Case Packer Machine for Packaging Industry

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 unit

- Supply Capability:

- 50 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Case Packer Machine for Packaging Industry

1. Product Description:

Automatic machine for packing product into cartons with a gravity system with moving supports fitted on the in feeding lines.The vertical up-down movement of the cartons which takes place on the loading conveyor is synchronized with the introduction of the bottles and powered by belts. It is a special ideal for plastic products.

2. Product Features:

Faster return on investment.

High-quality and advanced device configuration, use the international generic accessories.

Reliable main drive gear and synchronous bottle blocking, bottle grabbing and bottle guiding system.

Reliable bottle input, bottle counseling, synchronous bottle transporting, sub-bottle system.

Expand production, reduce material waste and improve yield.

Equipment with flexible application and easy to operate.

3. Product Parameters:

Model | ZX15 |

Capacity(CPM ) | 15 CPM |

Application | water, milk, seasoning etc. |

Bottle material | PET, metal |

Bottle shape | around, square, oval |

Bottle size(mm) | Ø50~85mm |

Equipment dimension | 1400×860×1870 (L x W x H, mm) |

Power consumption | 0.75Kw |

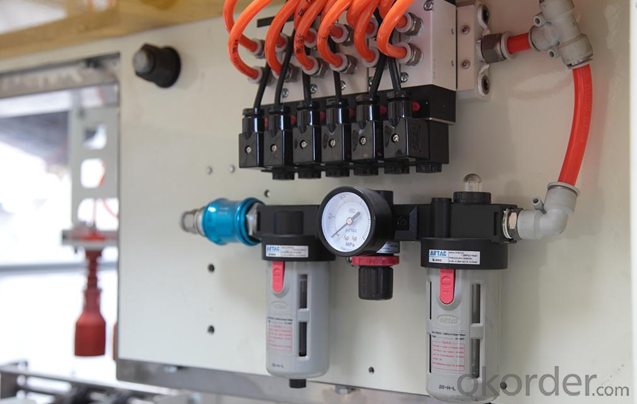

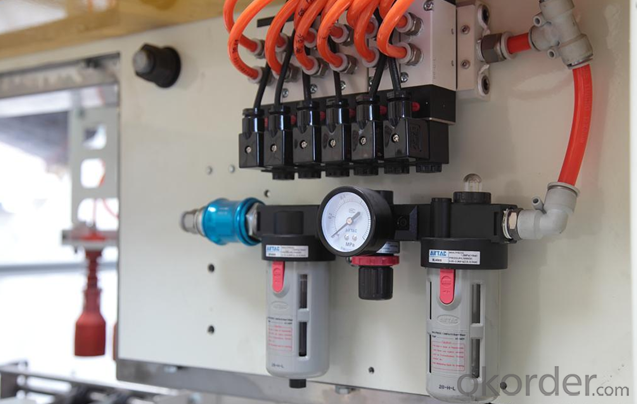

compressed air | (a)pressure: 0.6MPa |

Main Power supply | 3P AC380V 50/60Hz |

Auxiliary power supply | AC220V; DC24V |

Equipment weight | 0.5T |

Equipment noise level | ≤85 dB(A) |

4. FAQ:

Q1: What is your delivery time?

A: Generally, the delivery time is 45-60 days after receive the deposit, big production line may take more time.

Q2: What is the payment term?

A: We accept both T/T and L/C. Most customers pay by T/T.

Q3: What kind of after-sevices do you provide?

A: If it is not big problem, we can solve it by emails, phone etc. If it can’t work, our engineers can go to overseas to install and adjust the machine and solve the problems.

5. Product Pictures:

- Q: What kind of material is better for food packing box?

- Breaker shell, switch, motor, fan shell instrument machinery parts, currency-counting machine parts, electric irons, electromagnetic stove oven accessories; automobile industry in the flow control valve, carburetor cover, window controller, pedal transmission, switchboard cover; mechanical industrial gear, vane, pulley, pump parts, in addition to a wheelchair car body and wheels, lamp shell, lighting device shell, drainage pipe joints, zipper, watch parts, spray parts.

- Q: The original card decocting machine liquid packaging regulation failure, how much liquid packaging do not control, do not know which part of a problem, please master answer, thank you.

- If the liquid is not automatically turn off the power, bet, please check the copper into medicine bag (liquid level probe) soiling, connecting wire level probe is loose behind.

- Q: The true size of a mechanical part is based on what is on the drawing

- The most accurate size is dimensioning! You can't draw correctly, but as long as the marking is correct, the processing is in accordance with the dimensioning!

- Q: Single vacuum packaging machine accessories, vacuum schedule, where to sell?

- Vacuum packaging machine parts, it is best to buy from the original manufacturers, because many vacuum packaging machine, although the main technology is similar, but there will be many differences in detail, size will vary

- Q: After the powder metallurgy parts are machined, how to prevent rust?

- 1, the traditional method: soak kerosene can be short-term rust prevention, but do not expect long-term rust prevention or transportation process rust prevention, rust prevention period is generally in 1-3 months or so.

- Q: How to package machined parts?

- If it's not rusted, clean it and wrap it in a bubble bag. Place it in a cardboard box or wooden case

- Q: What are the main parts of small vacuum machines?

- Aluminum Alloy ordinary aluminum alloy and magnesium alloy, the acid and alkali resistance, corrosion resistance, but the cost is higher, Aluminum Alloy vacuum chamber through a milling processing, the sealing surface and sealing groove is very smooth, the vacuum chamber has good sealing performance. The commonly used stainless steel plate thickness is 2-4MM, thickness of vacuum compression of easy deformation caused by weld cracking, leakage of vacuum chamber, in addition, the general on stainless steel vacuum chamber is provided with a seal groove around the plane, because of the effect of processing, the sealing groove is less smooth, vacuum sealing performance is reduced accordingly. Therefore, some models of vacuum chamber with Aluminum Alloy casting after milling under vacuum sealing groove, chamber adopts thick stainless steel plate processing into plate type, the director, make it short. When purchasing, packaging, and other solid particles relatively dry and non corrosive materials, can be used Aluminum Alloy material, and packaging with soup, salt, acid composition of higher material, can use stainless steel or aluminum magnesium alloy material. The sealing ring is generally made of silicone rubber, black rubber, a few low-grade products using foam rubber, silicone rubber, high temperature resistance, corrosion resistance, good sealing performance, long service life, the foaming rubber sealing is poor, easy to fall off, and short service life. Small treasure vacuum machine

- Q: A workshop to machine parts, 5 boxed 80, according to this calculation, there are 340 parts, 20 boxes can be fully loaded?

- 80 / 5=16 (a);340 / 16=21.25 (box) = 22 (box), 20 (box);Answer: 20 boxes can not be fully loaded

- Q: What assembly does the vacuum packer require?

- The core component is the vacuum pump, and then the control system, the mechanical framework

- Q: Air conditioning installed in the outer machine packaging, found a small part, please master to help see what is this?

- Maybe the workers were not caught in the right place and they fell off during the transportationAfter installation, the blade is unbalanced, the sound of the outdoor fan will increase, and the long time use will also affect the durability of the outdoor fan motor

Send your message to us

Case Packer Machine for Packaging Industry

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 unit

- Supply Capability:

- 50 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot Searches

Related keywords