Corporate Packaging Tape - Light Duty Adhesive Masking Tape

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2500 roll

- Supply Capability:

- 30000000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General purpose of Light Duty Packaging Adhesive Masking Tape

1) good adhesive

2) good flexibility

3) No residual left

4) Different sizes are available

Feature of Light Duty Packaging Adhesive Masking Tape

general purpose masking tape, adhesive tape, paper tape.

1) good adhesion. 2) good flexibility.

-General purpose masking tape is made of crepe paper coated with natural rubber adhesives.

-It is designed for interior paint masking, light-duty packaging, holding, bundling, splicing and packaging.

-Practical for construction, building, home, office or industrial applications.

-Jumbo roll, log roll and cut roll are available.

-The width of jumbo roll is from 980mm - 1250mm

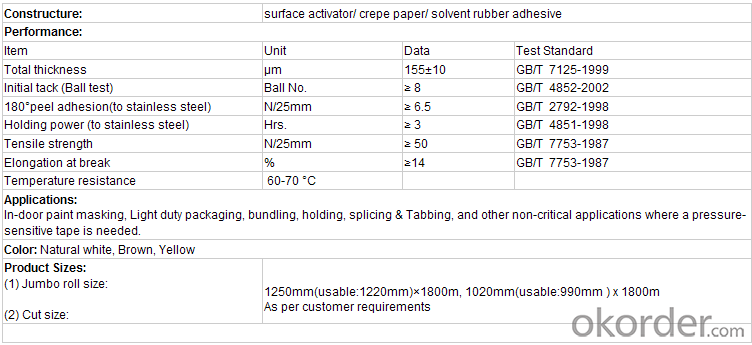

Specifications of Light Duty Packaging Adhesive Masking Tape

Advantages of Light Duty Packaging Adhesive Masking Tape

Different temperature resistance with good adhesion

High tensile strength, good resistance of damage, no residue, eco-friendly

Accept custom design

SGS, ISO, BV, CTI certificates approved

Professional teamwork for orders

No.267 on the 2014 Fortune Global 500

Professional manufacturer with 31 years experiences of adhesive tapes

Special size, color can be made according to customer's requirement.

Our Services

Your inquiry related to our product & price will be replied within 24 hours.

Well-trained & experienced staff can answer all your inquiries in English or other language

Your business relationship wit us will be confidential to any third party

Good after-sale service offered please free feel to contact us for more information

FAQ

Q 1: Do you have any MOQ of Wonder Masking Tape?

A: Yes, according to the size you need.

Q 2: What is the delivery time?

A: Sample time 7 days, 30 days for the mass production.

Q 3: Can we put our logo on the products?

A: Yes, welcome.

Q 4: How should I pay for you if I place order to you?

A: Usually, 30% T/T deposit in advance, 70% balance against the copy of B/L.

- Q: How does packaging tape perform on oily or greasy surfaces?

- Packaging tape typically struggles to perform well on surfaces that are oily or greasy. The adhesive on packaging tape is specifically designed to stick to surfaces that are clean and dry. Therefore, when applied to surfaces that are oily or greasy, the tape may have difficulty sticking securely. The presence of oil or grease acts as a barrier, preventing the adhesive from effectively bonding with the surface. Consequently, there is a greater likelihood of the tape peeling or coming loose. To ensure proper adhesion on surfaces that are oily or greasy, it is advisable to clean and degrease the surface thoroughly before applying packaging tape. Using a degreasing agent or detergent can assist in eliminating the oil or grease, thereby enabling the tape to adhere more effectively. In addition, opting for a high-quality packaging tape that possesses a strong adhesive can also help overcome the challenges posed by oily or greasy surfaces.

- Q: Is packaging tape safe to use on plastic cutting boards?

- Packaging tape is indeed a safe option for plastic cutting boards. Its design enables it to stick to various surfaces, including plastic, without causing any harm or damage. It is commonly utilized for sealing packages and boxes, and does not contain any hazardous chemicals or substances that could jeopardize the plastic cutting board or the food being prepared on it. Nevertheless, it is crucial to acknowledge that utilizing packaging tape on a cutting board is not advised for reasons related to food safety. To avoid potential contamination, it is recommended to employ food-grade materials like food-safe adhesive tape or rubber bands to secure plastic cutting boards.

- Q: Can packaging tape be used for sealing PVC pipes?

- No, packaging tape is not suitable for sealing PVC pipes. It is designed for securing packages and does not provide the necessary strength and durability to effectively seal PVC pipes.

- Q: Is packaging tape safe to use on plastic outdoor furniture?

- Packaging tape is generally considered safe for use on plastic outdoor furniture. It is designed to adhere to different surfaces, including plastic. However, before using packaging tape on your outdoor furniture, it is important to take several factors into account. First and foremost, ensure that the plastic surface is clean and free of dirt or debris. This will enhance the tape's adhesion and prevent any harm to the furniture. Additionally, apply the tape evenly and firmly to avoid any peeling or lifting issues. It is crucial to remember that packaging tape is not specifically created for long-term outdoor use. Although it can be effective in temporarily securing items or protecting surfaces, it may not endure prolonged exposure to severe weather conditions or UV rays. Over time, the tape may deteriorate or leave sticky residue on the plastic furniture. If you require a more durable and weather-resistant solution, it is advisable to utilize specific outdoor adhesives or tapes specifically designed for this purpose. These products are typically made with materials that can withstand outdoor elements and are better suited for long-term use on plastic outdoor furniture.

- Q: Is packaging tape compatible with automatic packaging machines?

- Yes, packaging tape is compatible with automatic packaging machines. Automatic packaging machines are designed to work with various types of packaging materials, including packaging tape. These machines are equipped with mechanisms to dispense and apply packaging tape efficiently and securely to seal packages. Packaging tape is often used in conjunction with automatic packaging machines to streamline the packaging process and ensure that packages are properly sealed and protected during transportation.

- Q: Can packaging tape be used for sealing sports equipment or gear?

- Yes, packaging tape can be used for sealing sports equipment or gear. It provides a strong and secure seal, helping to protect the equipment during transportation or storage. However, it's important to ensure that the tape is applied properly and that it doesn't damage or hinder the functionality of the gear.

- Q: What's the name of the sealing tape specification 40*50y y?

- Is the width 48mm length is 36m Y is smaller than the code.Y is the code, one yard =0.914 meters

- Q: Is packaging tape resistant to UV rays?

- Packaging tape is typically resistant to UV rays, as it is commonly composed of materials such as polypropylene or polyethylene that possess innate UV radiation resistance. Consequently, the tape remains intact and adhesive when exposed to sunlight or other UV sources. Nonetheless, it is crucial to acknowledge that prolonged UV exposure may gradually degrade the tape. For optimal durability, it is advisable to store and employ packaging tape in a cool, dry location, avoiding direct sunlight whenever feasible.

- Q: How do I apply packaging tape evenly?

- To apply packaging tape evenly, start by ensuring that the surface is clean and dry. Hold the tape dispenser at a slight angle, allowing the tape to come out smoothly. Apply gentle pressure while moving the dispenser along the surface, keeping the tape taut and avoiding any wrinkles or folds. It's also helpful to run a finger or a flat object along the tape as you go to ensure it adheres evenly.

- Q: Can packaging tape be used for sealing plastic shoeboxes?

- Yes, packaging tape can be used for sealing plastic shoeboxes. Packaging tape is designed to provide a strong and secure seal on various surfaces, including plastic. It is commonly used for sealing cardboard boxes during shipping and packaging, but it can also be used effectively to seal plastic shoeboxes. The strong adhesive on the packaging tape ensures that the seal remains intact, providing protection to the contents inside the shoeboxes and preventing any dust, dirt, or moisture from entering.

Send your message to us

Corporate Packaging Tape - Light Duty Adhesive Masking Tape

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2500 roll

- Supply Capability:

- 30000000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords