Speed Packaging Tape Masking Film with Corona Treatment for Plastic

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 roll

- Supply Capability:

- 30000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Masking Film Painting Usage Corona Treatment Plastic

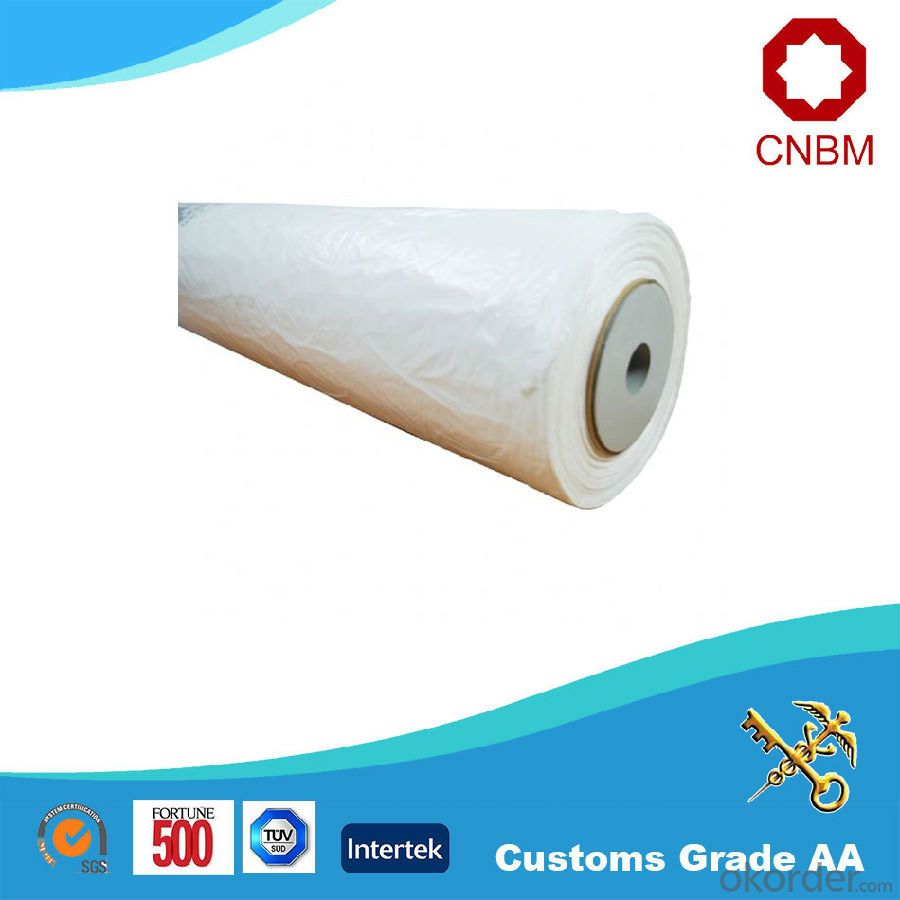

1. Structure of Masking Film Description

Masking Film is of HDPE film and masking tape. A convenient, pretaped plastic film which unfolds to cover and protect various surfaces while painting. Specially treated film clings to surfaces and is easy to clean up.

2. Main Features of Masking Film

Multi-Folded easy to use;

Strong and Flexible;

Competitive price

Indoor/outdoor painting

Sunlight stable even on glass

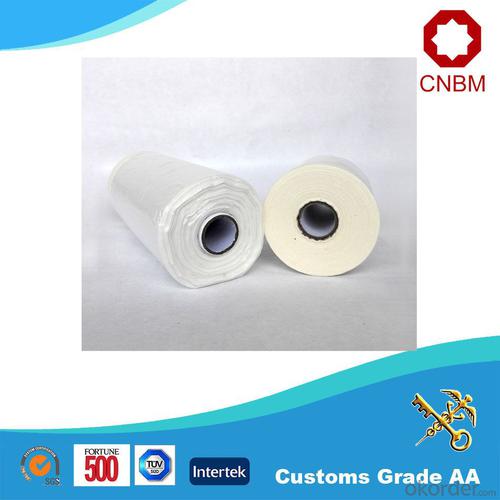

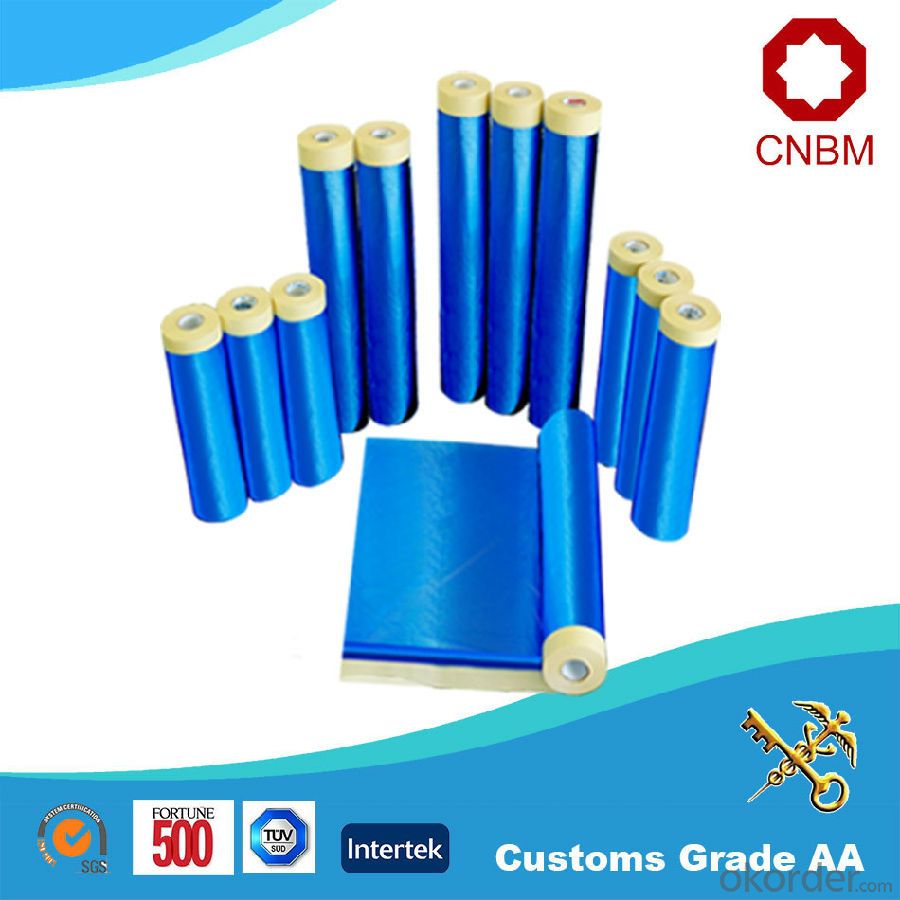

3. Masking Film Images

4. Masking Film Specification

Tape Size | Rolls/Carton | Weight/Roll(kg) | Jointing Material | Temperature Resistance |

330mm*30M | 20 | 0.12 | Crepe parer | -5—60°C |

550mm*30M | 50 | 0.17 | Crepe parer | -5—60°C |

1100mm*30M | 25 | 0.30 | Crepe parer | -5—60°C |

1400mm*30M | 10 | 0.39 | Crepe parer | -5—60°C |

5. FAQ

Q1. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

Q2. What is our company?

CNBM International Corporation is a state-owned company. As World Top 500 Company, we have clients from over 120 countries and overseas branches in 5 countries. We specialized in adhesive tape for over 20 years, with SGS and ISO9001 certified and Grade AA for Export.

Q3. How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

- Q: Can packaging tape be used for sealing fabric or textiles?

- No, packaging tape is not suitable for sealing fabric or textiles as it may not adhere properly and could damage the material. It is recommended to use fabric-specific or textile adhesive tapes for this purpose.

- Q: Does packaging tape come in different materials for specific applications?

- Yes, packaging tape does come in different materials for specific applications. These materials include polypropylene, PVC, paper, and filament tape. Each material has unique properties that make it suitable for various purposes such as sealing lightweight packages, securing heavy boxes, or providing extra strength and tear resistance.

- Q: Does packaging tape come with a dispenser?

- Packaging tape often comes accompanied by a dispenser, aiming to facilitate and optimize the application of the tape onto packages. The dispenser is usually equipped with a handle, granting you the ability to firmly grasp and manage the tape while sealing boxes or packages. This eliminates the necessity of manually cutting the tape, as well as prevents any entanglement or wastage. However, it is crucial to acknowledge that not all packaging tapes are bundled with a dispenser. Some tapes may require separate purchase, whereas others may be conveniently offered as a set, inclusive of the dispenser. It is always advisable to consult the product description or packaging for confirmation regarding the inclusion of a dispenser alongside the packaging tape.

- Q: Can packaging tape be used for sealing PVC pipes?

- No, packaging tape should not be used for sealing PVC pipes. PVC pipes require a specific type of sealant that is designed to bond with the PVC material and create a watertight seal. Packaging tape is not designed for this purpose and may not provide a secure and durable seal. It is recommended to use PVC pipe sealant or plumber's tape specifically designed for sealing PVC pipes to ensure a proper and long-lasting seal.

- Q: How does packaging tape affect the weight of a package?

- Packaging tape does not directly affect the weight of a package. The weight of the package is determined by the contents inside, such as the product being shipped, any additional packaging materials, and the actual weight of the packaging itself. Packaging tape is used to secure the contents of the package and ensure that it remains intact during transit. While the tape itself may weigh a small amount, it is negligible compared to the overall weight of the package. Therefore, the packaging tape does not significantly impact the weight of a package.

- Q: Can packaging tape be used on different materials?

- Yes, packaging tape can generally be used on different materials. It is commonly used to seal cardboard boxes, but it can also adhere to materials such as plastic, metal, and wood. The adhesive on packaging tape is designed to provide strong adhesion on a variety of surfaces, making it versatile for different packaging needs.

- Q: Can packaging tape be used for sealing office supplies or stationery?

- Certainly, office supplies or stationery can be sealed using packaging tape. This adhesive tape is highly versatile and frequently employed for sealing packages and boxes. Yet, it is crucial to take into account the size and weight of the item when using packaging tape for sealing smaller objects like office supplies or stationery. If the item is lightweight and the packaging tape is not excessively wide or bulky, it can serve as a convenient and effective option for sealing. Nevertheless, for smaller items, it might be more appropriate to utilize alternative types of tape, such as clear tape or double-sided tape, which are specifically designed for sealing stationery and office supplies.

- Q: Is packaging tape safe to use on painted surfaces?

- Packaging tape is generally safe to use on painted surfaces, but there are a few factors to consider. Firstly, it is important to ensure that the paint is fully cured before applying any tape. This typically takes around 30 days, depending on the type of paint used. Applying tape to fresh or uncured paint can cause damage when the tape is removed. Secondly, the type of tape used can also make a difference. Most packaging tapes are designed to be easily removable without leaving residue or causing damage to surfaces. However, some low-quality tapes or tapes with strong adhesives may leave behind sticky residue or even peel off the paint when removed. It is recommended to use high-quality packaging tape that is specifically labeled as safe for painted surfaces. To be on the safe side, it is always a good idea to test the tape on a small, inconspicuous area of the painted surface before applying it extensively. This will help you ensure that the tape does not cause any damage or leave residue behind. If there are any concerns, it is advisable to consult the manufacturer's instructions or seek professional advice. Overall, when used properly and on fully cured paint, packaging tape should be safe to use on painted surfaces. However, it is important to exercise caution and choose the right tape to prevent any potential damage.

- Q: Is packaging tape resistant to mold or mildew?

- Yes, packaging tape is generally resistant to mold or mildew.

- Q: Can packaging tape be used for sealing wooden crates?

- Yes, packaging tape can be used for sealing wooden crates. It provides a strong and secure seal to keep the contents of the crate safe during transportation or storage.

Send your message to us

Speed Packaging Tape Masking Film with Corona Treatment for Plastic

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 roll

- Supply Capability:

- 30000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords