Raw Materials for Refractory - Japan Supplier of Blast Furnace of CNBM in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m.t.

- Supply Capability:

- 10000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Calcined Bauxite Description

Bauxite (aluminous soil; Bauxite) is also called the alumina or bauxite, main ingredients are alumina, hydrated alumina containing impurities, is an earthy mineral. White or gray, brown and yellow or light red by iron.

Japan Supplier of Blast Furnace of CNBM in China

2.Main Features of the Calcined Bauxite

Calcined bauxite is one of the principal ore of aluminum. Calcined bauxite contains hydrous aluminum oxides and aluminum

hydroxides, formed through the laterization of aluminous rocks in tropical and subtropical areas .Calcined bauxite is obtained by calcining (heating)superior grade bauxite at high temperature (from 85OC to 1600C) .This removes moisture there. By increasing the alumina content,compared to an alumina content of about 57%to 58% in raw bauxite, calcined bauxite has an alumina content of 84%to88%.The heating is carried out in rotary kilns.

Japan Supplier of Blast Furnace of CNBM in China

3.Main usage of the Calcined Bauxite

(1) aluminium industry. Used in national defense, aerospace, automotive, electronics, chemical industry, daily necessities, etc.

(2) precision casting. Alumina clinker made after the mould precision casting processed into fine powder. Used in military industry, aerospace, communications, instrumentation, machinery and medical equipment department.

(3) is used for refractory products. High bauxite clinker refractoriness is as high as 1780, chemical stability strong, and good physical properties.

(4) aluminum silicate refractory fiber. With light weight, high temperature resistance, good thermal stability, low thermal conductivity, heat capacity is small and the advantages of resistance to mechanical shock. Used in iron and steel, nonferrous metallurgy, electronics, petroleum, chemical, aerospace, atomic energy, defense and other industries.

Japan Supplier of Blast Furnace of CNBM in China

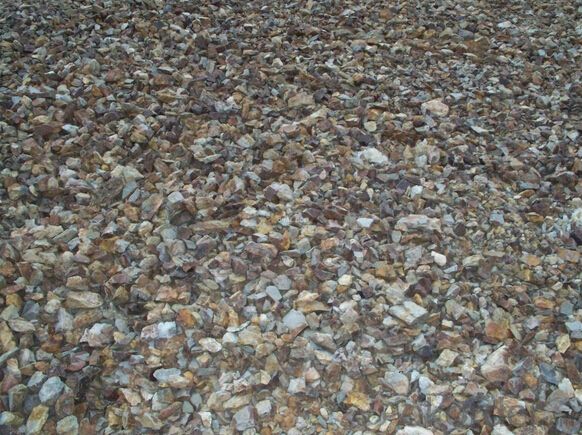

4. Calcined Bauxite Images

Japan Supplier of Blast Furnace of CNBM in China

5. Calcined Bauxite Specification

tem | Data | |||||||

Chemical index | Al2O3 | Fixed Carbon | SiC+Si3N4 | H2O | ||||

≥35 | ≥ 12 | ≥ 18 | ≤3.0 | |||||

Physical Index | Refractoriness | Refractoriness under load | Cold Crushing Strength (1350*9h) | Cold Breaking Strength (1350*9h) | AP (1350*9h) | Bulk density (1350*9h) | Marshall value (50Mpa) | |

≥ 1600 | ≥ 1300 | ≥10 | ≥5 | ≥ 27 | ≥175 | 0.6-1.2 | ||

6.FAQ of Calcined Bauxite

1). Q: Are you a factory or trading company?

A: We are a factory.

2). Q: Where is your factory located? How can I visit there?

A: Our factory is located in ShanXi, HeNan, China. You are warmly welcomed to visit us!

3). Q: How can I get some samples?

A: Please connect me for samples

4). Q: Can the price be cheaper?

A: Of course, you will be offered a good discount for big amount.

- Q: who knows the fire resistant levels of fireproofing glass?

- Fireproofing glass is a kind of special glass which can keep its integrity and thermal insulation performance in regular insulating refractory trials. and it can be divided into three classes according to its fire resistance: Class A, it's a kind of fireproofing glass that can satisfy the requirements of refractory integrity, refractory and thermal insulation at the same time. This kind of glass has the properiyies of transmittance, fireproofing ( smoke insulation, fireproofing, and keeping out thermal radiation), sound insulation, shock resistance, and it's suitable for steel and wooden fire door of building decoration, windows, varnishing, partition walldaylighting?roof,ceiling?screen,perspective floor and other construction components demading for transparency and fireproofing. Class B, it's a kind of fireproofing glass that can satisfy the requirements of refractory integrity, refractory and thermal insulation at the same time. Such kind of fireproofing glasses mostly are composite fireproofing glasses and has characteristics of transmittance,fireproofing and smoke insulation. Class C, it's a kind of fireproofing glass that only satisfies the requirements of refractory integrity. This kind of glass has characteristics of transmittance, fireproofing, smoke insulation and high strength,etc. It's suitable for fireproofing glass partition wall, fire Windows, outside curtain wall and other places without insulation requirements. Classify from the structure,fireproofing glass can be divided into composite fireproofing glass and monolithic fireproofing glass.

- Q: How long is the fire endurance of Grade A fire resisting shutter

- Fire door can be divided into Grade A, Grade B and Grade C fire door according to its fire endurance. Their fire endurance is not less than 1.20h, 0.90h and 0.60h respectively. Use fire resisting shutter as fire?compartment separation in places where it is difficult to set firewall. When fire resisting shutter whose unexposed surface temperature rise is used as judging condition of fire endurance is used, its fire endurance should not be lower than 3h. When fire resisting shutter whose unexposed surface temperature rise is used as judging condition of fire endurance is not used, individual protection of ?closed automatic water spray system shoule be set at two sides of the shutters and duration of water spray system should not be less than 3.0h. When the fire resisting shutter is used for fire?compartment, fire endurance is 3h. When the fire resisting shutter is set at the opening part of firewall, fire endurance is 1.2h.

- Q: Is there requirement for radiation indicator in refractory?

- All refractories have no radiated harm to environment, so there is no requirement. From the elemental analysis, magnesite. I do not know it is helpful to you. But for refractory rwa material, any chemical element is radiated, including silicon?dioxide; If they are radioactive. From the use analysis, such as bauxite, do not have use value.

- Q: Where is the sizing nozzle for refractories? Just enter the line, master into!

- Hua Heng refractories in the industry reputation is good, especially in the Southern small steel sales are among the best!

- Q: I would like to know if there is any requirement for refractories in the crucible type high-frequency smelting furnace Worry! I hope you can help me! This time!

- High enough for high temperature resistance. Refractory materials for crucibles shall be subjected to a high temperature greater than 1700 DEG C and the softening temperature shall be greater than 1650 DEG c;

- Q: Is the refractory reached British BS standard and used for cables in China at present ceramic silicone rubber?

- The texture should be designed according to the British relevant BS standard; crosslinked polyethylene or ethylene propylene rubber under 6600V to 19000 / 33000V is not necessarily ceramic silicone. The rated voltages of a small amount of smoke and corrosive gases from 3800 & # 47 when the BS 7835-2000 is affected by fire.

- Q: What is refractory aggregate?

- It includes two categories: coarse aggregate and fine aggregate.

- Q: What's the type of fire proofing thermal insulation materials?

- Aluminum silicate: AlSiO3 With flint clay clinker as raw material, aluminum silicate is made by resistance or electric-arc furnace fusion and then spraying processing. Aluminum silicate fiber, also known as ceramic fiber, is a new lightweight refractory material featured by light weight, high temperature resistance, good thermal stability, low heat conduction rate, small heat capacity, good mechanical vibration resistance, small thermal expansion and good thermal insulation. It can be processed into aluminum silicate fiber board, aluminium silicate fiber felt, aluminium silicate fiber rope, aluminium silicate fiber blanket, etc. Featured by high temperature resistance, low heat conductivity coefficient, light weight, long life, good tensile strength and elasticity and no toxin, this new sealing material is an alternative of asbestos and widely used for thermal insulation of thermal energy equipment in metallurgy, electric power, machinery, chemical industry, etc.

- Q: On the problem of making refractory materials

- Refractories mainly depend on their high melting point characteristics. The refractory market is mainly Magnesium Oxide material.

- Q: How do refractory materials apply into pyrophyllite?

- When it is sized, add some clinker and after calcination, aggregate will be finished. From: turn to help

Send your message to us

Raw Materials for Refractory - Japan Supplier of Blast Furnace of CNBM in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m.t.

- Supply Capability:

- 10000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords