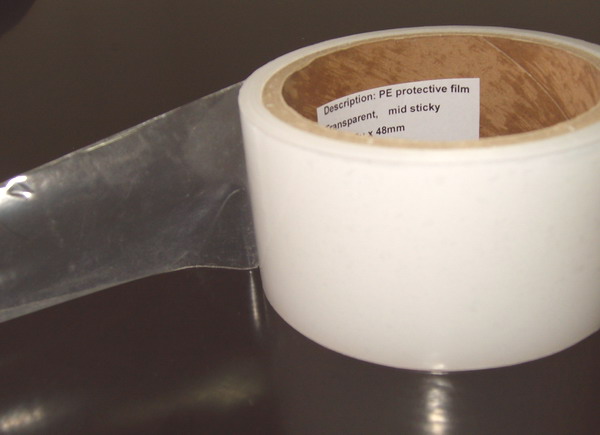

Medium Tack PE protective flim HN-80

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Construction: LDPE film + water based acrylic

Total Thickness (adhesives + carrier):80+10%micron

Colour: Black & White

Density 0.95g /cm3

Tensile Strength (Long): >18N/25mm

Tensile Strength (Trasv): >13N/25mm

Adhesion (to stainless steel):150g/25mm

Elongation at break-MD: >200%

Elogation at break-CD: > 350%

Static Shear 23 DC: >48 hours

Storage: 35 DC

Humidity: 80%

Shelf: 6 months

- Q: How to wipe off the marks on the protective filmmade by something adhesive ?

- Dipping some cotton in alcohol and wiping them off~ ~ That will be fine! ! It worked really well~ ~ And it disinfected the screen as well ^_^

- Q: How to distinguish release film from protective film with the naked eye?

- In fact, the protective film is relatively the use layer. It's thicker than release film. But release film is used to protect the use layer. Usually, PET use layer can not only be formed by PET release film, but also by PE release film. To put it simple, generally the middle layer is the use layer. The outer layers are all release film which are usually thinner than the use layer.

- Q: How to test the adhesion of protective film?

- There's a special equipment for tension testing! The protective film you are saying may be silicone PET, generally having adhesion of 2 g - 10 g. High-quality ones have excellet performence in eliminating bubbles.

- Q: How to distinguish the adhesion degrees of Protective film materials?

- It depends on what exact kind of product the customer want. Certain product has certain function and degree of adhesion. 1N or less refers to low degree of adhesion; 1-3N refers to medium degree, and 3N or more, high degree. In addition, there are also slight degree and super degree somewhere.

- Q: How to get off the dust attached to the mobile phone protective film?

- It's difficult to remove the dust, I suppose. You can use a bank card to get rid of the bubbles.

- Q: PET protection film sticking is not firm, how to solve?

- Rainbow pattern is now PET protection film material often encountered problems, because PET protective film material surface hardening treatment, hardening is to be treated by high temperature,

- Q: How can the protective film on the outer layer of the stainless steel thermos cup be removed?

- The protective film on the outer surface of the stainless steel thermos cup can be removed by the following methods:1, with paper towels stained with some alcohol (preferably with industrial alcohol, not to use medical also OK) wipe, and then rub a few stainless steel protective film on the clean.2. Use nail polish. The usage is similar to alcohol acetone. The effect is also good. Washing water does not require quality, good or general, as long as you can wash off all nail polish.

- Q: What are the conditions for the production of PET protective films?

- Two, industry standards: industry standards refers to national standards within the scope of all industries. The "standard law" stipulates: "there is no national standards and there is a need in a nationwide industry within the unified technical requirements, you can formulate industry standards.". The industry standards shall be formulated by the relevant administrative departments under the State Council and submitted to the administrative department for standardization under the State Council for the record. After the publication of the national standard, the industry standard will be abolished." National standards and industry standards are national standards applicable.

- Q: Do I need to tear off the protective films on household appliances?

- Yes, you need to. It will be good to the heat dissipation of the appliances this way! And the visual effect is better this way too.

- Q: What are the main components of PE protective film?

- Polyethylene film is the main component.

Send your message to us

Medium Tack PE protective flim HN-80

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords