JXP-180 Automatic liner Bottle Rinser

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 30 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1、Product Details:

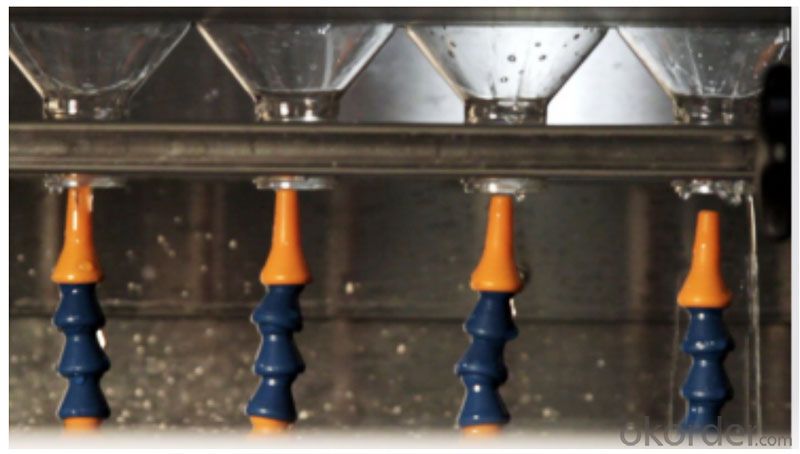

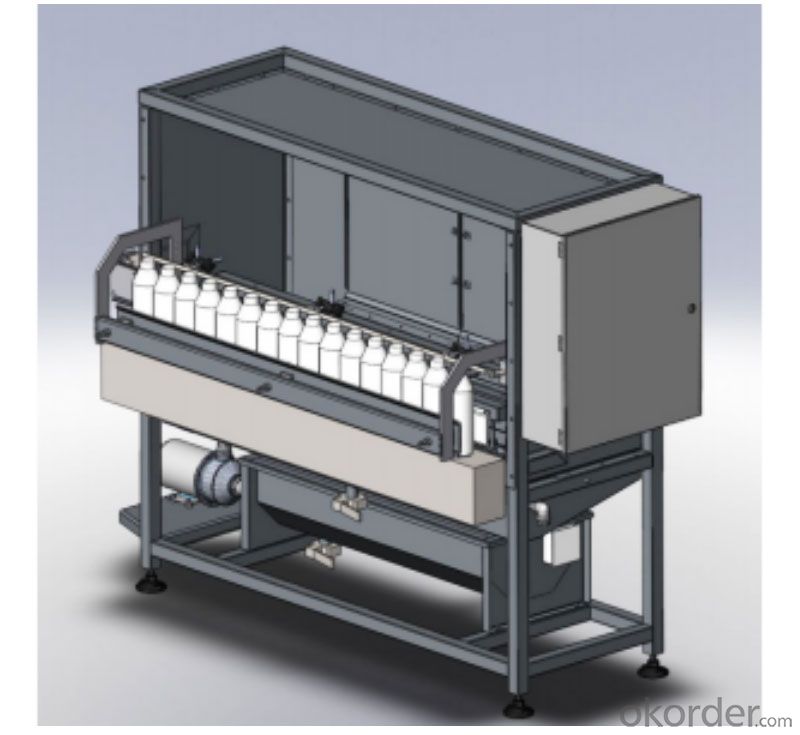

JPACKS Automatic Linear Water Rinser is used to remove dust particles and other dry contaminants from clean containers. Typically used in the bottled water industry, this Water Rinser can also be utilized in a variety of other industries that require rinsed containers prior to filling. The containers are automatically indexed into the Rinser. The grippers capture the containers and then invert them 180 degrees over the adjustable Rinse Heads. High pressure jets individually rinse the containers internally with product water or customer-supplied rinse media. Once rinsed, containers are briefly drained and are reverted back onto the conveyor. The Automatic Linear Water Rinser comes standard with PLC Controls and color touch screen HMI, Pneumatic Indexing Gates, No bottle/No rinse and Bottle Backup Sensors, plus many more. Additional options are available for even more versatility.

2、Standard Features:

1 Fingertip knob adjustable jets for different bottle width

2 PLC Controls with color touch screen HMI

3 Pneumatic Indexing Gates (Entry and Exit)

4 Overall electronic production counter

5 No bottle/No rinse Sensor

6 Bottle Backup Sensor (downstream) delays operation 1.7 until jam is cleared

7 On/off and speed controls for Conveyor

8 10 memory locations for rinse and indexing recipes

9 Front panel Start and Emergency Stop

10 Mounted on 4 heavy duty casters, plus threaded leveling legs

3、Specifications:

1 Standard Construction: Heavy duty 304SS 48” frame with some anodized aluminum

2 Rinse Head: Virtually all container sizes

3 Rinse Time: Variable, typically 2 to 3 seconds per container

4 Standard Line Height: Typically 36”

5 Power Requirement: 220VAC, single phase, 30 amp, 50-60Hz

6 Air Requirement: 2CFM @ 90PSI clean, dry, compressed air

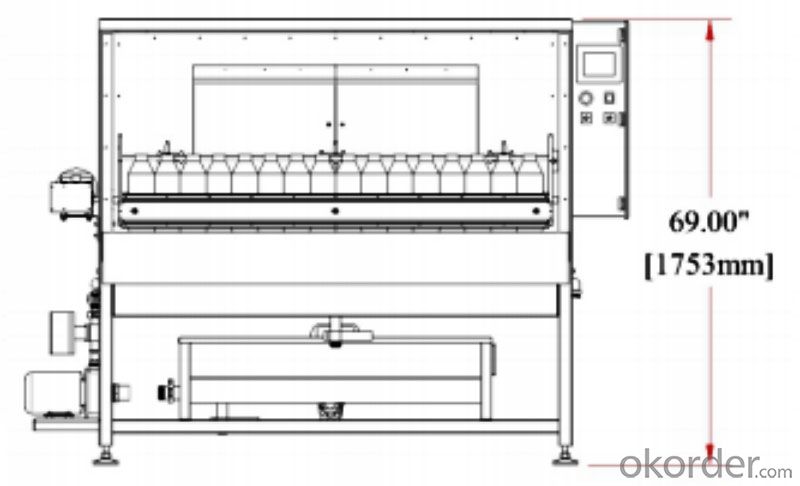

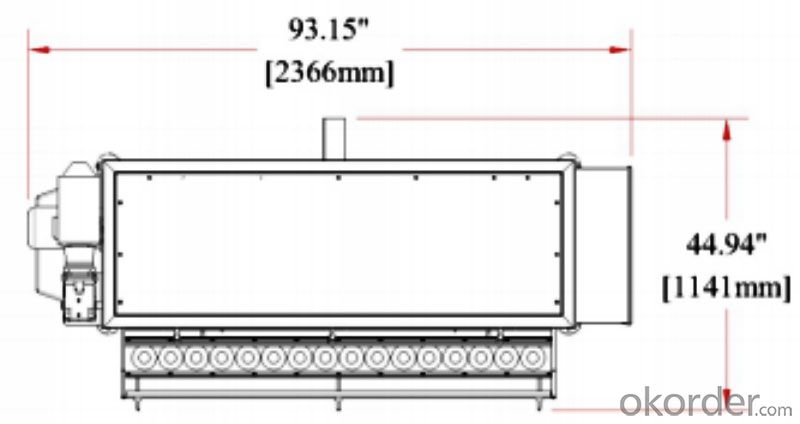

7 Dimensions & Weight: Subject to model configuration

4、Options:

1 1 to 16 Rinse Heads

2 Larger frame for more Rinse Heads

3 Air Knife

4 Custom applications

5 Special electrical requirements

6 Sanitary, hazardous, flammable and corrosive environment construction

5、Images:

FAQ

Q1: What is your delivery time?

A: Generally, the delivery time is 45-60 days after receive the deposit, big production line may take more time.

Q2: What is the payment term?

A: We accept both T/T and L/C. Most customers pay by T/T.

Q3: What kind of after-sevices do you provide?

A: If it is not big problem, we can solve it by emails, phone etc. If it can’t work, our engineers can go to overseas to install and adjust the machine and solve the problems.

- Q: What is the charge for packing materials?

- The material packing fee belongs to the productive circulation expenses, mainly including the packing cost, storage and keeping charge, loading and unloading fee, finishing fee and so on.

- Q: What are the packing materials for heavy cargo transportation?

- The bulky goods need to use fixed bandages, tie belt, to prevent the occurrence of collision in the process of transportation, damage. Dragon Century Logistics has made big transport in Hongkong, and the handling and strengthening of large cargo before shipment are more mature.

- Q: What packing materials should be understood in purchasing?

- Other specific products, specific problems specific analysis, because the product form is not the same, liquid or chemical products packaging is not the same, the general small commodities, daily necessities of packaging almost the same

- Q: What are the common material choices, printing options and common sense?

- Health gift box: the use of 157G coated paper laminating grey board or board, can also be wove paper or other special craft paper.Printing: 4+0C printing, printing spot colors, gold or silver.After the process: light glue, matte plastic, local UV, matte, hot embossing, platinum (metallic film with gold, silver, blue and other colors for choice) or anti-counterfeit film (so that others can not copy), inner box (internal) model and separated model. The common silk cloth, sponge or foam mounted flocking plastic materials. The handicraft is elaborately done by hand. Selection of materials according to product needs and grades to choose, to ensure that the United States and the concept of economic and practical.

- Q: How to prevent the use of packaging materials during production without error?

- Strengthen supervision, special packaging materials can be set up straight personnel.Management must be one to one or one to many, not many to one management. Otherwise easily confused.Do a good job of late entry, ensure that products correspond to their place.I hope I can help you.

- Q: Which industry does the packing product belong to?

- 1, the realization of commodity value and use value, and is to increase the value of goods as a means;2, protect the commodity from the sun, wind, rain, dust and other natural factors of invasion, to prevent volatilization, leakage, melting, contamination, collision, extrusion, loss and theft and other losses;3, to the circulation of storage, transportation, adjustment, marketing convenience, such as loading and unloading, inventory, palletizing, delivery, delivery, transportation, sales, counting, etc..4, landscaping and attract customers, is conducive to promotion.5, as for people or things in the image of the dress up, landscaping, more attractive or commercial value.

- Q: What plastic packaged food is safer?

- PP plastic food packaging materials, PP special soft, good toughness, non-toxic, high temperature resistant, often make catering appliance or other high-temperature packaging products, our hotel is packed with PP material boxes.

- Q: What material is the vacuum packing bag, please?

- Vacuum packaging is a general term for flexible packaging composite membrane products. If the temperature is different, there will be a lot of division: there is less than 100 bactericidal, and some need 100 degrees of sterilization, and 121 degrees and 135 degrees. Of course, there is also room temperature, the choice of this temperature under the condition of the sterilization method is irradiation sterilization. And also consider the content and weight of the package to determine the reasonable use of the packaging materials. There is no static, and the right is the best.

- Q: What's the difference between the materials used in kraft paper packaging?

- Kraft paper, packaging, color boxes, books, flowers, etc., is very goodAccording to the kraft paper kraft paper packaging is often used for Baixin generally useful good grades three points almost useful useful still better.Almost crisp, the surface is not so smooth, generally more smooth, stiffness, tension, a little better, the better is the double-sided smooth, similar to cement bags that kind of paper packaging is sure that the wood has a problem ~!

- Q: What's the difference between a package and a package?

- Packaging refers to the packaging of various types of containers, such as barrels, boxes, bags, bottles, etc., for the purpose of packing the goods of this enterprise. Packaging materials, such as paper, rope, wire, iron sheet, etc., these are disposable packaging materials, should be used as raw materials for accounting. Accounting items; turnover materials - packaging

Send your message to us

JXP-180 Automatic liner Bottle Rinser

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 30 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords