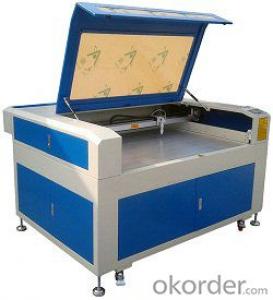

Laser Cutting Machine QL-1121

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Set set

- Supply Capability:

- 150 Sets per Month set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Detailed Product Description

Laser Cutting Machine

High speed & Accuracy

Super quality and competitive price

Perfect after-sales service warranty

Laser Cutting Machine QL-1121

Performance Features

1.Configure higher power laser tube.

2.DSP controlling system, rich functions, can effect engraving on plane, gradient engraving by 360 degree, cutting and drilling holes etc.

3.Owns functions of restoring from power off, continuation on break point.

4.Transmit files directly in CorelDraw, AutoCAD etc.

5.Adopt international linear rail, more precision.

Model |

QL--1121 |

Working area |

160cm*210cm / 63in*83in (L*W) |

Laser power |

130w/150w |

Laser type |

CO2 sealed laser tube,water-cooled |

Cutting speed |

0-50000mm/min (0-1968 inch/min) |

Laser Output |

1-100%software setting |

Resetting positioning accuracy |

≤±0.01mm |

Power supply |

220V/50HZ , 110V/60HZ |

Operating temperature |

0 - 45°C |

Operating humidity |

5 - 95% |

Min. shaping character |

English 1.0 x 1.0mm |

Graphic format supported |

BMP, PLT, DST, DXF, AI |

Software supported |

CorelDraw, PhotoShop, AutoCAD,TAJIMA |

Driving system |

3 phases stepper motor |

Equipment Dimension | 268cm*230cm*112cm 106in*91in*44in |

Packing Dimension | 278cm*240cm*130cm 109in*94in*51in |

Net Weight |

1200kg |

- Q: Can a die push rod be called a thimble?

- This can not be done in cold stamping dies. Plastic and die casting can be called this way

- Q: Die thimble ejector can not be restored, how to solve?

- The mold is out of order. Trim it!

- Q: How about the setting of thimble in plastic mould?

- Without hurting the product, the closer the product, the easier it is to push it out

- Q: The company uses mould heating machine for many years! And the process of production has often thimble top, back not back, also ask that expert pointing one or two!

- It is very common to loosen the thimble a little bit and then clean the mold regularly.

- Q: I'm looking for a browser that can operate regardless of what I'm doing, and the content is always at the top of the computer and won't be switched by other programs! Can also operate other programs next to the browser! I heard the 360 browser has this feature! But I didn't find the settings! Or what software programs allow browsers to be at the top?! Beg! The job needs it!And please tell me how to operate and where to set it!

- Maxthon browser can, but need to first Maxthon official website to register an account, start the browser with the account login, menu selection file locking Maxthon browser on the line.

- Q: A 500mm axis, above steps, 1) car - > mill. Both sides of the thimble hole how processing? If the blank line is not very good condition

- In this way, the two holes must not be on the axle line

- Q: The mold tube thimble can not return to the designated position, the left and right sides have what is going on!

- Your question is a bit general. It may be that the head on the top of the cylinder is larger than the actual one.

- Q: How does the EMX adjust the angle of an irregular flat thimble? (solved temporarily)

- There's a MATE (pairing) in UG. I think PE should have it, too

- Q: Will the injection molding machine test die, thimble white what is going on, what should I do, ask for help?

- This is the debugging problem. Is the size of the clamping force, the debugging of the rod and the electronic ruler in place? Is the release force reasonable?

- Q: Injection white products, mold thimble dirty prints, how to clean?

- I was the wind to blow also ran out of the thimble, thimble said top out the longest limit, take the water that day to wipe the thimble. Not really, then use the mold cleaning agent to spray the thimble gap, and take the pipe blow at the same time!

1. Manufacturer Overview

| Location | Shandong,China |

| Year Established | 2008 |

| Annual Output Value | US$5 Million - US$10 Million |

| Main Markets | 11.11% North America 11.11% South America 11.11% Eastern Europe 11.11% Southeast Asia 11.11% Oceania 11.11% Mid East 11.11% Eastern Asia 11.11% Western Europe |

| Company Certifications | ISO 9001:2000;CE Certificate |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | QINGDAO,TIANJIN,SHANGHAI |

| Export Percentage | 71% - 80% |

| No.of Employees in Trade Department | 6-10 People |

| Language Spoken: | English, Chinese, Russian |

| b) Factory Information | |

| Factory Size: | 5,000-10,000 square meters |

| No. of Production Lines | 10 |

| Contract Manufacturing | OEM Service Offered Design Service Offered |

| Product Price Range | Low and/or Average |

Send your message to us

Laser Cutting Machine QL-1121

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Set set

- Supply Capability:

- 150 Sets per Month set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords