Lynn Manufacturing High Pure Ceramic Fiber Board - Refractory Heat Insulation

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Ceramic Fiber Board for Fireplace 1260C

Product Description

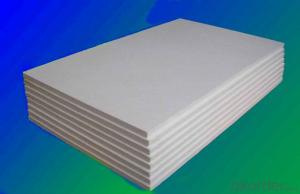

General InformationCMAX refractory ceramic fiber board is made from high pure ceramic fiber, with some inorganic and suitable organic binders. The mixture is vacuum processed into boards or formed shapes that keep good mechanical strength after heating, with characteristics of low thermal conductivity, good stability in high temperature, identical bulk density and thickness, excellent resistance to thermal shock , rigidity and flexural strength, low density.

easy to cut or machined, stable chemical performance, resistance to most of the erosion of the chemicals. When add the organic binders first time, it lost in temperature between 300°C-600°C and become pure white after the binders burned out.

Characteristics:

Asbestos free

Smooth surface, identical bulk density and thickness

Excellent high temperature strength and thermal stability

Low thermal conductivity

Low shrinkage

Low thermal capacity

Resistance to gas flow velocity

Direct contact with the flame

Easy cut and installation.

Features

Low thermal conductivity

Excellent thermal shock resistance

Excellent chemical stability

Even density and thickness

Non standard sizes are available upon request

Application

Back-up lining of high temperature furnaces.

Lining and fire board for Ceramic tunnel kiln , roller kiln , shuttle kiln and other thermal equipment

Back-up and hot-face insulation material for furnaces or aluminum industry

Insulation material for Metallurgy, machinery , chemical, optical, and environmental protection industries

Other Industry insulation material

CERAMIC FIBER BOARD ---STD

Classification Temperature (℃) | 1260 |

Working Temperature (℃ ) | 10 00 |

Color | White |

Bulk Density (kg/m3 ) | 240-300 |

Thermal Conductivity(W/m.k) | |

400℃ | 0.067 |

600 ℃ | 0.094 |

800 ℃ | 0.136 |

1000 ℃ | 0.152 |

1200 ℃ | 0.190 |

1300 ℃ | - |

Thermal Shrinkage 24hrs (%) | 1200℃ |

-3.3 | |

Chemical Composition (%) | |

Al2O3 | 45-47 |

Al2O3+ SiO2 | 97-98.5 |

Note: Technical Data are typical results from test pieces. This information, subject to change, is offered solely for your consideration. Users of our products should make their own tests to determine the suitability of each product for their particular purposes.

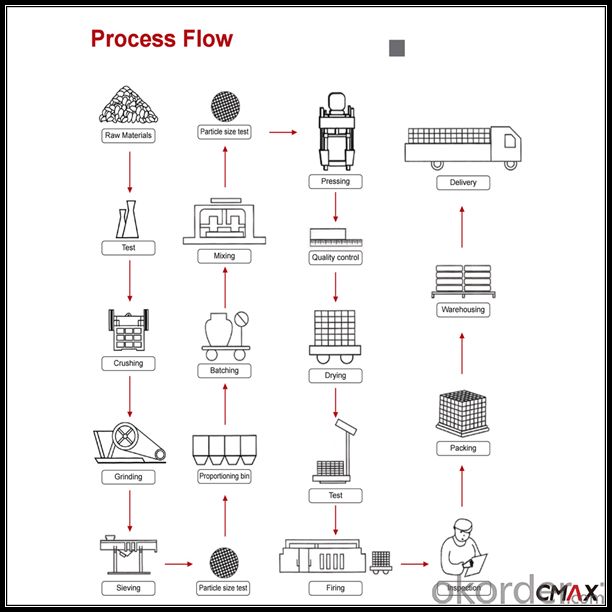

Ceramic Fiber Board Process Flow

Packaging & Shipping

Packaging Details: Wrapped by plastic bag and then put into carton box designed for export.

Delivery Detail: 30 days after order

Our Services

Optimum solution and product supply of refractories for high temperature industries, such as iron&steel, non-ferrous, petrochemical and building materials.

Engineering design, contract and consult for refractories, and civil architecture design.

Research,development, manufacture and sale of superhard materials.

R&D, manufacture and sale of special packing materials for export.

Inspection,supervision and arbitration of refractories.

Consultation and services in refractories information.

Training and cultivation of high-level talents in refractories profession

Company Information

CNBM (China National Building Material) Group is the largest comprehesnsive building materials group in China that in intergrate scientific research,manufacturing and logistics into one entity.the largest building materials and equipment specialists in China. Upon State Council approval, today CNBM owned more than 300 subordinate manufacturing factories and servicing companies. There are 6 fully owned public listed companies and 11 partially owned with substantial shares public listed companies. In many of these fields,CNBM is playing the leading role in the building industry in the country.

FAQ

1. Which products do you have?

We have all kinds of refractory brick, castable, mortar, cement, ceramic fiber products, etc.

Or you could browse our products to choose what you need.

2. Can you give me a brief introduction of the application of your products?

We are mainly specializing in the refractory materials in iron and steel, cement, glass, ceramics, petrochemical, electric power Industry, etc.

3. If I need your offer, what information do you need?

In order to choose suitable products, it will be appreciated to provide us the information, such us specification, technical data, order quantity, products application etc.If any question, please contact us freely.

- Q: What method should be used to measure the thermal conductivity of fiberboard?

- Fiber board thermal conductivity of ceramic fiber board thermal conductivity information is mainly: ceramic fiber board thermal conductivity, thermal conductivity of ceramic fiber board price, thermal conductivity of ceramic fiber board wholesale, thermal conductivity of ceramic fiber board factory, discusses the protection method of hot plate test principle and method of MDF thermal conductivity and its relation with temperature; and analyzed the test error.

- Q: What are the standards for ceramic fiber boards?

- The existing ceramic fiber board has broken through the age of fear of water, and the newly developed hydrophobic ceramic fiber board has the characteristics of normal working under the water environment.

- Q: Ceramic fiber plate and aluminium silicate plate are chosen as lining materials

- Ceramic fiber surface roughness, accurate size, good toughness, can be arbitrarily cut, good insulation effect; ceramic fiber board can be distinguished according to the temperature, heat is widely used in the back lining of industrial furnace and kiln temperature, kiln is an important guarantee for energy saving, high yield and quality factors of A.

- Q: What are the sound-absorbing fiber boards?

- Ordinary materials have sound-absorbing effect, just how much difference. And when it comes to sound-absorbing board, we are only sound-absorbing coefficient of more than 0.3 of the material known as sound-absorbing material.

- Q: What is the difference between ceramic fiber board and nano ceramic fiber board?

- The nano ceramic fiber board through the introduction of nanotechnology, the special production process, product performance has been greatly improved, high strength, low thermal conductivity, good heat insulation performance, energy saving effect is obvious, which improves the safety of the furnace, and in high temperature and high pressure conditions, can also play a good performance the product.

- Q: What are the specifications of the ceramic fiber board?

- Ceramic fiber board density in conventional 300-350Kg/m over 350Kg/m to fand, fand fireproof plate series.

- Q: What are the differences between nano ceramic plate and ceramic fiber board?

- Nano ceramic plate for ceramic fiber with insulating board (felt), it is a functional material with excellent properties of aerogel insulation material and has a heat shielding function, adaptation to adhesive and a variety of inorganic elements in high temperature ceramic fiber as reinforcing material, through a special process preparation.

- Q: What are the uses of ceramic fiber boards?

- Ceramic fiber board is the main use of heat insulation, fire protection, insulation to use, but also with sound absorption, noise reduction, thermal shock resistance and so on. Ceramic fiber board is mainly used in all kinds of furnace lining insulation, kiln wall lining insulation, metallurgical industry furnace fire, aluminum reduction tank, refractory brick backing.

- Q: Is there any difference between ceramic silicon fiber board and ceramic fiber board?

- 1, high compressive strength, long service life; 2, low heat capacity, low thermal conductivity;3, non brittle material, good toughness;4, accurate size, good flatness;5 、 easy to cut and install, easy to construct;6, excellent wind erosion resistance;7 、 continuous production, uniform distribution of fiber, stable performance.

- Q: How much pressure can the ceramic fiber board withstand?

- Ceramic fiber fireproof plate, the density of 350-400Kg/m ceramic fiber board, fand; density above fand 400Kg/m.

Send your message to us

Lynn Manufacturing High Pure Ceramic Fiber Board - Refractory Heat Insulation

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords