Optics Grade Zinc Oxide For Optics

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 20MT m.t.

- Supply Capability:

- 6000 MT Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Production method Of Zinc Oxide For Optics :

1. It has the good crystal structure, and has the ideal function in the optical material production.

2. It has the anti-radiation function, affects obviously in the color glass Display.

Application Of Zinc Oxide :

It can be used in the optical glass, colored glass, display glass, zinc oxide thin film and photosensitive material production.

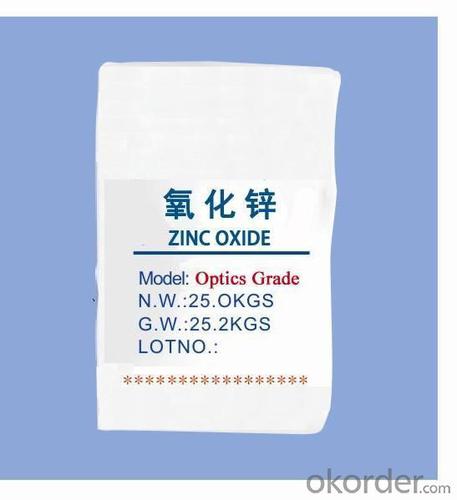

Packing and Storage Of Zinc Oxide For Optics:

This product is packed with plastic-lined and plastic-coated woven bags, 25kg per bag.

This product should be keep from breakage, moisture, pollution and contact with acid.

Product quality standards: GB/T 3185-92

Item | Quality | ||||

91 | 92 | 93 | 94 | 95 | |

Zinc oxide(counted by dried substances )/%≥ | 99.9 | 99.8 | 99.7 | 99.5 | 99 |

Metal ( Zn ) /%≤ | None | None | None | None | None |

Lead oxide( Pb ) /%≤ | 0.001 | 0.005 | 0.037 | 0.05 | 0.08 |

Cupric oxide( Cu ) /%≤ | 0.0001 | 0.0002 | 0.0003 | 0.0004 | 0.0006 |

Manganese oxide ( Mn) /%≤ | 0.0001 | 0.0001 | 0.0001 | 0.0001 | 0.0001 |

Hydrochloric indissoluble substance /%≤ | 0.002 | 0.006 | 0.006 | 0.008 | 0.02 |

Ferrous oxide( Fe) /% ≤ | 0.001 | 0.001 | 0.002 | 0.003 | 0.004 |

Burning decrement /%≤ | 0.1 | 0.15 | 0.18 | 0.2 | 0.3 |

Water dissoluble /%≤ | 0.05 | 0.08 | 0.1 | 0.2 | 0.4 |

105℃volatile substances /%≤ | 0.06 | 0.08 | 0.3 | 0.4 | 0.8 |

Grain size (um) | 20-50nm | 10﹣30 | 10﹣40 | 30-50 | 50-60 |

Color(with standard sample) | white | white | white | white | Yellowish |

Decoloration strength (with standard sample) | 99 | 100 | 100 | 95 | 95 |

- Q: The words on the paint are the first to paint or paint the paint first

- Paint first

- Q: What is the difference between a pigment ink for a printer and an ordinary ink?

- It is filled with dye ink it does not matter

- Q: What are the types of ink used in inkjet printers?

- Thermal transfer ink thermal transfer ink, also known as sublimation ink, thermal transfer ink can not be printed directly on the terminal medium, is to print the ink on the special paper, by printing the paper on the terminal medium, through Heating, in the shortest possible time will be dedicated to the image of the paper transfer to the terminal medium, so you can in such as porcelain, metal, silk, chemical fiber fabrics and other materials to make beautiful patterns, very suitable for personalized development Market needs. The current thermal transfer ink in the desktop printer is mainly used for Epson printers.

- Q: What is a photopolymer?

- At present the main photosensitive materials are: bisphenol A epoxy acrylate, polyurethane acrylate, amino acrylate, dipropylene glycol diacrylate, hydroxypropyl acrylate and so on. Mostly for a variety of acrylate polymers. Used for light-cured coatings and dyes.

- Q: How is the gray out of the paint?

- Black and white, white and more bright, dark and dark. Ask: No! Ask: I tried to ask:! Added: gray, is the so-called dirty color, with a class is not a mixture of color is gray, the more mixed color types, you try? Added: black is in addition to white other than the color of the synthesis, and gray is black plus white added: gray is generally a little bit plus a little black, according to the impact of the environment will be added to the various colors to reconcile. When painting water powder, each tune and a color only draw a few it, so the color change is very important. Add the color of the paint more, the effect is also worse, the lower the purity, the screen will be dirty. Added: too deep, plus plus white ah. The The Ask: no question: should be it!

- Q: What is the difference between leather dyes and ordinary paint?

- There are many kinds of paint pigments, including oil paints, Chinese painting pigments, watercolor paint, gouache pigments, acrylic pigments, resin pigments, etc., including a variety of agents, linseed oil, peach gum, propylene emulsion, alkyd emulsion. And the chemical properties of leather dyes and uses are completely different.

- Q: The effect should be the same as the wallpaper. There is no relevant website. how much is it? thank you all! The The

- Surface porous, pattern or the original color, will affect the amount of paint. The porous surface absorbs the amount of paint, especially the primer. Similarly, some decorative walls, such as pebble walls, ribbed wallpaper and coarse paint, etc., absorb a lot of paint, and may even reach twice the original estimate. Dark surface often need to brush two inner paint to cover the original color. The outer layer of the outer paint at least brush twice, to the Royal wind erosion. Most lacquered pots are marked with an average amount of paint per unit area

- Q: Giraffe paint and bauhinia paint which brand is good

- They belong to the same grade, in the paint industry is second-tier brand.

- Q: how would you get the paint inside the balloon?

- idk how do u

- Q: What are the differences between paint 106 and 806?

- 106, this is the business in order to promote the name and the quality of the same, if you are 806, you will spend more money

1. Manufacturer Overview

| Location | Hebei ,China |

| Year Established | 1958 |

| Annual Output Value | Above US$ 10 Million |

| Main Markets | North America; South America; Eastern Europe; Southeast Asia; Africa; Oceania; Mid East; Eastern Asia; Western Europe; Southern Europ; South Asia |

| Company Certifications | ISO 9001:2000 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin Port |

| Export Percentage | 41%-50% |

| No.of Employees in Trade Department | Above 10 People |

| Language Spoken: | English; Chinese; |

| b) Factory Information | |

| Factory Size: | Above 50,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | Design Service Offered; Buyer Label Offered |

| Product Price Range | High; Average |

Send your message to us

Optics Grade Zinc Oxide For Optics

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 20MT m.t.

- Supply Capability:

- 6000 MT Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords