Specifications

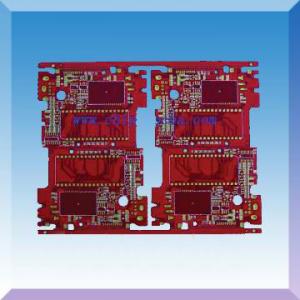

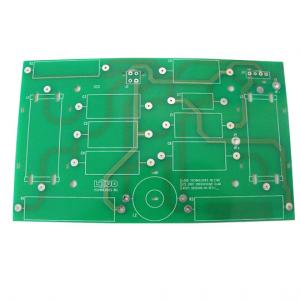

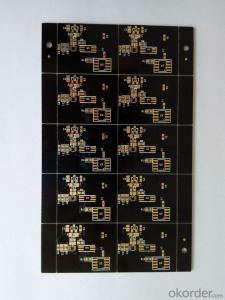

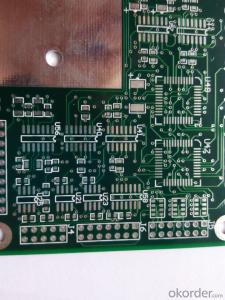

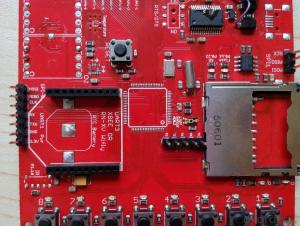

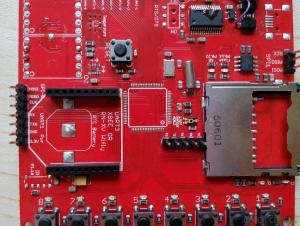

PCB layout ,PCB PCBA and Circuit assembly

1.Competitive price

2. On time delivery

3.NO MOQ

4. Turnkey service

Free Technology Support

PCBA and PCBA Assembly, Suitable for Electronic Products

PCB service:

customized in controller with UL

1. OEM and ODM services are welcome

2. Approval: ISO9001:2008 UL, 16949, RoHS,

3. Quotation in 2 working days

4. Complicated boards and components are also available

8. Adopted the advanced production equipments and testing instruments,

9.High layers PCB manufacturing, up to 36 layers.

10 Low costs, Minimum cost for 3 prototype boards is only $84!!!

11. Fast service, minimum lead time for bare PCB is only 2 days

Leadsintec specializes in producing the various electronic products based on your customized designs and do pcba, pcb assembly for all kinds of small ,medium Volume electronic products

PCB Assembly

Military standard assembly

Minimum lead time for assembly is only 3 days

Turnkey service(PCB manufacture, components procurement and assembly)

Prototype building, No Minimum quantity Required

Reliable Parts

Surface mount, through hole, BGA, QFP, QFN …

ROHS compliant and lead-free process

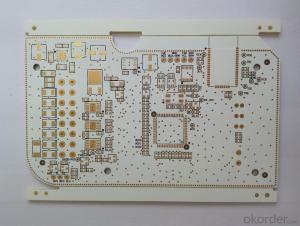

PCB Capability

Material: FR4, High TG FR4, Halogen Free material, Rogers HF material, etc.

Layer counts: 2-28 layers

Finished Copper Thickness: 0.5-5 OZ

Finished Board Thickness: 0.2-6.0mm

Min. Line/Track Width: 4mil

Min. Line/Track Space: 4mil

Min. Contour Tolerance: +/-0.1mm

Min. Finished Diameter of PTH Hole: 0.2mm

Max. Board Thickness/Hole Ratio: 12:1

Min. Solder Mask Bridge: 4mil (Min. SMT Pad Space 8mil)

Min. Legend (Silk screen) Track Width: 5mil

Min. Legend (Silk screen) Height: 30mil

Min. drilling slot size: 0.6mm

Solder mask color: green, black, blue, white, yellow, purple, and matt, etc.

Solder mask hardness: 6H

Legend/Silk screen Color: white, yellow, black, etc.

Surface Treatment: HAL, Lead Free HAL, Immersion gold, OSP, Immersion tin, Immersion silver, etc.

Other Technology: Gold finger, peelable mask, Non-across blind/buried vias, characteristic impedance control, Rigid-flex board etc.

Reliability Test: flying probe test/fixture test, impedance test, solderability test, thermal shock test, hole resistance test, and micro metallographic section analysis, etc.

Wrap and twist: ≤0

Flammability: 94V-0

4. Professional engineering staff to provide technical support.

5.OEM and ODM service are welcome.