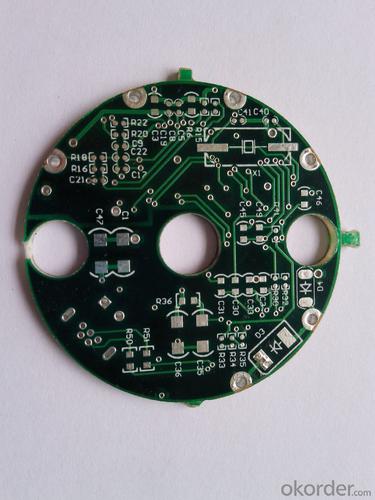

Specifications

PCBA

1.Low cost, Minimum cost for 3 prototypes PCB is $80 only.

2.Short lead time.

3.PCB ROHS compliant.

4.Turkey service

Free Technology Support

PCB Assembly

Military standard assembly

Minimum lead time for assembly is only 3 days

Turnkey service(PCB manufacture, components procurement and assembly)

Prototype building, No Minimum quantity Required

Reliable Parts

Surface mount, through hole, BGA, QFP, QFN …

ROHS compliant and lead-free process

PCB Capability

Material: FR4, High TG FR4, Halogen Free material, Rogers HF material, etc.

Layer counts: 2-28 layers

Finished Copper Thickness: 0.5-5 OZ

Finished Board Thickness: 0.2-6.0mm

Min. Line/Track Width: 4mil

Min. Line/Track Space: 4mil

Min. Contour Tolerance: +/-0.1mm

Min. Finished Diameter of PTH Hole: 0.2mm

Max. Board Thickness/Hole Ratio: 12:1

Min. Solder Mask Bridge: 4mil (Min. SMT Pad Space 8mil)

Min. Legend (Silk screen) Track Width: 5mil

Min. Legend (Silk screen) Height: 30mil

Min. drilling slot size: 0.6mm

Solder mask color: green, black, blue, white, yellow, purple, and matt, etc.

Solder mask hardness: 6H

Legend/Silk screen Color: white, yellow, black, etc.

Surface Treatment: HAL, Lead Free HAL, Immersion gold, OSP, Immersion tin, Immersion silver, etc.

Other Technology: Gold finger, peelable mask, Non-across blind/buried vias, characteristic impedance control, Rigid-flex board etc.

Reliability Test: flying probe test/fixture test, impedance test, solderability test, thermal shock test, hole resistance test, and micro metallographic section analysis, etc.

Wrap and twist: ≤0

Flammability: 94V-0

4. Professional engineering staff to provide technical support.

5.OEM and ODM service are welcome.