Manhole Cover EN124 D400 Made in China on Hot Sale

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

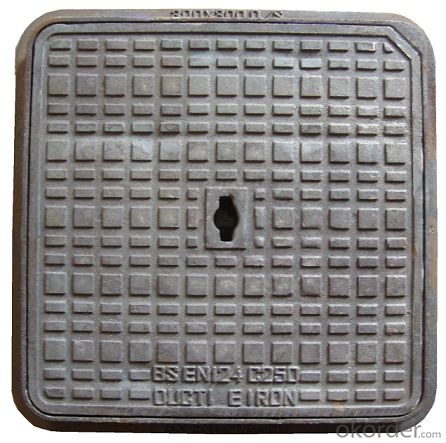

1.Cast Iron Manhole Cover Description :

Manhole covers are often made out of cast iron, concrete or a combination of the two. This makes them inexpensive, strong, and heavy, usually weighing more than 50 kilograms (110 lb). The weight helps to keep them in place when traffic passes over them, and makes it difficult for unauthorised people not having suitable tools to remove them.

2.Main Features of the Ductile Iron Manhole Cover:

1. Designed structure & pressure dispersion

Arc-shaped bottom structure allows the pressure they bear disperse averagely on the whole surface. Besides, the products are made not by SMC, it was put in several layers of fiber cloth to enhance the structures. So they are stronger than SMC composite manhole covers.

2. Consequences of temporarily overloading

Temporarily overloading may cause smash of concrete covers, seriously deformation, even slightly split. But this will not happen to FRP fiber cloth manhole cover.

3. Safety options

There is no metal contain, directly reducing potential accident or further maintenance costs caused by thieves. Anti-slip surface offer a safe road condition even in extreme weather.

3.Manhole Cover Images:

4.Manhole Cover Specifications:

1) Production information

Manhole cover are manufactured for construction and public use. Manhole cover shall be smooth and free sand holes, blow holes, distortion or any other defects

2) Process

A) Molding boards

B) Hand Casting

3) Coating

A) black bitumen or epoxy .

B)Coating as per customer's requirement

4) Different accessories are available

5) Packing:

Wooden case or wood pallet, or as per customers' requirement

5.FAQ:

We have organized several common questions for our clients,may help you sincerely:

Q. I have a heavy traffic manhole cover but it has been broken by a forklift, why?

A. Forklifts have solid wheels which apply pressure differently to standard pneumatics and therefore covers must be specially adapted to suit this.

Q. The project I’m working on requires a manhole cover with a quality finish, what’s available?

A. Naturally, galvanised steel of black polypropylene aren’t always ideal, and so we offer brass or stainless steel edging, as well as complete stainless steel covers.

However, the best way to obtain easy access is to have a bespoke, hinged manhole cover.

- Q: Why does the surface of stainless steel casting mirror mirror ripple?

- Those should be head prints. If required, it would be better to throw with a single grinding head.

- Q: Explain the heat treatment effect of casting parts, forging parts and welding parts

- The three methods of metal processing have one thing in common. They are hot working, which are different in temperature and range of processing. Ductile cast iron is widely used because of its brittleness and poor impact. Heat treatment of cast iron usually adopts the annealing process, reduce the casting effect: 1 because of the internal stress caused by the thermal expansion and contraction, reduce the deformation after machining, decrease surface hardness, improve machining conditions;

- Q: Domestic large steel castings factory which is better, recommend!

- At least spend money on research and development, then the quality should be all right.

- Q: Is the cast steel a casting part?

- Yes, molten steel is poured into the mold and cooled to become a casting. Can also cast iron, cast aluminum, plastic casting.

- Q: The casting sand is going on

- 2, causes(1) sand mold (core) strength is not high, when the box a little reason will fall off.(2) the strength of sand mould (core) is not high, it can not stand the erosion of molten steel.(3) box sand mould (core) crush.(4) high strength under high temperature, warpage, deformation and protuberance into the cast steel under the action of high temperature molten steel.(5) the floating sand in the air hole of the sand mold falls, especially when the floating sand falls in the casting, and the floating sand on the surface of the sand mold is easy to fall through the air vent.(6) when the box is closed, the surface of the mold cavity and the surface of the sand core are not cleaned, and the sand (core) surface has floating sand and so on.

- Q: What are the casting parts processing engineering?

- According to the classification of process methods, sand casting and special casting.

- Q: After reaming, the roughness can reach several levels, that is to say, the sample.Casting parts in rocker arm drilling, reaming, roughness, block. After reaming, the roughness can reach several levels, that is to say, the sample.

- The finish of reaming depends on the material and the sharpness of the reamer, as well as the speed and speed of the top and bottom. Marine machine tool

- Q: For example, casting parts contain many holes, inclusions and other defects, the size and the number of holes exceed which limit is not qualified

- According to different casting process and parts materials, each has relevant standards, can be found online;

- Q: Which surface is coarser for cast iron or cast steel castings? Why?

- Roughness mainly depends on the surface roughness on the surface of the sand.

- Q: Can the casting part be phosphating with the phosphating solution of the pickling board?

- If it is Phosphating for painting, it is not necessary, because the surface of the casting is rough and can be firmly bonded with the paint film.

Send your message to us

Manhole Cover EN124 D400 Made in China on Hot Sale

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords