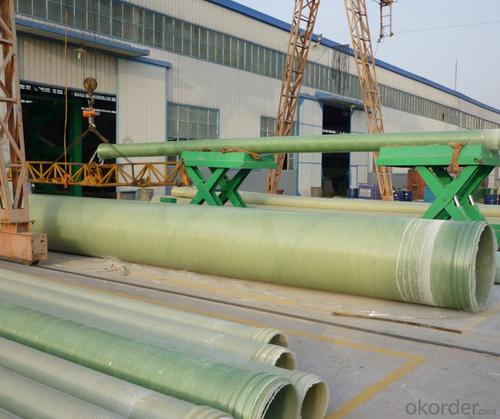

Maintenance Free FRP Composite Pipes without Consequent Pollution

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

COMPANT DESCRIPTION

CNBM,China National Building Materials Group is a state-owned enterprise in charge of administrative affairs in china building materials industry. Established in 1984, CNBM is a large group corporation of building materials with total assets of 25 billion RMB and a total staff of 30,000.CNBM now owns 200 subordinating firms of solely owned and joint-venture companies.

CNBM International Corporation is one subsidiary of CNBM, we focus on offering good-quality products,professional service and complete solution to our customers. Strong delivery capacity, advanced technology& management, strong financing capability and excellent after-sale service are our advantages in sharing international market.

PACKAGING & DELIVERY

1.Packaging Details:

standard packing or your requirement

2.Delivery Detail:

Shipped in 30 days after payment

PRODUCT DESCRIPTION

1.Pipe Introduction

It is the ideal product for the transportations of the chemicals, drinking water, waste water, waste gas and sewer.

2.Characteristics

1. High anti-corrosion capability, long designed service time of 20 years;

2. Good hydraulic property, smooth inner surface with absolute roughness of 0.01mm, which is far less than that of carbon steel pipe or cast iron pipe;

3. Lightweight and facility to install and transport;

4. High specific intensity and reliable mechanical performance;

5. Low thermo-conductivity and small thermo-stress, which are allowed to be used in various conditions: exposed buried or suspended, in ocean or in deserts, freezing or humid;

3.Technical Data

Stiffness | SN3750 | SN5000 | SN10000 | ||||||

Pressure | 0.25 | 0.6 | 1.0 | 0.25 | 0.6 | 1.0 | 0.25 | 0.6 | 1.0 |

400 | 6.1 | 6.1 | 5.9 | 6.7 | 6.7 | 6.4 | 8.1 | 8.1 | 7.87 |

500 | 7.2 | 7.2 | 7.1 | 8 | 8 | 7.7 | 11.4 | 9.6 | 9.4 |

600 | 8.7 | 8.3 | 8.3 | 9.6 | 9.6 | 9.2 | 12.1 | 11.7 | 11 |

700 | 9.7 | 9.7 | 9.4 | 11.2 | 11.2 | 10.4 | 13.8 | 13.2 | 12.5 |

800 | 11.6 | 11.3 | 10.6 | 12.8 | 12.5 | 11.7 | 15.5 | 15 | 14.2 |

900 | 13.4 | 12.5 | 11.7 | 14.8 | 13.8 | 12.9 | 19.3 | 16.4 | 15.8 |

- Q: Designed to support FRP pipes, is it m or mm?

- Glass fiber reinforced plastic cable protection tube, a resin based, continuous glass fiber reinforced fabric as reinforced material, through computer control, winding process or pultrusion process of forming a pipeline. The glass steel production process, high strength, good toughness, electrical insulation, flame retardant, good heat resistance, can not deform, at 100 degrees high temperature corrosion resistance, erosion resistance and long service life, acid salt and various organic solvents with corrosive media, with a life span of 50 years. Applicable to a wide range of glass for cable laying underground steel cable protection tube, play a protective role, but also can be used for cable bridge, stone and of high demand

- Q: FRP acceptance standard

- Perform hydrostatic test. In order to comprehensively check the installation quality of pipes, the pressure test shall be carried out according to the test methods stipulated in the code for construction and acceptance of water supply and drainage pipe works, and the allowable seepage water quantity shall be carried out according to the standards of the steel pipe.

- Q: FRP pipe and 0.7 thick galvanized pipe which cost is low?

- The best material in glass steel mould rubber production 20 years, customers in all aspects

- Q: Glass fiber reinforced plastic GRE pipe broken hole how to repair and repair?

- Resin selection of good points, the general also line, as well as accelerators, curing agents, high-quality glass fiber cloth.

- Q: What kind of project needs fiberglass pipe?

- Glass fiber reinforced plastic products are characterized by corrosion protection, high temperature resistance, humidity resistance, alkali resistance, etc., where it is necessary to use the glass fiber reinforced plastic pipe!!

- Q: What's the difference between glass fiber reinforced plastic pipe and glass fiber reinforced sand pipe?

- If the thickness of the pipe can meet the requirements of pressure, but can not meet the stiffness requirement, will choose to increase the thickness of sand to meet the stiffness (of course can not directly increase the sand thickness to meet the requirement of stiffness, but the cost is too high).

- Q: What is fiberglass communication tube?

- The appearance of glass fiber reinforced plastic communication tube is to make full use of the high strength, impact resistance and corrosion resistance of glass fiber reinforced plastic, so as to ensure the safety of the optical cable or cable in the pipe hole under the action of sudden outside force. However, the process of making glass steel pipes will cause some defects of FRP pipe in communication field, because there are a lot of glass tube or end of steel fiber in irregular stands, glass fiber of these irregular stands can pierce the cable protective rubber layer in the cable laying process, once exposed to in the optical fiber cable, will inevitably lead to deflection of light signal transmission, which seriously affects the quality of signal transmission, which is fatal to the communication network. The problem is solved by the steel tube off the glass.

- Q: What are FRP pipes?

- The glass steel base material and reinforcing material composition, because of different base material we have called GRE, some called GRP, the matrix material is generally resin reinforced material is glass fiber, adding other raw materials in the production process to obtain more excellent performance, such as adding graphite or carbon fiber can be obtained antistatic, using phenolic resin as matrix material, can obtain very high temperature resistant ability, can withstand instantaneous temperature of 3000 degrees celsius. The glass steel pipe in recent years in the shipbuilding industry is very popular and special attention, such as ship oil tankers, chemical tankers, offshore platform and ship ballast system, at the request of foreign shipowners in the use of glass steel pipes and fittings, its advantages in addition to the static electricity can guide, there are many advantages. Such as light weight, FRP pipe the same general size is only 35% of the weight of the steel pipe, is resistance to seawater corrosion, general steel and glass pipe manufacturers can promise: 50 years. Its disadvantage is that the pressure can bear the bottom and the modulus of elasticity is low. But it's enough in the ballast system. The GRE tube is better than the GRP tube in tensile strength and pressure resistance, so some people refer to the GRE tube as the high-pressure FRP pipe.

- Q: How to connect glass fiber reinforced plastic sand pipe?

- The overall pressure test shall be carried out with reference to the code for construction and acceptance of water supply and drainage engineering pipes (GB50268-97), with a length of not exceeding 1000m for one section. Double "O" type sealing ring connection can bear the small foundation settlement change, this is the most prominent feature. Docking can be used for ground pipeline installation, can also be used to connect the underground pipeline of individual short, if more construction can meet the requirements of pipeline connection, some information that this connection is a flat end of life, is the use of epoxy resin and glass fiber cloth paste paste, the specific operation method is: first brush the connecting part in the pipeline for a layer of epoxy resin after pasting a layer of glass fiber cloth, flat interface paste length is generally about 500 mm, usually labeled with 5~6 paste layer layer is more solid, each layer of paste paste thickness should not be too large to be a layer of initial setting after a layer of paste. Flange connection line rigid connection, mainly used for connecting glass steel pipe and cast iron pipe, valves and other accessories, often used by glass steel bell and spigot size design, processing special steel bell and spigot connection.

- Q: How long is the service life of glass fiber reinforced plastic pipes?

- Hebei, Qingdao and Beijing have additional production bases and service liaison points. Willing to work with new and old customers to create a beautiful today, Chinese and foreign. The company with integrity development guide thought, company value go production, learning and research Jimo road. The wide customers and cooperation of different geographical identity peer praise richly endowed by nature is a unique, Wuhua Tianbao, day people for the auspicious clouds. The sludge produced by the glass fiber reinforced concrete grille has good sedimentation, which is beneficial to the removal of the suspended substance in the back section. The glass fiber reinforced concrete grille has strong adaptability, can adapt to different water quality range, and has strong endurance to the shock load of water quality and water quantity sudden change. FRP grating treatment efficiency is higher than activated sludge process. The galvanized grating plate has the advantages of advanced structural design, optimum matching of gas and water, and sufficient heat exchange, with the same level in foreign countries and superior output. Galvanized grille plate steel bracket adopts zinc plating treatment, double paint anti-corrosion or electrostatic powder spraying, corrosion resistance is strong, service life over similar products double. The two-way grille ensures the natural delamination of the medium and the impurity, and at the same time, the discharge method is arranged at the bottom of the tank, so that the cleaning is particularly convenient

Send your message to us

Maintenance Free FRP Composite Pipes without Consequent Pollution

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords