 | 47.6 | 51 |

| Gross weight (KG) | 49.6 | 55.8 | 60 |

| Housing of machine | iron | ||

| Dimension of machine (mm) | 642x323x573 | 642x323x573 | 697x350x635 |

| Packing | Carton | Carton | Wooden box |

| Dimension of packing (mm) | 700x390x660 | 700x390x660 | 760x450x705 |

FAQ:

Acceptable payment term and way?

T/T,L/C, T/T + L/C,

Acceptable price term ?

FOB CNF CIF DDU CPT

Do you accept OA payment terms?

Yes, sure, but it normally depending on the order value

Do you have QC team?

Yeah, sure, our QC team is very important, they will keep the qualitycontrol for our products.

What is the validity of your quotation?

Normally 7 days.

What is your advantage?

24 hour quick response /Customer oriented/ Credit foremost/ Top quality Excellent

- Q: What are the biggest differences between DC and arc welding machines? What characteristics do they have? They are good at welding what kind of metal materials

- Inverter DC argon arc welding machine is a non welding gas shielded welding machine. It uses argon as protective gas and tungsten needle as electrode welding machine. It mainly welds stainless steel, copper, magnesium and other insoluble metals. Inverter DC arc welding machine, welding machine DC welding by manual welding machine, it is not an ordinary DC welding machine AC arc welding machine. The price is more expensive.

- Q: Can argon arc welding machine be used instead of plasma cutting machine?

- This is really impossible.The common point of argon arc plasma cutting is direct current high frequency arc ignition.The difference is thatArgon arc welding welding voltage is very low, about 10 volts to more than 20 volts.Plasma cutting machine no-load voltage of more than 200 volts, the operating voltage is more than 100 volts or even higher.

- Q: Argon arc welding machine on the ignition, note: switch is not bad, what is the matter?

- The high frequency arcing part is out of order, mainly the high frequency arc starting control loop. So that it has no arc command (press the welding switch), the arc circuit has been connected.

- Q: There are several argon arc welding machines in our factory. There is a problem with it. To put it plainly, sometimes it can lead to arc. Sometimes it is very close and can not arc. Abnormal welding. Come on, master!

- The welding machine needs cleaning. There are two pieces of copper in it. The electric shock can be cleaned or a little closer, and the welding machine itself may be cold

- Q: Argon arc welding machine automatic leakage, how to repair?

- First of all, the power off state, look, out of breath Two cases. First, vent, OK, you're lucky, but the solenoid valve is broken. Change a few tens of dollars. Two, do not vent the gas, the circuit is out of order, you need some electrical knowledge. 1, check line, along the two lines of solenoid valve to the circuit board, control its relay, replace it. If it's not good, then if you're a little level, you'll continue to know how to do it at this step. If you don't know, then I'll say yes. Recommend professional maintenance.

- Q: Excuse me: reallink argon arc welding field effect transistor K2698 can use IRFP460 substitution?

- Can completely replace IRFP460, voltage and K2698 equal 500 volts, the current is slightly larger, 20 g under normal temperature, other technical parameters are the same

- Q: Common faults and maintenance methods of DC invert manual arc welding machineWho has the relevant circuit diagram?For example, the market style: ZX7-200, MMA-160, ARC-200 and other modelsWhat does the letter "ZX7 MMA ARC" mean?Are they all invert DC manual arc welding machines?

- Looking for manufacturers, each manufacturer's circuit is not exactly the same.

- Q: How can the argon arc welding machine adjust the operating voltage range?

- When the argon welder is constant current, the operating voltage varies with the operating current, and no adjustment is needed. If the work voltage is changed forcibly, the welding machine will not work properly

- Q: What's the difference between WSM argon arc welding machine and TIG argon arc welding machine?

- WSM: TIG welding electrode arc welding welding machine.TIG: tungsten inert gas arc welding. Tungsten argon arc welding.W: the first letter of tungsten (tungsten), which represents tungsten arc welding.S: Manual (welding). No manual TIG welding arc welding.M: pulse, the initial letter of the word "pulse". Represents the welder to support pulse output.TIG:Tungsten, Ienrt, Gas English abbreviation.The difference is that WSM supports DC TIG welding TIG welding electrode arc welding. TIG is a single tungsten argon arc welding. The former has more functions than the latter.

- Q: High frequency automatic discharge of argon arc welding machine, professional engineers? Yangcheng anda TIG-250 inverter argon arc welding machine to control the line to take high frequency or discharge can be welded, but not stable, no gas output, what is wrong with the place, please Engineer pointing. Thank you

- Look at what you are saying, not just the high frequency automatic discharge, but finishing the welding machine in the working state, which is equivalent to press the gun switch. Try to switch the gun off the boat socket. If it is not good, check the boot part on the circuit board. Normally, the relay is switched on before it is activated. See if the relay is out of order. The gas output section depends on whether there is a voltage to the solenoid valve. Some words is that the solenoid valve is broken, there is no circuit board is broken.

Send your message to us

Inverter DC TIG/MMA Welding Machine (IGBT Module type)

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 100 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords