Magnesia Calcium Brick,Magnesia Dolomite Brick, magnesia dolomite brick, for AOD,VOD,GOR,LF-VD

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

Place of Origin: China

Shape:Brick

Material:Magnesia dolomite

SiO2 Content (%): 1.3

Al2O3 Content (%): 0.5

MgO Content (%): 52.3~80.3

CaO Content (%): 13-42

Refractoriness (Degree): Common (1580°< Refractoriness< 1770°)

CrO Content (%): -

SiC Content (%): -

Model Number: MG-15, 20, 25, 30, 40

Brand Name: CMAX

Fe2O3 Content (%): 0.7

Bulk density (g/cm3): 3.03

Apparent porosity (%): 8

Cold crushing strength(MPa): 55

Refractoriness under Load 0.2MPa (℃): 1700

Supply Ability

Supply Ability:

2000 Ton/Tons per Month

Packaging & Delivery

Packaging Details

in wooden pallets

Port:China port

Product description

Material and Technique

Magnesia dolomite bricks/magnesia calcium bricks for AOD funace use synthetic dolomite sand as raw materials, selecting MgO/ CaO ratio in accordance with different needs, which are produced by high heat sintering and vacuum pressure impregnation pitch or paraffin treatment.

Magnesia dolomite bricks are of alkaline refractory products with a higher MgO content. Generally, MgO content of magnesia dolomite bricks is beyond 35%, then CaO content is more than 40%. In addition, Magnesia dolomite bricks also contain other impurities, such as SiO2, Al2O3, Fe2O3, etc.

Properties

Magnesia dolomite bricks for AOD furnace have good resistance to elevated temperatures and high slag resistance.

Application

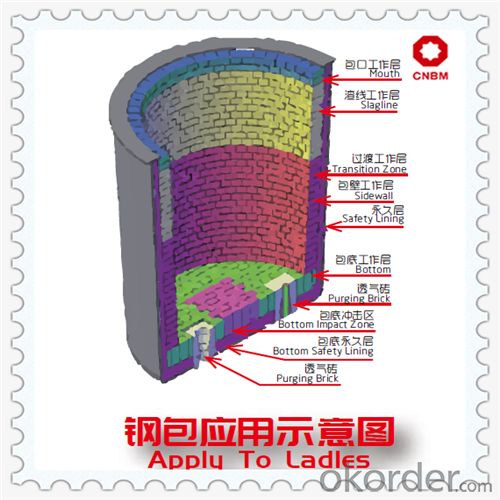

As AOD furnace refractories, magnesia dolomite bricks are increasingly being used as linings for every part of AOD furnace, such as trunnion, tuyere, slag line, wall, bottom and furnace end.

Specifications

Index | MG15 | MG20 | MG25 | MG30 | MG40 |

MgO (%) | 76.3-80.3 | 72.3-76.3 | 66.3-70.3 | 62.3-66.3 | 52.3-56.3 |

CaO (%) | 13-17 | 18-22 | 23-27 | 28-32 | 38-42 |

Al2O3 (%) | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 |

Fe2O3 (%) | 0.7 | 0.7 | 0.7 | 0.7 | 0.7 |

SiO2 (%) | 1.3 | 1.3 | 1.3 | 1.3 | 1.2 |

Bulk density (g/cm3) | 3.03 | 3.03 | 3.03 | 3.03 | 3.0 |

Apparent porosity (%) | 8 | 8 | 8 | 8 | 8 |

Cold Crushing Strength (MPa) | 55 | 55 | 55 | 55 | 55 |

Reheating linear change (%) | -0.35 | -0.61 | |||

Refractoriness under load (℃) | 1700 | 1700 | 1700 | 1700 | 1700 |

Thermal Expansion (%) | |||||

800℃ | 0.8~1.0 | 0.8~1.0 | 0.8~1.0 | 0.8~1.0 | 0.8~1.0 |

1200℃ | 1.35~1.6 | 1.35~1.6 | 1.35~1.6 | 1.35~1.6 | 1.35~1.6 |

1600℃ | 1.8~2.0 | 1.8~2.0 | 1.8~2.0 | 1.8~2.0 | 1.8~2.0 |

Magnesia dolomite bricks supplier

Hitech Material as the magnesia dolomite bricks supplier in China, offers various grades of magnesia dolomite refractory bricks used for various industrial furnaces.

Application

Package

Certification

- Q: What are the differences between magnesium chrome bricks, such as direct bonding, re bonding, semi bonding, CO sintering and chemical bonding? Hope expert advice..

- The process of firing magnesia chrome bricks is roughly the same as that of magnesia bricks. In order to eliminate the brick during firing, due to MgO and Cr2O3, Al2O3

- Q: Process for producing magnesia chrome brick

- The fine powder compacts after calcination produced by magnesia - chrome ore grinding method, brick with magnesia coarse particles, are effective measures to eliminate the effect of loose. Compared with the common magnesia chrome brick, the magnesia chrome brick made by this method has lower porosity, higher compressive strength, higher softening temperature and higher flexural strength. Compacts with chrome magnesite powder, magnesia chrome brick by synthetic magnesia chrome sand made of high-temperature calcination, slag resistance and high temperature strength are better than other magnesite chrome brick.In addition, magnesite brick and electric arc furnace melting magnesium chromium material by direct casting (see Figure microstructure, color), fused magnesia chrome brick material produced by the process of melting particles combined with magnesia chrome brick etc..

- Q: What are the environmental hazards of magnesia chrome refractory bricks?

- Some of the magnesia chrome bricks will be converted into Cr6+ when used, producing K2CrO4 and other toxic and carcinogenic compounds such as Cr3+

- Q: Magnesia chrome brick

- Magnesite brick and electric arc furnace melting magnesium chromium material by direct casting (see Figure microstructure, color), fused magnesia chrome brick material produced by the process of melting particles combined with magnesia chrome brick etc..

- Q: How many kinds of refractory bricks are there?

- Dolomite brick: coating performance, good erosion resistance, but how many bricks f-CaO, yasumizu, it is difficult to transport and storage, production with less.

- Q: Magnesium chrome brick price?

- In the brick factory products are now sold throughout the country and exported to the United States, South Africa, India, Germany, Canada, Ukraine, Japan and other countries, has been recognized and highly refractory materials in the world market.

- Q: What are the types of magnesia chrome bricks for industrial use?

- 1. burned magnesia chrome bricks 2. magnesia chrome bricks 3. semi bonded magnesia chrome brick and magnesia chrome brick generally is the three

- Q: What is a half combination of magnesia chrome bricks?

- Direct binding for magnesium magnesium rock stone or periclase spinel crystals, silicate phases were isolated in the grain asked. Half combined with thermal shock resistance than magnesia chrome brick direct bonded magnesia chrome brick, and about half combined with the characteristics of magnesia chrome brick, some physical and chemical indicators. I don't understand, I know there is a production of magnesia chrome brick factory technicians understand this, is known as gold refractory material factory.

- Q: With different capacitance magnesia brick brick

- Fused magnesia brick brick has compact structure, high mechanical strength,

- Q: What is the difference between magnesia chrome brick and direct bonded magnesia chrome brick?

- The magnesia chrome bricks are divided into ordinary magnesia chrome bricks, direct bonding magnesia chrome bricks, half bonded magnesia chromite bricks, fused magnesia chrome bricks, fused magnesia semi bonded magnesia bricks, and unburned magnesia chrome bricks

Send your message to us

Magnesia Calcium Brick,Magnesia Dolomite Brick, magnesia dolomite brick, for AOD,VOD,GOR,LF-VD

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords