LSAW SSAW CARBON STEEL PIPE ASTM API 12’‘

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

Packaging Detail: | Normal exporting packing,in container or bulk vessel or as per clients' request |

Delivery Detail: | 2 months after confimed contract |

Specifications

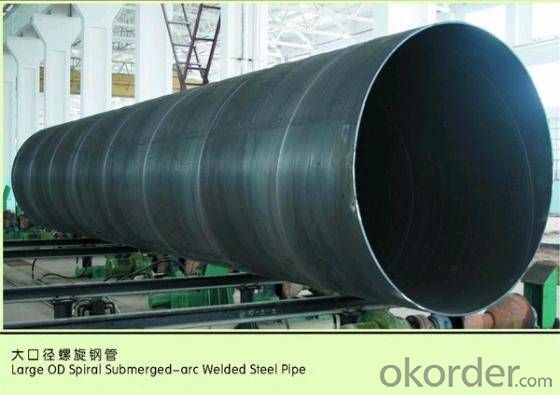

Large Diameter API 5L X70 PSL2 LSAW Steel Pipe

Grade: X42, X46, X50, X52, X60, B, C

OD: 1.5"-28"

WT: SCH10-SCH160

Large Diameter API 5L X70 PSL2 LSAW Steel Pipe

Specifications:

u Standard: API 5L

u Grade: B, C, X42, X46, X50, X52, X56, X60, X65, X70, X80

u OD: 1.5"-28"

u WT: SCH10-SCH160

u Length: 5-12m

u Ends Finish: plain end, bevel end, grooved end

u Surface Treatment: bare, black varnished, oiled finish, red color, anti-corrosion, 3PE, FBE or epoxy coating

u Technique: hot rolled or cold drawn

u Application: api 5l steel pipe for conveying oil, water, gas

u Invoicing: based on theoretical weight or actual weight

u Payment Terms: L/C at sight, T/T or Western Union

u Trade Terms: FOB, CFR, CIF

u Certification: ABS manufacturing assessment, ABS design assessment, API 5CT, API 5L, DNV manufacturer certificate, ISO9001 quality management system certificate, ISO14001 environment management system certificate, GB/T28001 occupational health and safety management system certificate, A1 class manufacturing license of special equipment certificate, CCS, GL, LR, SGS, TüV, PDE

- Q: How are steel pipes used in the construction of wastewater treatment plants?

- Steel pipes are used extensively in the construction of wastewater treatment plants for various purposes. They are used for the transportation of wastewater from one unit to another, as well as for the distribution of treated water to different areas. Steel pipes are also used in the construction of the main water supply and drainage systems within the plants. Additionally, they are utilized for the installation of pumps, valves, and other equipment required for the treatment process. The durability and strength of steel pipes make them an ideal choice for the demanding and corrosive environment of wastewater treatment plants.

- Q: What are the different types of steel pipe joints for underwater applications?

- There are various types of steel pipe joints used for underwater applications, including welded joints, flanged joints, and mechanical joints. Welded joints involve fusing the ends of the pipes together using welding techniques, creating a continuous, strong connection. Flanged joints use flanges, which are flat, circular discs, to connect and secure the pipes together. These joints are commonly used in applications that require frequent disassembly. Mechanical joints, on the other hand, utilize mechanical devices such as couplings or clamps to connect the pipes. These joints provide flexibility and ease of installation and removal.

- Q: Are steel pipes affected by magnetic fields?

- Yes, steel pipes can be affected by magnetic fields. Steel is a ferromagnetic material, which means it is strongly attracted to magnets and can be magnetized. When exposed to a magnetic field, steel pipes can become magnetized, causing them to behave like magnets themselves. This magnetic effect can have several implications. First, if steel pipes are near strong magnetic fields, such as those generated by electrical currents or powerful magnets, they can experience a force that may cause them to move or vibrate. This can be problematic in certain applications, especially if the pipes need to remain stable and secure. Second, the presence of magnetic fields can induce electrical currents in steel pipes. These currents, known as eddy currents, can generate heat and energy losses. In some cases, this can lead to inefficiencies and increased energy consumption in systems that involve steel pipes. Lastly, magnetic fields can also affect the accuracy of magnetic measurement devices used to detect defects or corrosion in steel pipes. The presence of a magnetic field can interfere with the readings, making it more challenging to accurately assess the condition of the pipes. To mitigate these effects, various measures can be taken. For instance, in applications where stability is crucial, steel pipes can be shielded or isolated from strong magnetic fields using non-magnetic materials. Additionally, the impact of eddy currents can be minimized by using pipes with proper insulation or by using magnetic shielding techniques. Overall, while steel pipes are indeed affected by magnetic fields, the extent of the impact depends on factors such as the strength of the magnetic field, the composition of the steel, and the specific application or environment in which the pipes are used.

- Q: What does "spiral welded steel pipe" DN325*10 mean?

- Spiral welded steel pipe with nominal diameter of 325mm and wall thickness of 10mm

- Q: Is there a weld on the outer wall of seamless steel tube?

- Seamless steel pipe, not seamless steel pipe, seamless steel pipe, welded seam, how can it be called seamless pipe?. Tell you a method: measurement of wall thickness, multi test several points, if each point, that is because it is cold drawn pipe, seamless pipe, hot rolling, wall thickness may% by sample.

- Q: How are steel pipes used in the manufacturing of renewable energy systems?

- Steel pipes are extensively used in the manufacturing of renewable energy systems for various purposes. They are commonly used as structural components, providing strength and stability to wind turbines, solar panel supports, and hydroelectric power systems. Steel pipes are also utilized for transporting fluids such as water, steam, or gases in energy generation processes. Furthermore, they are essential in the construction of geothermal energy systems, where they are employed to create underground heat exchangers and piping networks. Overall, steel pipes play a crucial role in the efficient and reliable functioning of renewable energy systems.

- Q: Can steel pipes be used for wastewater treatment facilities?

- Yes, steel pipes can be used for wastewater treatment facilities. Steel pipes are commonly used in wastewater treatment plants due to their durability, resistance to corrosion, and ability to withstand high pressures and temperatures. They are suitable for transporting various types of wastewater, including industrial effluents and sewage, making them an ideal choice for such facilities.

- Q: What are the different sizes available for steel pipes?

- Steel pipes are available in a wide range of sizes, ranging from small diameter pipes typically used for plumbing purposes, to large diameter pipes used in industrial applications. These sizes can vary significantly depending on the specific requirements and intended use of the pipe, but common sizes include 1/2 inch, 3/4 inch, 1 inch, 2 inch, 4 inch, 6 inch, 8 inch, and 10 inch, among others.

- Q: How are steel pipes used in the construction of oil refineries?

- Steel pipes are extensively used in the construction of oil refineries as they are strong, durable, and resistant to corrosion. These pipes are used for various purposes such as transporting crude oil, refined products, and various chemicals within the refinery. They are also utilized in the construction of the refinery's infrastructure, including the fabrication of storage tanks, process equipment, and piping systems that connect different units and sections of the facility. Overall, steel pipes play a crucial role in maintaining the integrity and efficiency of oil refineries.

- Q: What is PE coated steel pipe? Seek explanation

- PE coating on the inner wall of steel pipe steel pipe is covered with a layer of polyethylene plastic polymer, PE, polyethylene (Polyethylene of raised temperature is the abbreviation of resistance English), the scope of application of the general PE pipe water supply pipe to a temperature below 40 DEG C, cannot be used for hot water transmission pipeline.

Send your message to us

LSAW SSAW CARBON STEEL PIPE ASTM API 12’‘

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords