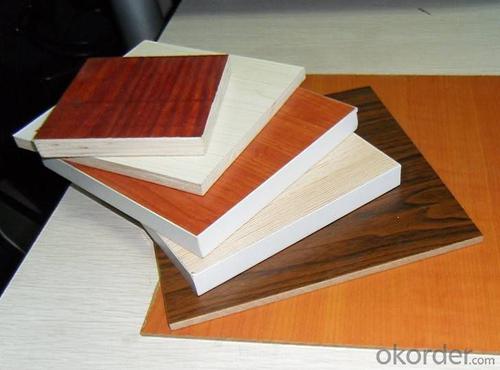

3/4 Plywood 4x8 Melamine Faced Commercial Plywood for Bed Usage

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m³

- Supply Capability:

- 100000 m³/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

Commercial Plywood

1.face/back:bintangor/okoume/pencil cedar and other hardwood

2. poplar or hardwood or finger joint as core

3.1220x2440x5-18mm

3.grade:bbcc

4.glue:MR/E2

Melamine Plywood Description:

core | poplar,hardwood,combi,eucalyptus,etc |

face/back | okoume,bintangor,pencil cedar,etc |

grade | bbcc grade |

glue | MR, E2, |

moisture | 12-16% |

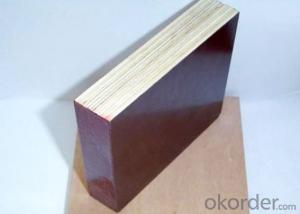

thickness | 5-18mm |

tolerance | ≤6mm:0.3mm; ≥6mm:0.5mm |

pressed | two time hot press |

size | 1220*2440/ 1220*1830/ 910*1830/ 910*2130 |

usage | furniture/wooden pallets,plywood boxes,etc |

packing | pallet packing |

payment | T/T,L/C at sight |

delivery time | within 15 days after receiving deposit |

Product Features:

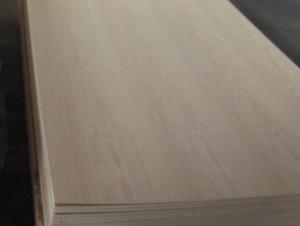

1.Good wear-resisting, scratch-resistant, heat resistant, resistant to pollution, steam resistance and other properties

2.Structure performance is better than MFC and MDF: bigger bending strength, stronger nail-holding ability, smaller absorbing water thickness expansion rate that can waterproof soak for a long time without delamination.

3.Especially suitable for humid environment or demanding situations

FAQ:

1. samples are available

2. discount is allowed for big orders

3. welcome to our factory for a visit at anytime

- Q: according to the use of plywood can be divided into needle plywood and broadleaf plywood.

- the minimum number of layers of each nominal thickness to comply with the relevant provisions.

- Q: Class I resistant weather plywood Class II water resistant plywood

- slab molding (mixing resin and additives pavement), under hot pressure, so that cellulose and Hemicellulose and lignin plasticized to form a plate.

- Q: According to the different composition of the glue, for the construction of plywood with the following types of glue

- According to the environmental protection level, the glue used for plywood can be divided into E0 grade, E1 glue, E2 glue (and even E2 level are not reach the unqualified glue)

- Q: Plywood is a common material for furniture?

- The number of layers is generally odd, and few are even. Vertical and horizontal direction of the physical and mechanical properties of small differences.

- Q: Plywood is generally used in applications where the strength and stability of the material are relatively high

- It can be installed directly. It can be made of concrete frame structure and formwork.

- Q: The Preparation of plywood ingredients

- core core core sandwich panel or composite plywood center layer. Usually its thickness is greater than the other layers.

- Q: Why is the plywood commonly used in the singular layer

- if put a piece into a striped. (Then this time there will be positive is the pattern of wood

- Q: Poisoning diagnosis and grading standards

- chronic benzene poisoning and blood cell involvement and the series and extent, and whether the evil is divided into light, medium and heavy three.

- Q: What are the types of veneer veneer veneer?

- according to water resistance can be divided into class I decorative veneer veneer plywood, Veneer plywood and class III decorative veneer veneer plywood

Send your message to us

3/4 Plywood 4x8 Melamine Faced Commercial Plywood for Bed Usage

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m³

- Supply Capability:

- 100000 m³/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords