KS80 Shotcrete Robot

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Machine item: KS80 shotcrete spraying machine + KP25 concrete pump

Application: railway tunnel, road tunnel, subway, mining roadway, side slope, water conservancy and hydropower tunnel

Feature:

a) Hydraulic unfold working boom system includes six free working position, rotary of big arm, up and down of big arm, three unfolding small arm, rotary for spraying nozzle, swaying of nozzle, spraying nozzle brushing. That makes shotcrete machine more suitable for multi-layer excavation in tunnel condition.

b) Diesel drive system provides force to machine’s traveling or arm’s activity. Electrohydraulic power group provides power for spraying work.

c) Crawler chassis, equipped with two unfolding hydraulic outrigger leg to maintain the level of machine when it climbs slope.

d) Wireless remote control for unfolding arms working.

e) Mechanic arm dimension(traveling condition) L*W*H 3.2*1.6*2.5 m, 3 meters for minimum working radius in tunnel.

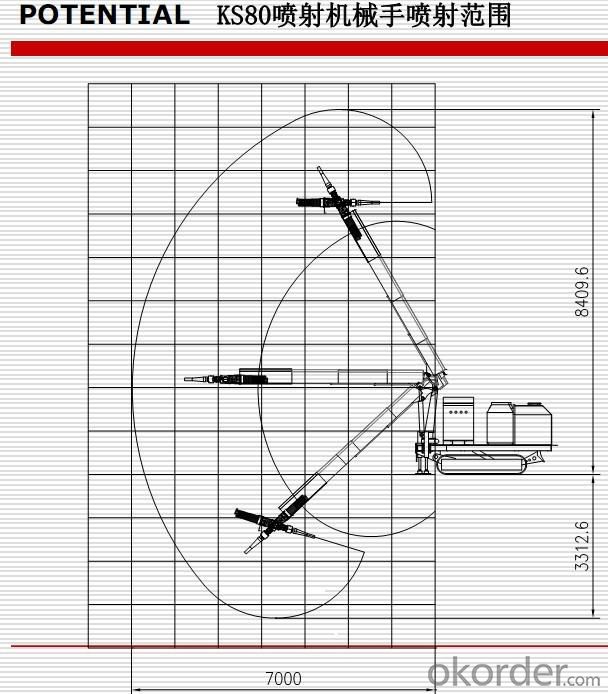

f) Spraying range(Includes one meter spraying distance), approximately 8.5 meters for max height, 14 meters for max width working site.

Technical Parameters

Number | Performance | Parameter | |

KS80 shotcrete machine | |||

1 | Whole unit | Traveling speed (low speed/high speed) (km/h) | 2.2/3.5 |

Slope climbing capability ° | 30 | ||

Ground clearance(mm) | 200 | ||

Transportation dimension(L*W*H) (mm) | 3400*1600*2450 | ||

Weight (kg) | 5000 | ||

2 | Engine | Rated power output(2200 rpm)(kw) | 33 |

3 | Spraying boom | Number of boom | 4 section |

Nozzle rotary angle ° | 360 | ||

Nozzle swaying angle ° | 240 | ||

4 | Accelerate agent | Flowrate(L/h) | 120-600 |

Working pressure (bar) | 10 | ||

volume (L) | 250 | ||

KP25 concrete pump | |||

No | Performance | Parameter | |

1 | Pump | Theoretical Concrete pump capacity(m3/h) | 25 |

2 | Max theoretical output pressure(MPa) | 9.8 | |

3 | Max horizontal transportation distance | 450 | |

4 | Max upright transportation distance | 160 | |

5 | Max aggregate diameter(mm) | 16 | |

6 | Height for loading aggregate(mm) | 1200 | |

7 | Spraying nozzle diameter (mm) | ¢80 | |

8 | Motor | Power output (kw) | 45 |

9 | Whole unit | Dimension(L*W*H)(mm) | 3800*1500*1600 |

10 | Concrete pump self weight(kg) | 2150 | |

- Q: What kind of machinery does the concrete wet spray machine belong to?

- Engineering machinery is an important part of China's equipment industry.

- Q: What should you pay attention to when spraying concrete with a wet spray machine for tunnel works?

- The purpose of this is to make the steel frame and the tunnel rock and concrete to form a whole, common force.

- Q: Are there any differences between concrete dry and wet spray?

- Dry spray: dry spray is the aggregate, cement and quick-setting agent according to a certain proportion of dry mixing evenly, and then into the jet, with compressed air to dry aggregate in the hose was suspended in the state pressure to the gun,

- Q: What is the use of concrete wet spray machine

- 4, wet spray, because the water-cement ratio is easy to control, high degree of concrete hydration, it can greatly improve the quality of shotcrete, improve the homogeneity of concrete.

- Q: What is concrete concrete and net spray concrete?

- The concrete is for reinforced concrete, prestressed concrete and so on.Net spray concrete is arranged on the surface of the steel mesh shotcrete.

- Q: What is the difference between concrete wet spray machine and dry spray machine?

- Wet spraying machine is a vegetation greening machinery and equipment, mainly used for highway (railway) slope greening, slope protection, mountain governance, mine green, desertification, landfill and other projects.

- Q: What is the difference between pouring concrete and shotcrete?

- 2, when the site of the day and night the average temperature of 3d below 5C or the minimum temperature below -3C, the winter construction should be handled, the concrete into the mold temperature should not be less than 5C.

- Q: What is the difference between artificial wet spray concrete and mechanical wet spray concrete?

- A higher degree; artificial spray can not reach the site where the collapse is occurring, mechanical jet just deal with such dangerous situations, give full play to the advantages of spray

- Q: What is the working principle of concrete wet spray machine?

- This type of wet spray machine is generally bulky, but the transport distance is long.

- Q: What is the difference between dry spray and wet spray?

- All kinds of materials (non-water) in accordance with the design requirements for dry mixing and mixing of loose concrete directly fed (through

Send your message to us

KS80 Shotcrete Robot

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords