Evacuated Tube Solar Collectors Metal Glass Heat Pipe Model SC-HM

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 set

- Supply Capability:

- 1500 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

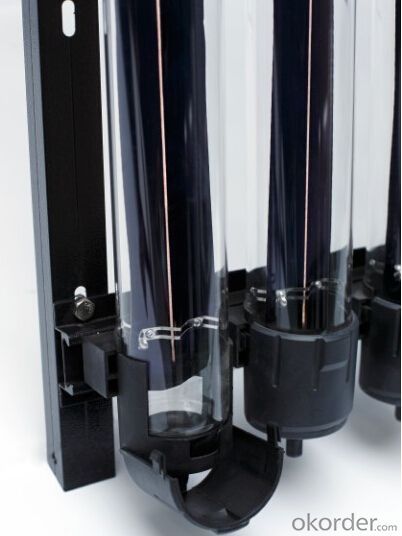

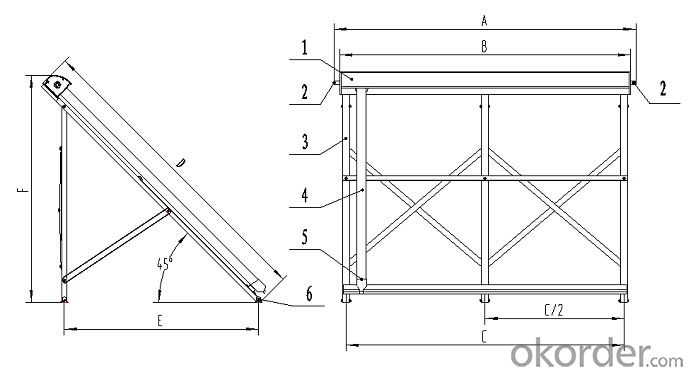

1. Structure of Metal Glass Heat Pipe for Solar Collector Model SC-HM

This Metal Glass Heat Pipe is an important part for solar collector, and the components are following as shown with graphic:

1 Manifold

2 Inlet & Outlet

3 Bracket

4 Metal Glass Vacuum Tube

5 Pipe Supporter

6 Anti-wind Foot

2. Main Features of Metal Glass Heat Pipe for Solar Collector Model SC-HM

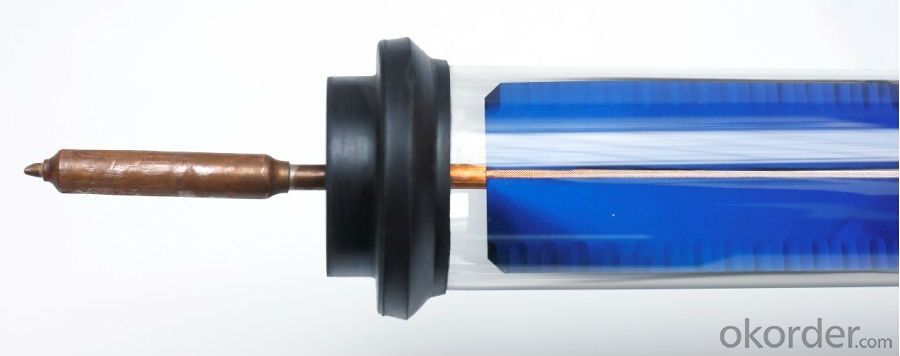

The Metal glass vacuum tube is sealed together, high temperature, anti-freezing, insulation with vacuum.

Withφ70 vacuum tube, large collecting area, strong heat collecting efficiency, high temp, rapid heat conducting.

Aluminum alloy manifold & bracket weight less, the surface has treatment of oxidation. It can withstand corrosion resistance.

The super thick insulation layer is Molded rock wool/mineral wool, with high density & low coefficient of heat conductivity

The flow chute is made of high quality brass, with pressure and corrosion resistance, high purity and can withstand 1MPa pressure.

Adjustable pipe supporter and easy for installation.

3. Metal Glass Heat Pipe for Solar Collector Model SC-HM Images

4. Metal Glass Heat Pipe for Solar Collector Model SC-HM Specifications

Model No. | SC-HM-10 | SC-HM-15 | SC-HM-18 | SC-HM-20 | SC-HM-24 | SC-HM-25 | SC-HM-30 |

No.of Vacuum Tube(PCS) | 10 | 15 | 18 | 20 | 24 | 25 | 30 |

Tube Space(㎜) | 100 | 100 | 100 | 100 | 100 | 100 | 100 |

OD/L of Vacuum Tube(㎜) | φ70/2000 | φ70/2000 | φ70/2000 | φ70/2000 | φ70/2000 | φ70/2000 | φ70/2000 |

Material of Vacuum Tube | Borosilicate glass 3.3 | Borosilicate glass 3.3 | Borosilicate glass 3.3 | Borosilicate glass 3.3 | Borosilicate glass 3.3 | Borosilicate glass 3.3 | Borosilicate glass 3.3 |

Material/Thickness of Heat Pipe(㎜) | Coppertp2/0.6 | Coppertp2/0.6 | Coppertp2/0.6 | Coppertp2/0.6 | Coppertp2/0.6 | Coppertp2/0.6 | Coppertp2/0.6 |

OD/Thickness of Flow Chute(㎜) | φ35/1.0 | φ35/1.0 | φ35/1.0 | φ35/1.0 | φ35/1.0 | φ35/1.0 | φ35/1.0 |

OD of Outlet & Inlet | φ22 or 3/4″ | φ22 or 3/4″ | φ22 or 3/4″ | φ22 or 3/4″ | φ22 or 3/4″ | φ22 or 3/4″ | φ22 or 3/4″ |

Insulation Material/Thickness(㎜) | Rockwool/40 | Rockwool/40 | Rockwool/40 | Rockwool/40 | Rockwool/40 | Rockwool/40 | Rockwool/40 |

Working Pressure(MPa) | 0.6 | 0.6 | 0.6 | 0.6 | 0.6 | 0.6 | 0.6 |

Working Temp ℃ | <150 | <150 | <150 | <150 | <150 | <150 | <150 |

Capacity of Solar Collector(L) | 0.69 | 0.98 | 1.15 | 1.27 | 1.50 | 1.56 | 1.85 |

Collecting Area(㎡) | 1.37 | 2.05 | 2.46 | 2.73 | 3.28 | 3.41 | 4.10 |

Total Area(㎡) | 2.20 | 3.28 | 3.92 | 4.35 | 5.21 | 5.43 | 6.50 |

Flow Rate(L/min) | 1.06 | 1.49 | 1.79 | 2.0 | 2.4 | 2.5 | 3.0 |

drop of pressure (Pa) | 16.24 | 41.4 | 63.4 | 81.7 | 127.2 | 140.1 | 219.8 |

Intercept efficiency η0 | 0.77 | 0.77 | 0.77 | 0.77 | 0.77 | 0.77 | 0.77 |

Heat loss rate a W/㎡℃ | 1.9 | 1.9 | 1.9 | 1.9 | 1.9 | 1.9 | 1.9 |

Efficiency(W)1000W/㎡irradiation | 744 | 1044 | 1256 | 1398 | 1681 | 1748 | 2098 |

N.W(kg) | 40.25 | 52.75 | 61.75 | 66.75 | 81.00 | 85.35 | 100.70 |

a (㎜) | 1115 | 1615 | 1915 | 2115 | 2515 | 2615 | 3115 |

b (㎜) | 1025 | 1525 | 1825 | 2025 | 2425 | 2525 | 3025 |

c (㎜) | 950 | 1450 | 1750 | 1950 | 2350 | 2450 | 2950 |

c/2 (㎜) | —— | —— | 875 | 975 | 1175 | 1225 | 1475 |

d (㎜) | 2150 | 2150 | 2150 | 2150 | 2150 | 2150 | 2150 |

e (㎜) | 1375 | 1240 | 1240 | 1240 | 1240 | 1240 | 1240 |

f (㎜) | 1590 | 1590 | 1590 | 1590 | 1590 | 1590 | 1590 |

5. FAQ

1. What happens if one of the solar tubes is broken?

Firstly, tubes are very strong and not easily broken, but if the worst should happen, solar tubes can be replaced very easily. They are inexpensive and available. The solar collectors can operate with several broken tubes, but the efficiency will be reduced, so it is recommended that broken tubes be replaced immediately.

2. Can the solar collectors be mounted on a flat surface?

Yes they may be mounted on a flat roof or on the ground by using a stainless steel Flat Roof Frame. The collector should be installed at a minimum of 20o angle to ensure optimal operation of the heat pipe.

3. Will the solar collector be a fire hazard during hot, dry weather?

No. The solar collector's components are all high temperature rated and non-flammable, so even during strong sunlight with the circulation pump turned off (stagnation), the system will not catch alight or give off any sparks. The majority of the solar collector's components are stainless steel, aluminium, glass or glass wool. The manifold outlet should be fitted with a temperature relief valve, which will prevent the manifold temperature from exceeding 99oC / 212oF.

- Q: Can solar collectors be used for heating retirement homes and assisted living facilities?

- Yes, solar collectors can certainly be used for heating retirement homes and assisted living facilities. Solar thermal systems can efficiently capture and store the sun's energy to provide heat for water and space heating needs in these facilities. By utilizing solar collectors, retirement homes and assisted living facilities can reduce their dependence on traditional heating systems and lower energy costs while also contributing to a greener environment.

- Q: How do solar collectors affect community engagement?

- Solar collectors can positively impact community engagement in several ways. Firstly, the installation and use of solar collectors can raise awareness and inspire discussions about renewable energy and environmental sustainability within the community. This can lead to increased engagement and participation in local initiatives aimed at promoting clean energy and reducing carbon emissions. Additionally, solar collector projects often involve collaboration between community members, local organizations, and government bodies, fostering a sense of unity and shared responsibility. Finally, by reducing reliance on fossil fuels and empowering communities to generate their own clean energy, solar collectors can contribute to energy independence and resilience, further strengthening community engagement and self-sufficiency.

- Q: Can solar collectors be used at night?

- No, solar collectors cannot be used at night as they rely on sunlight to generate electricity or heat.

- Q: Can solar collectors be used for heating in tropical regions?

- Yes, solar collectors can indeed be used for heating in tropical regions. Despite the abundance of sunlight in these regions, solar collectors can still effectively harness solar energy to provide heating for various purposes such as water heating, space heating, or even air conditioning. The use of solar collectors in tropical regions can contribute to energy efficiency, reduce reliance on fossil fuels, and lower greenhouse gas emissions.

- Q: Can solar collectors be used for heating aquariums?

- Yes, solar collectors can be used for heating aquariums. Solar collectors use sunlight to generate heat, which can then be used to warm the water in an aquarium. This is an eco-friendly and cost-effective way to maintain the desired temperature in an aquarium.

- Q: Can solar collectors be used for drying construction equipment?

- Yes, solar collectors can be used for drying construction equipment. The heat generated by the solar collectors can be utilized to dry out the equipment, helping to remove moisture and prevent rust or damage.

- Q: Can solar collectors be used in conjunction with other heating systems?

- Yes, solar collectors can be used in conjunction with other heating systems. Solar collectors can provide a supplemental source of heat to complement existing heating systems, such as boilers or radiant floor heating. This integration allows for a more sustainable and cost-effective heating solution, as solar energy can be harnessed during sunny periods, while traditional heating systems can be used during periods of low solar radiation or high heat demand.

- Q: Can solar collectors be used in residential areas?

- Yes, solar collectors can be used in residential areas. In fact, they are increasingly being installed in homes to harness renewable energy from the sun and reduce dependence on traditional power sources. Solar collectors can be mounted on rooftops or integrated into building designs, making them a viable and sustainable option for residential energy needs.

- Q: Do solar collectors require direct sunlight to work effectively?

- Solar collectors do not necessarily require direct sunlight to work effectively. While direct sunlight is ideal for optimal performance, solar collectors can still generate electricity or heat even on cloudy or overcast days. The efficiency of solar collectors may be slightly reduced in these conditions, but they can still harness the diffuse sunlight and convert it into usable energy. Additionally, some advanced solar collector technologies, such as concentrator photovoltaic systems, are designed to concentrate and intensify sunlight, allowing them to work more effectively even in indirect or low-light conditions. Overall, while direct sunlight is preferable, solar collectors can still function and produce energy in various lighting conditions.

- Q: Can solar collectors be used in areas with limited access to training?

- Yes, solar collectors can be used in areas with limited access to training. Solar collectors are relatively simple and can be installed and operated with basic knowledge. Additionally, there are numerous online resources, manuals, and instructional videos available that provide step-by-step guidance on how to install and maintain solar collectors. Therefore, even in areas with limited access to training, individuals can still learn and adopt solar technology for their energy needs.

Send your message to us

Evacuated Tube Solar Collectors Metal Glass Heat Pipe Model SC-HM

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 set

- Supply Capability:

- 1500 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords