Lithopone Chemical B301

- Loading Port:

- Tianjin Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 24MT m.t.

- Supply Capability:

- 120000MT Per Year m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

The product: Lithopone 28% (B301)

Lithopone 28% (B301) is an organically coated white pigment based on a co-precipitated zinc sulfide / barium sulfate.

Typical Properties of Lithopne 28%:

● Low binder requirement

● Good dispersibility

● Neutral hue

● Low abrasiveness, thanks to low Mohs hardness

Applications of Lithopone 28%:

● Paints and coatings

Suitable for use in matt and semi‑matt powder-coating systems, thanks to its favorable rheological properties and excellent compatibility with coloured pigments.

● Paper

Achieves high dry opacity in the pulp. Its good retention permits use in pigment size preparations. Bimodal particle distribution improves the porosity of the paper.

● Plastics and rubber

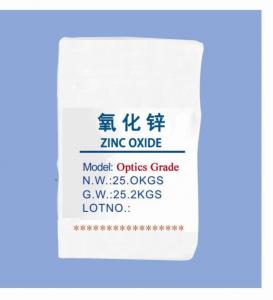

Technical Data of Lithopone 28%:

Project | B301 (28%) |

In terms of total zinc sulfide and barium sulfate the sum of% (m / m) ≥ | 99 |

The total amount of zinc (in zinc sulfide)% m / m) ≥ | 28 |

Zinc Oxide% (m / m) | 0.6 |

105 ℃ Volatile% (m / m) ≤ | 0.3 |

Water soluble% (m / m) ≤ | 0.4 |

Filter material (63μm filter)% (m / m) ≤ | 0.1 |

Color (with standard sample) | Excellent |

Death by degrees to take liquid water | Neutral |

Oil Absorption g/100g | 14 |

Reducing power (with standard sample)% ≥ | 105 |

Opacity (contrast ratio) | Not lower than 5%standerd sample |

Storage of Lithopne 28%:

Keep the product unstacked in dry and closed rooms at normal temperature and air humidity.

To achieve best possible results, we recommend storage under the conditions stated above and use within 12 months from delivery.

- Q: Tattoo pigments into the body later, what will happen, in the first few layers of skin inside

- Tattoo line paint is our ordinary ink with blue ink, black ink, generally with blue ink, into the body will not how, in the second layer of the skin, the general into the skin only 0.1 mm, bold people will pattern deep , Looks obvious, easy to fade

- Q: How much is a kilogram of paint

- Ranging from a few dollars to a few hundred dollars, to see what you want quality

- Q: What is the difference between plant health paint and ordinary paint?

- Blowing the concept of it, plus a little bit of price, environmental protection is certainly better, there are advantages and disadvantages, just say that the benefits do not say bad, really so good not popular, like electric cars, more like TV shopping

- Q: How is paint made today without lead?

- Artists paints are made in much the same way they always have been: by grinding coloured powders (pigments) very finely, and mixing them with a liquid (a medium) that sets, so as to glue the colour to a surface. That's what a paint is. In the past it was done by hand (it was the one of the first jobs an artist's studio assistant would be set to work doing), now it's done by machine. Lead oxides are still used as pigments, mainly in Flake White. Safety regulations banning lead paints only apply to house paints, not artists' paints (at least in the UK), though they may have to be sold in childproof tins. Alternatives to lead include zinc and titanium, which may be mixed to give a white paint that looks similar to Flake White.

- Q: not saying that the dresser is old or anything.....just the best paint to use overall....

- tricky aspect. try searching on search engines like google. it could actually help!

- Q: 60 square meters of the house to use the number of paint and paint

- The coating area of the latex paint depends on the flatness of the substrate and the coating rate of the paint itself. The coating rate is generally marked on the drum, because it is twice the brush, so dividing by 2 is the theoretical brushing area. The surface is more rough on the RBI margin, with putty approved in accordance with the theory of brushing area calculation.

- Q: How does chemical pigments differ from mineral pigments?

- Dye is a color material, but the color of the material is not necessarily a dye.As a dye, must be able to make a certain color attached to the fiber and easy to fall off, discoloration.

- Q: Brush latex paint or stickers good wallpaper?

- From the protective effect, the latex paint and wallpaper are their pros and cons. Latex paint on the putty layer has a direct protective effect, not water resistant putty brush paint after the life will be longer, but the latex paint is still unable to force the grass-roots cracks, cracking more;

- Q: What is the difference between mixed water and clean water in environmental protection?

- Water, mixed water in the home improvement refers to the paint coating. Paint is divided into mixed paint and clear water paint. Mixed water paint is able to cover the original grass-roots paint. Clean paint done finishes, you can see in the end, filling the material qualities, natural texture clearly visible, the formation of the film texture and three-dimensional feel particularly good, the material requirements are relatively high.

- Q: How to stain the sheets, dyeing principle is not the same as the clothes, bed sheets bedding tattoo what dyes, art shops have to sell these dyes

- The principle of printing, of course, with the same fabric, but not the same with the clothes.

1. Manufacturer Overview

| Location | Hebei ,China |

| Year Established | 1958 |

| Annual Output Value | Above US$ 10 Million |

| Main Markets | North America; South America; Eastern Europe; Southeast Asia; Africa; Oceania; Mid East; Eastern Asia; Western Europe; Southern Europ; South Asia |

| Company Certifications | ISO 9001:2000 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin Port |

| Export Percentage | 41%-50% |

| No.of Employees in Trade Department | Above 10 People |

| Language Spoken: | English; Chinese; |

| b) Factory Information | |

| Factory Size: | Above 50,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | Design Service Offered; Buyer Label Offered |

| Product Price Range | High; Average |

Send your message to us

Lithopone Chemical B301

- Loading Port:

- Tianjin Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 24MT m.t.

- Supply Capability:

- 120000MT Per Year m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords