KXT(S) Raw Meal Dosing and Control Syatem

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 100 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

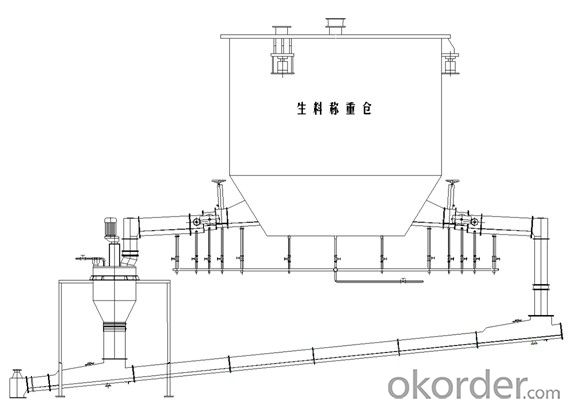

KXT(S) DOSING SYSTEM apply to raw meal dosing feeding and measurement in NSP cement kiln feeding, characterized with stable feeding, accurate dosing, rapid adjusting, zero self correcting, automatic calibration on-line etc, which is in set with the raw meal dosing feeding in 1000-5000t/d NSP cement product line.

1. Composition

This system consist of BD weight calibrate box, WG flow-stabilizing feeder, KL(S) flow meter and control system.

Weight calibrate box can demarcate the flowmeter online, dominate the material level in the box.

Regard as the pre-feeding devise, WG flow-stabilizing feeder can adjust the feeding quantity as discretion, together with the KL(S) flow meter constitute the closed loop control system. The WG flow-stabilizing feeder can feed the material according the given flux demand. The feeder include two apolegamy form , flow-stabilizing impeller and flux control valve. You can choose the apolegamy form thereinto according the different feeding quantity and material speciality. This series mainly apply as Mass-flow powdery material dosing preceding stage feeding equipment.

Control system will get the instantaneous flow after calculate the collected signal, and show the instantaneous flow and progressive volume. At the same time, the system will adjust the WG flow-stabilizing feeder base on the setting value.

2. The main technical characteristics of KXT(S) system

(1) measuring accuracy: out match 0.5%

(2) control accuracy: ±1.0%

(3)measuring range: 10~550t/h (raw material) arbitrarily selected.

(4)Suitable material: raw material, cement or other powdery and granular material.

(5)environment: temperature -20℃~60℃, relative humidity, ≤95%.

(6)Moisture of material: ≤1.5%

3.KXT(S) control system

Control system take the responsibility for accomplishing several task like signal collection, situation estimation, error correction, operation management, data display, system regulation, system communication etc.

Specification

Application scope | Cement raw material, cement, and other powder and granular materials | |||||

Model | KXT-Ⅰ | KXT-Ⅱ | KXT-Ⅲ | KXT-Ⅳ | KXT-Ⅴ | KXT-Ⅵ |

Range(m3/h) | 10~100 | 20~200 | 30~300 | 40~400 | 60~600 | 80~800 |

- Q: What is the proof of working in mechanical design?

- The spatial imagination is good (the drawing is stronger), the logical mind is better (the brain needs to be able to simulate some movement, find out the insufficient); To be able to eat bitterness, to work overtime is a must, don't try to be fat, no more than two or three years of accumulation, nothing will be done, you will not be able to learn to be active.

- Q: What are the potential defects of the automated material handling system?

- Automatic material handling system is to point to a series of related equipment and device, used in a process or a logical action system, coordination, reasonably to control the movement, storage, or material. Be able to carry out the material handling system and the design and arrangement of the container. Positioning of enterprise material handling system is a complicated problem, due to the imbalance between eastern and western regions in economic development in our country, determines the diversity of enterprise material handling system, both reflect the material handling in today's world of advanced science and technology level, by unmanned automatic handling car, automatic solid warehouse, automated conveyor etc of unmanned conveying system, there are still is in the middle of the last century the raw material handling conveyor line, but no matter what level, one thing is common, namely the material handling system and enterprise economic conditions, the level of product quality, Labour, match the market competitiveness of products and so on situation, that is to say, no one of the best material handling system,

- Q: Talk about how to cut the cost of moving materials.

- There is limited room for human efficiency.I hope my answer will help you

- Q: What is the rational and scientific classification of logistics facilities and equipment

- Facilities: like warehouses, roads, public parking lots and so on. Equipment: vehicles, pallets, forklifts, RF scanners, GPS locators, and so on. Large and long-term use and investment, not easy to move and sell are facilities.

- Q: The material needs to be transported, it is easy to produce dust.

- Hello! There are many successful users in the coal-mining plant, such as shenhua, jun, Venus, and extended oil. Before choosing the right device, you need to specify two things: Objective conditions: the operating conditions of the factory, the layout of the workshop space, the material situation and the capability requirements, which conveyance equipment is currently used.

- Q: The wear-resisting parts in the broken machine are mainly the direct contact with the material

- There are many different types of crusher and different performance. For example: the jaw is broken, the hammer is broken, the fight is broken, the cone is broken... It is. Wear-resisting material is different also, also need according to the material hardness, strength of the material that is broken, the choice is ok. Material: white iron, alloy white iron (high chromium cast iron), high manganese steel, alloy steel (high, medium, low carbon and alloy)... It is. Prices are different because of different materials. Otherwise "overqualified person" not to calculate, "small material big use" not only use not, also do not calculate.

- Q: Why should we emphasize unitization and standardization in material handling

- Unitization is the application of scale thought to different materials. We can simplify the links, save the cost, and realize the overall optimization. To facilitate the mechanization of loading and unloading, reduce the labor intensity and improve the efficiency of the work. Reduce the damage caused by the transformation and improve the quality of logistics.

- Q: What is the material handling and handling equipment?

- . Highway transportation equipment Heavy tractor semi-trailer | van | | equipment | special transportation vehicle 9. Warehouse peripheral devices cllimbing trolley | slide machine loading and unloading platform | | | industrial door platform loading and unloading of rain loose 10. | | tray container unit equipment container bags | container net | slide 11. Forklift handling vehicle | electric flat car | | tractor attachments of ft | forklift parts 12. Manual handling equipment Hydraulic pallet truck cart hydraulic pallet stacker | | | lever type hydraulic lifting flat wagon | push car 13. Automatic sorting system, automatic sorting machine | | automatic sorting conveyor system automatic control systems and equipment

- Q: Urgent, please go to logistics expert, the question about the warehouse

- Can put the goods of a few higher. Our company is such a place, a lot more than before, and also not easy be affected with damp be affected with damp. Totally can use this way.

- Q: What is the carrying equipment of the container cargo

- The dragon door crane, the container head crane, the empty box can use the forklift truck, the car crane can be very difficult to lift when the zero time

Send your message to us

KXT(S) Raw Meal Dosing and Control Syatem

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 100 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches