JLP-200H Automatic Bottle Unscrambler Machine

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 30 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1、Product Details

JLP-200H Automatic Bottle Unscrambler is making up of bottle elevator ,round plate,bottle rejector, bottle-arranging and the electrical cabinet . Put disordered bottles to the bottle elevator, through round plate, conveying belts, bottle arranging parts , then bottles can stand on the belts. This machine is characterized by the compact structure, simple operation principle, mature technique and stable movement.

Bottles poured into the rotator plate, with belts conveying to the unscrambling device; bottle standing orderly on the conveyor belts. This machine is of high speed, round and flat bottle both applicable. No need to change any part when changing the bottle specification. It is with auto rejecter and no-bottle alarm function.

2、Features

2.1 Simple structure and easy operation and convenient adjustment. And the normal same series machine sells on the market are much larger than us with three meters’ length and heavy weight.

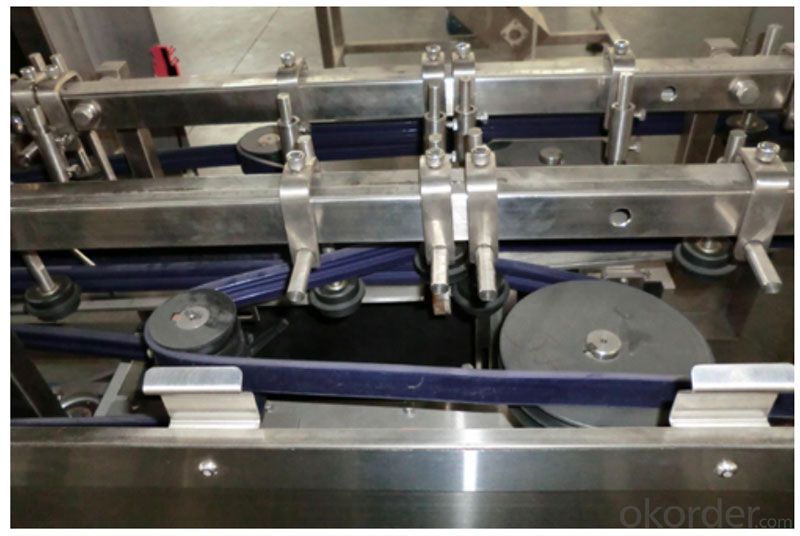

2.2 When changing different bottle size, you do not need to change anything, you only need to change the belt in the bottle hopper and adjust the space of the unscrambling structure. And it is applied to 50-1000ml.

Adjust the space of the bottle unscrambling structure according to the bottle size

2.3 Adopted the US technology, good stability and the qualified rate is 100%.

2.4 The electrical components are all imported which ensures its long service time and stability.

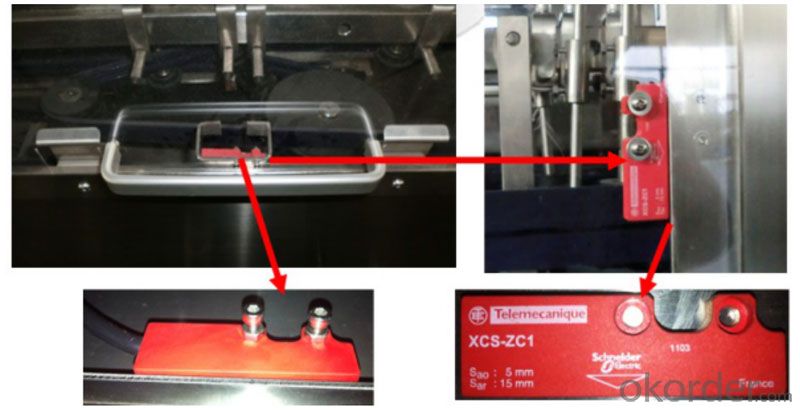

2.5 The whole machine is covered with organic glass, you can open all the cover for easy adjustment.

2.6 All the organic glass cover is installed with the sensor. The machine only can start when all the organic glass cover are closed,and will stop when any of the door is open.

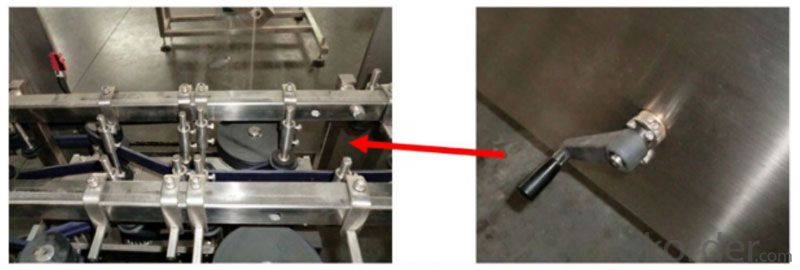

2.7 The connecting belt in the machine are shaped in one time, not easy to broken.

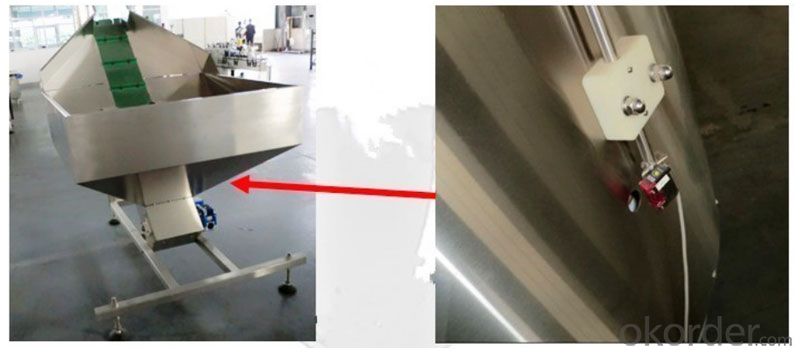

2.8 Automatic bottle elevating function, you only need to put the bottles in the bottle elevator, a sensor is installed in the rotary plate, it will automatically elevates the bottles when there is not enough bottle, it will start when the bottles are enough consequently.

2.9 Coordination sensor, it will stop bottle unscrambling when there is jam of the other sections of the filling line, it will start again when the jam is cleared. It will have the perfect linkage with the other sections of the filling line.

3、Main Technology Parameter

3.1 Unscrambling Speed:≤ 200 bottles/min

3.2 Applicable Bottle Diameter:Φ45-90mm

3.3 Applicable Bottle Height:80-240mm

3.4 Air Pressure:0.5~0.7 MPA

3.5 Power Source:~220V、50HZ

3.6 Power:1.5KW

3.7 Bottle Unscrambler External Dimension:2600mm×1500mm×1500mm(L×W×H)

3.8 Weight:About 1250Kg

4、Allocation

4.1 Frequency converter: Japan Omron

4.2 Magnetic Switch: France Schneider

4.3 Sensor: Japan OPTEX

4.4 Power Switch: France Schneider

4.5 Cylinder: Japan SMC

FAQ

Q1: What is your delivery time?

A: Generally, the delivery time is 45-60 days after receive the deposit, big production line may take more time.

Q2: What is the payment term?

A: We accept both T/T and L/C. Most customers pay by T/T.

Q3: What kind of after-sevices do you provide?

A: If it is not big problem, we can solve it by emails, phone etc. If it can’t work, our engineers can go to overseas to install and adjust the machine and solve the problems.

- Q: What packing materials should be understood in purchasing?

- Other specific products, specific problems specific analysis, because the product form is not the same, liquid or chemical products packaging is not the same, the general small commodities, daily necessities of packaging almost the same

- Q: Billycan what are the advantages compared with other packaging materials?

- The decoration is exquisite: the metal material has good printing performance; the design trademark is bright and beautiful; the packaging container made by it is noticeable, and it is a kind of good sale packing.

- Q: What's the difference between bulk food and prepackaged food?

- Is a small workshop to provide containers, that is, pre packaged food, is to take their own containers to buy, that is, bulk food

- Q: What is accessory material? What is the difference between it and raw material?

- From this we can see that the auxiliary material is one of the raw materials and belongs to the raw material.For example: to make green pepper fried meat, then oil, salt, sauce, vinegar and other spices are auxiliary materials, and green peppers and meat is the raw material or main material, but they are the raw materials for stir frying.

- Q: Cookies with tinplate packaging has what advantage

- Mature technology and high production efficiency: the production of tinplate has a long history, mature technology is a set of production equipment with matching, high production efficiency, can meet a variety of product packaging needs.

- Q: What's the difference between the materials used in kraft paper packaging?

- Semi Kraft kraft wrapping paper: General tensile, color is also very general, if there is no requirement for appearance, you can use semi wood pulp, kraft paper.

- Q: Does the desiccant belong to the packing material?

- Many used desiccant is involved in metal industry, some equipment and parts in the transport process, to prevent corrosion, reduce the humidity inside the packaging, the possibility of reducing dew temperature, the general formula is the packaging materials used.

- Q: What kind of fruit package do you have?

- Fruit packaging, pet plastic fruit packing box, PET material, environmental protection non-toxic, not only moisture-proof, the product is also transparent, beautiful, smooth, light weight. And there are air holes, to ensure the flow of air, but also affixed labels, indicating fruit information, so that customers at a glance.

- Q: Is the antistatic value of PS material (or other packing material) as small as possible?

- Not necessarily. This needs to be decided in terms of specific areas of use and requirements.The so-called antistatic refers to reach 10 between the 7-10 sides.And the 1-6 side of the 10 is generally referred to as electrical conduction.

- Q: What's bread packing? Polyethylene film, waterproof cellophane, etc.

- More importantly, the use of aluminum foil / composite or polyethylene composite or aluminum foil / polyethylene composite material. Although this type of packaging is opaque, it protects against loss of vitamin B1 in bread.

Send your message to us

JLP-200H Automatic Bottle Unscrambler Machine

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 30 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords