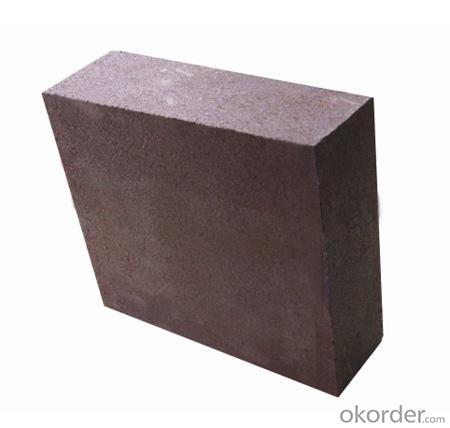

High Temperature Magnesite Chrome Bricks

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 5 Tons m.t.

- Supply Capability:

- 1000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General Information of Magnesia Chrome Brick MGe12

Magnesia chrome bricks MGe12 made from high quality magnesia and chrome concentrate. Due to there are many impurities, the refractory grain are silicate bonded. The magnesia bricks are belong to alkali series refractories and widely used in alkaline atmosphere. The special specification is available under customer’s request.

Characteristics of Magnesia Brick MGe12

Our magnesia bricks MZ87 exhibit the following characteristics:

Strong resistance to slag

Good high temperature properties

Good mechanical strength

Typical Application of Magnesia Brick MGe12

Typical applications of magnesia bricks include ferroalloy furnace, metal mixer, Non-metallurgy industry furnace, calcined lime furnace, regenerator in glass furnace, high temperature kiln.

Technical Data of Magnesia Brick MGe12

Silicate Bonded Magnesia Chrome Brick---MGe-12 | ||||

|

| MGe-12A | MGe-12B | MGe-12C |

Physical Properties: |

|

|

|

|

Cold Crushing Strength | Mpa | 40 | 35 | 30 |

Apparent Porosity | % | 18 | 19 | 21 |

Refractories Under Load(0.2Mpa) | ℃ | 1700 | 1650 | 1530 |

Chemical Analysis: |

|

|

|

|

MgO | % | 65.0 | 60.0 | 55.0 |

Cr2O3 | % | 12.0 | 12.0 | 12.0 |

Note: | ||||

CNBM has success in magnesia bricks due to their cost-effectiveness, excellent thermal shock resistant and high temperature properties. CNBM also has experience in magnesia brick application and would like to assist you in product selection, system design, and installation techniques.

- Q: What are the environmental hazards of magnesia chrome refractory bricks?

- Magnesia chrome brick with MgO and Cr2O3 as the main component of this kind of brick, high refractoriness, high strength, anti alkaline slag corrosion resistance, excellent thermal stability, has certain adaptability in industry wide application of now high temperature acid slag

- Q: How much is magnesium chrome brick a ton?

- The price of bricks in different places is not the same. The average price is about 3500 yuan

- Q: Magnesia chrome brick

- The fine powder compacts after calcination produced by magnesia - chrome ore grinding method, brick with magnesia coarse particles, are effective measures to eliminate the effect of loose. Compared with the common magnesia chrome brick, the magnesia chrome brick made by this method has lower porosity, higher compressive strength, higher softening temperature and higher flexural strength. Compacts with chrome magnesite powder, magnesia chrome brick by synthetic magnesia chrome sand made of high-temperature calcination, slag resistance and high temperature strength are better than other magnesite chrome brick.

- Q: How many kinds of refractory bricks are there?

- Dolomite brick: coating performance, good erosion resistance, but how many bricks f-CaO, yasumizu, it is difficult to transport and storage, production with less.

- Q: Magnesium chrome brick price?

- Magnesia brick factory with strong technology foundation as the basis, has developed more than 40 varieties of products, including building materials, non-ferrous metals, iron and steel and other fields, won the national high-tech products nearly a dozen, four patents, including magnesia spinel brick reached the world advanced levelFrom July 2006 to now won the high-tech enterprises in Liaoning province; National Standardization Management Committee issued the "adopting international standard product certificate" enterprises; in 2009 passed the ISO9001 quality management system certification; the famous brand products of Liaoning Province certificate certificate and certificate management, the reliable guarantee for the quality of products.

- Q: What are the types of magnesia chrome bricks for industrial use?

- 1. burned magnesia chrome bricks 2. magnesia chrome bricks 3. semi bonded magnesia chrome brick and magnesia chrome brick generally is the three

- Q: What is a half combination of magnesia chrome bricks?

- Direct binding for magnesium magnesium rock stone or periclase spinel crystals, silicate phases were isolated in the grain asked. Half combined with thermal shock resistance than magnesia chrome brick direct bonded magnesia chrome brick, and about half combined with the characteristics of magnesia chrome brick, some physical and chemical indicators. I don't understand, I know there is a production of magnesia chrome brick factory technicians understand this, is known as gold refractory material factory.

- Q: With different capacitance magnesia brick brick

- Fused magnesia brick brick has compact structure, high mechanical strength,

- Q: What is the difference between magnesia chrome brick and direct bonded magnesia chrome brick?

- The magnesia chrome bricks are divided into ordinary magnesia chrome bricks, direct bonding magnesia chrome bricks, half bonded magnesia chromite bricks, fused magnesia chrome bricks, fused magnesia semi bonded magnesia bricks, and unburned magnesia chrome bricks

- Q: What are the main raw materials of magnesia chrome bricks?

- At present the most widely used are magnesium aluminum alloy, followed by magnesium manganese alloy and magnesium zinc zirconium alloy. Mainly used in aviation, aerospace, transportation, chemical, rocket and other industrial sectors. In practical metals, it is the lightest metal, and the specific gravity of magnesium is about 2/3 of aluminum and 1/4 of iron. It is the lightest metal in practical metals, high strength and high rigidity.

1. Manufacturer Overview

| Location | Henan, China |

| Year Established | 2003 |

| Annual Output Value | Above US$ 50 Million |

| Main Markets | Taiwan; Germany; Italy; Turkey; France; England; Japan; Thailand; Vietnam; Idonesia; Egypt; Ukraine |

| Company Certifications | ISO 9001:2008;GB/T 19001-2008 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin |

| Export Percentage | 10%-20% |

| No.of Employees in Trade Department | 3 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | Fifty thousand tons per year |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | High; Average |

Send your message to us

High Temperature Magnesite Chrome Bricks

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 5 Tons m.t.

- Supply Capability:

- 1000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords