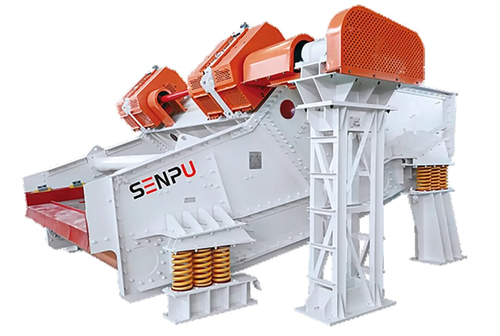

MDMS-VB Banana ScreenMDMS-VB Banana Screen DMS-VB/MDMS-VB linear vibrating screen

- Supplier:

TANGSHAN ZHONGQING MACHINERY CO.,LTD

TANGSHAN ZHONGQING MACHINERY CO.,LTD

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 30 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

The screen is suitable for the dewatering, deintermediation

and classification of lump coal, fine coal or other similar

materials. It offers a series of advantages, including high

capacity, low vibrating noise, screen boxes free maintenance,

easy replacement and overhaul of screen plates, satisfactory vibration reduction, power consumption less than domestic

screen with the specifications. It has been granted 2 national

patents. Now, 15 sizes ranging from MDMS1848-VB to MDMS 4373-VB are available.

The screen is suitable for the dewatering, deintermediation

and classification of lump coal, fine coal or other similar

materials. It offers a series of advantages, including high

capacity, low vibrating noise, screen boxes free maintenance, easy replacement and overhaul of screen plates, satisfactor y vibration reduction, power consumption less than domestic screen with the specifications. It has been granted 2 national patents. Now, 40 sizes ranging from DMS1836-VB/ MDMS1836-VB to DMS 4373-VB/MDMS4373-VB are available.

- Q: What is the magnitude of vibration before and after the horizontal vibrating screen 220?

- The weight of the eccentric block: increasing the weight of the eccentric block (increasing the eccentric weight) can increase the amplitude of the vibrating screen. The lower eccentric block controls the upper and lower amplitudes of the vibrating screen, and the upper eccentric block controls the left and right amplitudes of the vibrating screen

- Q: What is the influence of eccentric vibration of the vibrating screen on the rolling bearings?

- The vibration exciter used in vibration screen is mostly eccentric shaft exciter and box type vibration exciter. Eccentric bearing vibration device has convenient installation and adjustment, but the cost is high, and the eccentricity is not adjustable; box vibrator with adjustable to the relative position of the fan-shaped eccentric block, can realize the vibrating force adjustment, so as to achieve the purpose of adjustable amplitude.

- Q: Circuit principle and connection method of Derek vibrating screen

- The whole control cabinet does not work all the way or a few ways, the alarm light is on, check whether the fuse of this road is broken, whether the thyristor is damaged or shorted, and whether the electromagnetic vibrating coil is burned out,

- Q: Domestic ultrasonic vibration sieve power supply transducer, which is better?

- Are almost the same, not to do any good, because the work principle, there is to see which in the selection of electronic fittings, ceramic pellet, materials and so on is good things, responsible attitude and workers in the installation work. At present, there is no home to do is unique, more distinctive, or stability is better

- Q: What are the advantages of the layout of a linear vibrating screen?

- Because the eccentric heavy blocks of the two machines are implicated each other and produce inertia complementary action, the utility model can save energy about 60% more than the two machines. When the utility model is stopped, the whole system has small following motion, fast parking and short resonance time

- Q: What is the quality of the vibrating screen related to the factors?

- We should evaluate the quality of a vibrating screen, but it depends on the quality of the vibrating screen, and the quality of the work depends on its efficiency and the size of the workload.

- Q: Can the linear vibrating screen not be horizontally placed? How big is the dip angle?

- The effect of horizontal placement is that the performance parameters of the screening machine can be rationally configured to obtain good material running speed and processing capacity and higher screening efficiency.

- Q: How do you use mathematical equations to figure out how large the sieve is and what size it is to sieve out?

- Your raw material (coarse aggregate) is too thin, most of which is lower than 20mm, so in the mixture you find more than 20mm of the material is very small. Raw material is not qualified.

- Q: How many methods do you use to fix the screen surface of vibrating screen?

- Bolt compression and fixation bolt fastening and fixing: refers to the use of bolts to compress the screen surface on the screen frame connection. The fixing method is suitable for the sieve plate with a thickness of more than 8mm, a rubber screen surface, a bar screen surface and a central fixing screen of a large sieve diameter yarn. There are two forms of bolts: U and J. The difference is that the U is more cumbersome than the J and is often used in the J model.

- Q: How does a vibrating screen work in a rock yard? What is its principle?

- Stone powder: stone powder is generally known as "stone powder", a variety of stones, according to the mineral composition, there are many varieties, not necessarily calcium carbonate. Calcium carbonate is limestone, but only a kind of stone powder, stone powder and talcum powder, used for making putty. And quartz powder used as support glass. There are many mineral components of rock that can be ground into powder for different processes and uses!

Send your message to us

MDMS-VB Banana ScreenMDMS-VB Banana Screen DMS-VB/MDMS-VB linear vibrating screen

- Supplier:

TANGSHAN ZHONGQING MACHINERY CO.,LTD

TANGSHAN ZHONGQING MACHINERY CO.,LTD

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 30 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products