Magnesite Chrome Brick / Direct Boned Mag Chrome Brick / Fused Rebonded Mag Chrome Brick

- Loading Port:

- Dalian

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 m.t

- Supply Capability:

- 100000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General Information of Magnesite Chrome Brick for Furnace

Burnt magnesia-chrome bricks are made from high quality mag-nesia and chrome concentrate, cr2o3 content can be adjusted accord ing to different requirements. The bricks have good thermal stability and high temperature performance, and are widely used in cement kilns and non-ferrous rnetal metallur-gical furnaces and so on. High temperature burnt directly bonded magnesia-chrome bricks, semi-rebonded magne-sia-chrome bricks and rebonded magnesia-chrome bricks are made from low impurity raw materials. All or part of raw ma-terials are preburnt or electro fused. The best proportioning, high pressure moulding, ultra high temperature and good vol-ume stability. The bricks are widely used in large cement ro-tary kiln, and secondary refining units such as RH, VOD, AOD furnaces, non-ferrous metal met-allurgical furnaces, glass tanks and so on.

Direct-bonded magnesia chrome brick is made of low impurity chrome ore and high purity magnesia and sintered at high temperature over 1700℃.

Semi-rebonded and rebonded magnesia chrome bricks are made partially or fully of synthetic fused clinkers. They are shaped under high pressure and sintered at very high temperature.

Feature of Magnesia Chrome Brick

Good high-temperature performance

High thermal shock resistance

Strong slag resistance

High mechanical strength

Application of Mag Chrome Brick

Cement rotary kiln

Non-ferrous furnace

RH furnace for Iron & Steel

Technical Data of Magnesia Chrome Brick

| MGe-8A | MGe-8B | MGe-8C | MGe-12A | MGe-12B | MGe-12C | MGe-16A | MGe-16B | MGe-16C | MGe-20A | MGe-20B | MGe-20C | ||||

| Physical Properties: | |||||||||||||||

| Cold Crushing Strength | Mpa | 40 | 35 | 30 | 40 | 35 | 30 | 35 | 30 | 25 | 35 | 30 | 25 | ||

| Apparent Porosity | % | 18 | 19 | 21 | 18 | 19 | 21 | 18 | 19 | 22 | 18 | 19 | 22 | ||

| Refractories Under Load(0.2Mpa) | ℃ | 1700 | 1650 | 1530 | 1700 | 1650 | 1530 | 1700 | 1650 | 1550 | 1700 | 1650 | 1550 | ||

| Chemical Analysis | |||||||||||||||

| MgO | % | 70.0 | 65.0 | 60.0 | 65.0 | 60.0 | 55.0 | 55.0 | 50.0 | 45.0 | 50.0 | 45.0 | 40.0 | ||

| Cr2O3 | % | 8.0 | 8.0 | 8.0 | 12.0 | 12.0 | 12.0 | 16.0 | 16.0 | 16.0 | 20.0 | 20.0 | 20.0 | ||

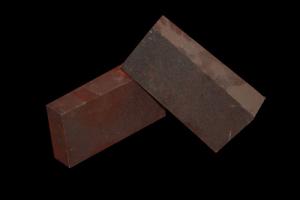

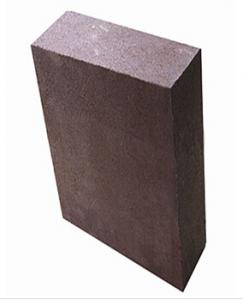

Photo of MagChrome Brick

- Q: What are the differences between magnesium chrome bricks, such as direct bonding, re bonding, semi bonding, CO sintering and chemical bonding? Hope expert advice..

- Direct bonded magnesia chrome brickThe loose effect caused by the expansion of spinel when the oxide of magnesia brick is directly reacted with the oxide of iron can also be used to make magnesia chromite brick with synthetic common sintered material. In addition, there are non burned magnesia chrome bricks, for example, non burned magnesia chrome bricks combined with inorganic magnesium salt solutions. The unfired magnesia chrome brick has the advantages of simple production process, low cost and good thermal stability, but the strength of the high temperature is far less than that of the burnt brick. In the late 50s, a so-called "direct bonding" magnesia chrome brick was developed. The characteristics of this brick raw material is pure, high firing temperature, periclase and spinel phase with high temperature directly, silicate and other low melting point phase for island distribution, therefore, significantly improve the high temperature strength and slag resistance of brick.

- Q: Process for producing magnesia chrome brick

- The fine powder compacts after calcination produced by magnesia - chrome ore grinding method, brick with magnesia coarse particles, are effective measures to eliminate the effect of loose. Compared with the common magnesia chrome brick, the magnesia chrome brick made by this method has lower porosity, higher compressive strength, higher softening temperature and higher flexural strength. Compacts with chrome magnesite powder, magnesia chrome brick by synthetic magnesia chrome sand made of high-temperature calcination, slag resistance and high temperature strength are better than other magnesite chrome brick.In addition, magnesite brick and electric arc furnace melting magnesium chromium material by direct casting (see Figure microstructure, color), fused magnesia chrome brick material produced by the process of melting particles combined with magnesia chrome brick etc..

- Q: Refractory brick, high alumina brick, magnesia chrome brick, magnesia brick, clay brick, which type of high temperature refractory brick?

- High alumina brick clay brick up to 1700 degrees above 1500 degrees -1750 degrees of magnesia brick and magnesia chrome brick 1500-1650 degrees.

- Q: How much is magnesium chrome brick a ton?

- Magnesium chrome bricks according to physical and chemical indicators in order to know the specific price, the production of magnesia chrome brick place a lot

- Q: How many kinds of refractory bricks are there?

- Dolomite brick: coating performance, good erosion resistance, but how many bricks f-CaO, yasumizu, it is difficult to transport and storage, production with less.

- Q: Magnesium chrome brick price?

- Dashiqiao magnesium brick factory of China Building Materials Academy is a joint stock company invested, constructed and managed by China Building Materials Academy.The plant was built in 1992, officially put into operation in 1993, covers an area of 89 thousand square meters, has a long 118 meters, an annual output of 30 thousand tons of high temperature tunnel kiln production line. The group has 1200 employees, 6 senior engineers, more than 20 engineers and technicians, and has strong technical force. Group's total assets of 5.5 million, with an annual output value of 600 million. Profit and tax 65 million yuan.

- Q: What are the types of magnesia chrome bricks for industrial use?

- 1. burned magnesia chrome bricks 2. magnesia chrome bricks 3. semi bonded magnesia chrome brick and magnesia chrome brick generally is the three

- Q: What is a half combination of magnesia chrome bricks?

- Direct binding for magnesium magnesium rock stone or periclase spinel crystals, silicate phases were isolated in the grain asked. Half combined with thermal shock resistance than magnesia chrome brick direct bonded magnesia chrome brick, and about half combined with the characteristics of magnesia chrome brick, some physical and chemical indicators. I don't understand, I know there is a production of magnesia chrome brick factory technicians understand this, is known as gold refractory material factory.

- Q: What is the difference between magnesia chrome brick and direct bonded magnesia chrome brick?

- The magnesium chromium brick with the direct bonded magnesia chrome brick is different: 1 with the purity of magnesia (raw materials) 2: the sintering temperature of common magnesia chrome brick sintering temperature at 1550 DEG ~1600 DEG, direct the magnesium chromium brick sintering temperature is over 1700 DEG C, because of its more than 1700 DEG C, magnesia chrome brick microstructure occurred change, and periclase chromium ore directly combined, so called direct bonded magnesia chrome brick

- Q: What are the main raw materials of magnesia chrome bricks?

- At present the most widely used are magnesium aluminum alloy, followed by magnesium manganese alloy and magnesium zinc zirconium alloy. Mainly used in aviation, aerospace, transportation, chemical, rocket and other industrial sectors. In practical metals, it is the lightest metal, and the specific gravity of magnesium is about 2/3 of aluminum and 1/4 of iron. It is the lightest metal in practical metals, high strength and high rigidity.

Send your message to us

Magnesite Chrome Brick / Direct Boned Mag Chrome Brick / Fused Rebonded Mag Chrome Brick

- Loading Port:

- Dalian

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 m.t

- Supply Capability:

- 100000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches