Label Sleeving Machine for Packaging Industry

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 unit

- Supply Capability:

- 50 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Label Sleeving Machine for Packaging Industry

1. Product Description:

Sleeve labeling machine applies to food & beverage industries as fruit juice, tea, drink, dairy product spure water consiments,beer and sports drink etc. This bottle labeling machine is suitable for various kinds of bottle types:round bottlle,square bottle,flat bottle etc. Sleeve labeling machine for round bottle not only has a highly precise position for casting label,but also withstand the perfect shape of the bottle after shrinkage.

2. Product Features:

Adjustable cutter head:unquely cyclotron cut-off,double sided cutting edge with a long service life.

Single postioning center guide pillar:a more stable for label delivery. Synchronous bottle divider:a more stable transmission for bottle.

Bottom set of label brush:a more precision for casting label.

3. Product Parameters:

Model | TB-S150 sleeve label shrinking machine |

Capacity | 150bottles/min |

Main Material | SUS304 |

Diameter of Bottle | 28-150mm |

Height of Bottle | 30-280mm |

Lable Material | PVC,PET,OPS |

Applicable Label Thickness | 0.027-0.13mm |

Applicable Label Length | 30-250mm |

Transparent Label Length | ≥5mm |

Applicable Internal Diameter of Tube | 5-10 adjust free |

Voltage | 380V,50/60HZ,3PH |

Power | 1.5KW-2KW |

Machine Dimension | 2100mm*850mm*2000mm |

Weight | 800KG |

4. FAQ:

Q1: What is your delivery time?

A: Generally, the delivery time is 45-60 days after receive the deposit, big production line may take more time.

Q2: What is the payment term?

A: We accept both T/T and L/C. Most customers pay by T/T.

Q3: What kind of after-sevices do you provide?

A: If it is not big problem, we can solve it by emails, phone etc. If it can’t work, our engineers can go to overseas to install and adjust the machine and solve the problems.

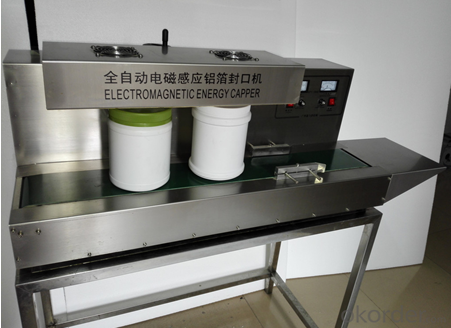

5. Product Pictures:

- Q: As a mechanical component inspector, how do you improve the quality of your product?

- As a mechanical inspector, your job is to inspect the parts. You can't directly improve the quality of the product. You can't process the partsYou can control the quality of indirect suppliers or processors of products, so as to enhance the quality of the products.So you have to adhere to the requirements of national standard drawings or to suppliers or processors, so that the parts can meet the requirements of the drawings,

- Q: The true size of a mechanical part is based on what is on the drawing

- The size of the machine parts shall be in accordance with the size of the drawing as specified on the drawings, and be sure to differ from the marked sizes on the package, especially the irregular parts.

- Q: How is the vacuum packing machine assembled? How many parts?

- Guarantee the quality and life of the whole machine. There are not many parts for vacuum packaging machines.

- Q: Single vacuum packaging machine accessories, vacuum schedule, where to sell?

- Hello, I Division specializing in the production of vacuum packaging machine, vacuum packaging machine accessories, good quality and low price

- Q: After the powder metallurgy parts are machined, how to prevent rust?

- 2, improve the way: Immersion replacement type rust preventive oil, in fact, the base oil or kerosene based, but added a corrosion inhibitor, can improve rust prevention period, about 6-12 months.

- Q: What is the definition of machining process specification?

- The machining process is the process of manufacturing or processing parts or parts, using the method of machining

- Q: What are the main parts of small vacuum machines?

- Hot pressing device and printing deviceThe device is installed in the vacuum chamber, there are usually two groups, a group of single room tipping activities arranged on the lower part of the vacuum chamber and double chamber reciprocating movable part is arranged on the upper part of the vacuum chamber, active device mainly consists of the following parts, heat sealing chamber is fixed on the upper vacuum box room two, head guide column and a spring reset device, hot press frame seat two head guide sleeve is sheathed on the guide pillar, heat sealing between the gas chamber and hot box frame seat is provided with a heat sealing chamber (also known as atmospheric vacuum chamber, said heat sealing chamber for small room heat) sealed air chamber is provided with plastic pipes, two head with a pinch clamp, rubber adhesive processing water is also useful a bicycle or a manpower vehicle tyre, the middle has a gas nozzle, hot pressing frame body with epoxy boards fixed pressing frame seat, two head belt rolling shaft, the winding shaft roll of Ni Cr alloy belt Tight positioning, covered with heat sealing cloth. The fixed part device mainly printing tape and tape box printing, printing glue used in silicone rubber processing, a plane with twill or straight lines, the other side is provided with a round or square hole, the silicon rubber used for processing of words or characters embedded in the park, in the seal and printed on the concave transparent production date. If need is needed in the color printing, printer ribbon. Small treasure vacuum machine

- Q: A workshop to machine parts, 5 boxed 80, according to this calculation, there are 340 parts, 20 boxes can be fully loaded?

- 5 boxed with 8020 boxes are 4 times as many as 5 boxesIn other words, the 4 5 boxes are 20 boxes80 x 4=320So I can't finish it

- Q: Gearbox mechanical parts, mechanical and electrical products?

- Such as threaded parts, keys, pins, rolling bearings and so on. The gear reducer is designed according to different speed reduction systems

- Q: What assembly does the vacuum packer require?

- Vacuum chamber, etc.. Qingdao AI Xun vacuum packaging machine using high quality parts and components, to ensure the quality and life of the whole machine.

Send your message to us

Label Sleeving Machine for Packaging Industry

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 unit

- Supply Capability:

- 50 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot Searches

Related keywords