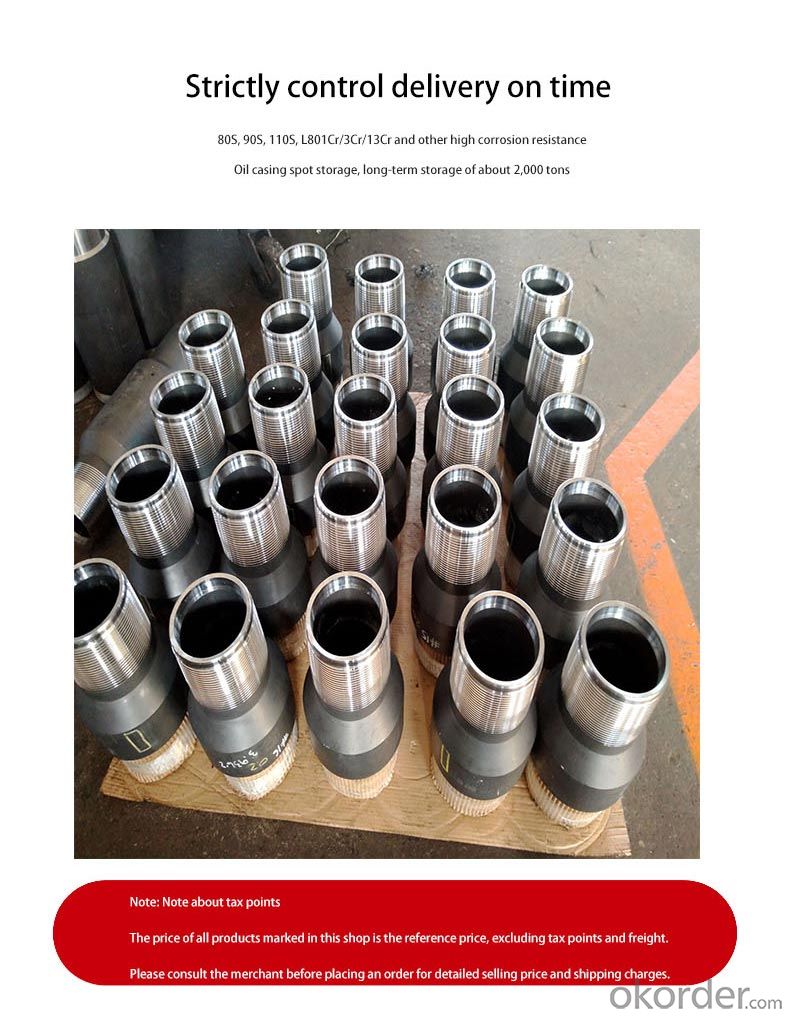

J55-L80 Grade Direct-Supply Deep Well Casing, Precision Thread, Reliable Quality, Cost-Effective

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1100 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

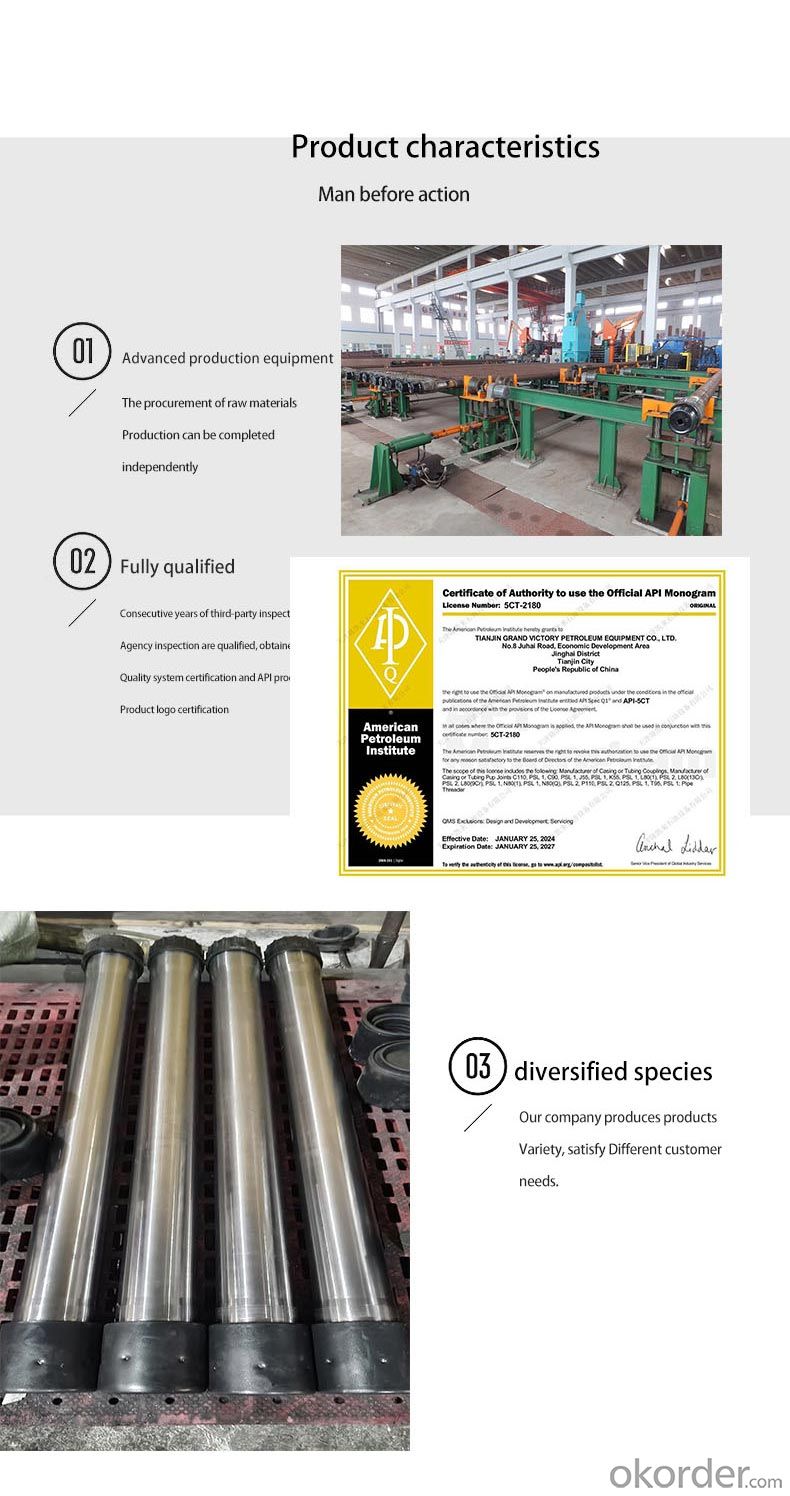

API 5CT J55/N80/P110 OCTG Casing & Tubing Manufacturer Direct

Comprehensive OCTG Solutions for Every Well Profile

As an API-licensed manufacturer, we eliminate intermediaries to deliver J55/N80/P110 casing and tubing with 15% cost savings. Our vertically integrated production process ensures full traceability from steel billet to finished product.

Technical Specifications

Material Science:

J55: 0.45% Mn, 0.25% C composition for shallow wells (≤8,000ft TVD)

N80: Quenched & tempered microstructure withstands 12,000psi collapse pressure

P110: 110ksi SMYS with Charpy V-notch impact ≥45J at -20°C

Threading Technology:

CNC-machined API LTC/BTC threads with ±0.003" pitch diameter tolerance

Optional VAM TOP connections for HPHT wells

Quality Assurance:

100% ultrasonic testing (UT) for laminations

Hydrostatic tested to 80% of yield strength

Applications

J55: Water injection wells, surface casing

N80: Intermediate casing in sour gas fields

P110: Production casing in 15,000psi reservoirs

Case Study

A Permian Basin operator reduced casing costs by 18% using our direct-shipment P110 casing for 35 horizontal wells, achieving 95% torque-turn compliance during running

- Q: How can the immersed pipe pile put steel cage into the steel pipe? Which expert to answer?

- The pile reinforcement cage construction characteristics: in general application of the reinforcement cage can be used when not required manual assembling reinforcement cage, such as deep or large pile diameter should be used for solid and solid mechanism of reinforcement cage better (by reinforcing cage seam welder production) to meet Zhuang Jishi high technology requirements, enhance the stability of pile foundation.

- Q: How are steel pipes used in the manufacturing of heat exchangers?

- Steel pipes are commonly used in the manufacturing of heat exchangers due to their excellent heat transfer properties and durability. They are utilized as the main components for carrying and transferring hot or cold fluids within the heat exchanger system. The steel pipes ensure efficient heat exchange by providing a smooth and continuous flow of the fluid, while also withstanding high temperatures and pressures. Additionally, steel pipes are often preferred for their corrosion resistance, making them suitable for various industrial applications requiring reliable and long-lasting heat exchangers.

- Q: Can steel pipes be used for oil refinery applications?

- Yes, steel pipes can be used for oil refinery applications. Steel pipes offer many advantages for oil refinery applications including high strength, durability, and resistance to corrosion. They are able to withstand high pressure and temperature conditions that are common in oil refinery operations. Steel pipes are also easy to transport and install, making them a popular choice for oil refinery projects. Additionally, steel pipes can be customized to meet specific requirements such as size, thickness, and coating, making them suitable for a wide range of oil refinery applications.

- Q: What is the density of steel pipes?

- The density of steel pipes varies depending on their composition, but on average, the density of steel pipes is around 7.8 grams per cubic centimeter.

- Q: Can steel pipes be used for hydroelectric power plants?

- Yes, steel pipes can be used for hydroelectric power plants. Steel pipes are commonly used in hydroelectric power plants for various applications. They are primarily used in the penstock, which is a pipe that carries water from the reservoir to the turbine. The penstock is under high pressure, and steel pipes have the necessary strength and durability to handle the pressure and flow of water. Steel pipes are preferred in hydroelectric power plants due to their high tensile strength, corrosion resistance, and longevity. They can withstand the high-pressure conditions and flow rates of water, ensuring the efficient transfer of water from the reservoir to the turbine. Additionally, steel pipes have the advantage of being easily fabricated and installed. They can be customized to fit specific project requirements and can be welded or bolted together to form the desired length and shape. Furthermore, steel pipes are cost-effective compared to other materials commonly used in hydroelectric power plants, such as concrete or fiberglass. They provide a reliable and cost-efficient solution for conveying water in hydroelectric power plants, contributing to the overall efficiency and effectiveness of the power generation process. In conclusion, steel pipes are a suitable and commonly used material for hydroelectric power plants. They offer the necessary strength, durability, and cost-effectiveness required for conveying water from the reservoir to the turbine, making them an ideal choice for this application.

- Q: Can steel pipes be used for solar energy systems?

- Yes, steel pipes can be used for solar energy systems. Steel pipes are often used for the construction of solar water heating systems, solar thermal collectors, and solar panel mounting structures. They are durable, cost-effective, and provide the necessary support for various components of a solar energy system.

- Q: How does galvanization protect steel pipes from corrosion?

- Galvanization protects steel pipes from corrosion by applying a protective zinc coating on the surface of the pipes. This zinc coating acts as a sacrificial anode, meaning it corrodes first before the steel, effectively preventing rust and corrosion from reaching the underlying steel.

- Q: Can steel pipes be used for geothermal systems?

- Yes, steel pipes can be used for geothermal systems. Steel pipes are commonly used in geothermal systems due to their durability, high strength, and resistance to corrosion. They can effectively handle the high temperatures and pressures associated with geothermal operations, making them a reliable choice for transporting geothermal fluids. Additionally, steel pipes are readily available and cost-effective, making them a practical option for geothermal system installations.

- Q: How are steel pipes classified based on their diameter?

- Steel pipes are classified based on their diameter by categorizing them into different size ranges, such as small diameter pipes, medium diameter pipes, and large diameter pipes.

- Q: Are steel pipes suitable for conveying fluids?

- Steel pipes are well-suited for the transportation of fluids. They have been extensively utilized across various industries for numerous years due to their robustness, strength, and resistance to corrosion. These characteristics render steel pipes an optimal choice for the conveyance of fluids like water, oil, gas, and hazardous substances. Moreover, the sleek interior surface of steel pipes facilitates smooth flow and prevents blockages, thus making them appropriate for applications that necessitate uninterrupted and seamless fluid movement. Additionally, steel pipes can endure high-pressure and high-temperature conditions, enabling their use in both high and low-pressure fluid transmission systems. In summary, steel pipes are a dependable and efficient alternative for fluid conveyance in a wide array of industries, including oil and gas, water treatment, chemical processing, and many others.

Send your message to us

J55-L80 Grade Direct-Supply Deep Well Casing, Precision Thread, Reliable Quality, Cost-Effective

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1100 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Related keywords