Irradiation cross-linkable PVC compound

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 3000 Tons kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Irradiationcross-linkable PVC compound

I. Type andapplication

Type | Product | Application and Cable Specification |

1151N | 105℃ Irradiation cross-linkable PVC insulating compound | Used for irradiation cross-linkable cables and wires which working temp. of conductor is 105℃ |

1152N | 105℃ Irradiation cross-linkable PVC jacket compound | Used for irradiation cross-linkable cables and wires which working temp. of conductor is 105℃ |

1151N-R | 105℃ Irradiation cross-linkable PVC insulating compound | Used for irradiation cross-linkable cables and wires which working temp. of conductor is 105℃, according with JASO D618-2008 XLPVC standard. |

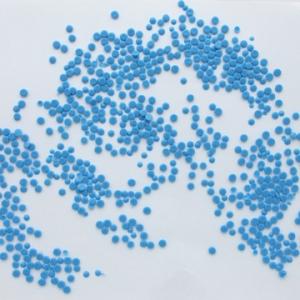

II. Productdescription

Irradiation cross-linkable PVC compound forcables and wires, based on PVC resin, is made into granula by specialprocessing with adding plasticizer, stabilizing agent, cross-linking agent andother special agents. The products meet various special requirements, such asdifferent hardness, UV stable, environment friend (RoHs, REACH, PAHs,chlorinated alkanes free, phthalatefree, and etc.), sub-shine and fog surface, low temperature resistant, PS/ABStransfer proof, rodent-repellent, termite-repellent, and transparent, and etc.

III. Irradiatingdosage

The normalirradiating dosage of irradiation cross-linkable PVC compound is 6-8 mega-rad.

Note: For the compound would be coloured if the white and nature colourcompound were irradiated directly, the compound need add white colourmasterbatch before processing.

IV. Processing

It is recommended that compound should beprocessed with common extruder having a minimum L/D ratio of 20. Non-specialrequirements of equipment and processing are needed.

The following temperature(℃) profileof extruder is recommended

Zone | Zone 1 | Zone 2 | Zone 3 | Zone 4 | Head | Die |

Temperature ℃ | 140 | 160 | 170 | 175 | 180 | 175 |

V. Storageand transport

Packaging:25kg/bag, PEmembrane inside bag and Kraft outside bag.

Storage and transport: Avoiding in directsunlight and weathering. The storage place should be in clean, cool, dry, andventilated conditions.

VI. Properties

Table

Item | Unit | Standard Value | |||

1151N | 1152N | 1151N-R | |||

Tensile Strength | ≥ MPa | 16.0 | 15.0 | 16.0 | |

Elongation at Break | ≥ % | 150 | 180 | 150 | |

Impact Brittleness Temperature | ≤ ℃ | -15 | -20 | -20 | |

Volume Resistivity, at 20℃ | ≥Ω﹒m | 1.0×1011 | 1.0×108 | 1.0×109 | |

Volume Resistance at working temperature | Temperature | ℃ | 95±1 | — | — |

Volume Resistance | ≥Ω﹒m | 1.0×108 | — | — | |

Dielectric Strength | ≥ MV/m | 20 | 18 | 20 | |

Hot Deformation | ≤ % | 40 | 50 | 40 | |

Thermal Stability Time at 200℃ | ≥ min | 120 | 120 | 120 | |

Oxygen Index | ≥ % | - | 26 | — | |

Thermal Prolongation Elongation Under Load | ≤ % | 175 | 175 | 175 | |

Thermal Aging |

|

|

|

| |

Aging Temperature | ℃ | 136±1 | 136±1 | 136±1 | |

Aging Time | h | 168 | 168 | 168 | |

Retention of Tensile Strength | ≤ % | +80 | +80 | +80 | |

Retention of Elongation at Break | ≤ % | +75 | +70 | +75 | |

Note: The above data are the compoundproperties after irradiated.

- Q: Can olive nets be used to protect against hail damage?

- Yes, olive nets can be used to protect against hail damage. Olive nets are commonly used in agriculture to cover crops and provide protection against various weather elements, including hail. The nets create a barrier that helps absorb the impact of hailstones, reducing the potential damage to the plants.

- Q: Can olive nets be customized for specific orchard requirements?

- Yes, olive nets can be customized to meet specific orchard requirements. These nets can be tailored in terms of size, shape, and material to ensure optimal coverage and protection for olive trees in different orchards. Customization allows for better adaptation to specific orchard layouts, tree sizes, and climatic conditions, ultimately enhancing the effectiveness and efficiency of olive tree cultivation.

- Q: What is the material of plastic bottles? Will plasticizers be produced?

- Plastic bottles are made of polyethylene or polypropylene and added a variety of organic solvents. Most of the beverage bottles are made of plastic. The two materials, polyethylene and polypropylene, are non-toxic and tasteless. They are used for filling drinks and so on. They are very safe for the human body. But once the polyethylene is subjected to high temperature or acid corrosion, it dissolves slowly and releases organic solvents, which can cause harm to the human body.

- Q: Are there any specific guidelines for using olive nets on olive trees with specific soil requirements?

- Yes, there are specific guidelines for using olive nets on olive trees with specific soil requirements. The soil should be well-drained and have a pH level between 6 and 8, as olive trees thrive in these conditions. Additionally, it is important to avoid excessive watering, as it can lead to root rot. Proper soil preparation, including adding organic matter and ensuring proper drainage, is crucial for successful olive tree cultivation with the use of olive nets.

- Q: Can olive nets be used for olive tree temperature regulation?

- No, olive nets are primarily used for protecting the olives from birds and other pests, not for temperature regulation of the olive tree.

- Q: How do olive nets prevent damage from wind-blown debris?

- Olive nets prevent damage from wind-blown debris by acting as a protective barrier around the olive trees, preventing the debris from directly hitting the trees and causing damage.

- Q: Do olive nets have any impact on the taste of olives?

- Yes, olive nets can have an impact on the taste of olives. When olives are left on the tree for an extended period of time, they can become overripe and lose their desirable flavor. Olive nets help to prevent olives from falling to the ground, protecting them from damage and reducing the risk of overripening. By keeping olives fresh and intact, olive nets can contribute to maintaining the optimal taste of the olives.

- Q: How does an olive net affect the overall fruit ripening in the olive grove?

- An olive net can have a positive impact on the overall fruit ripening in an olive grove. By covering the trees with a net, it provides protection from birds and other animals that may feed on the ripening olives. This allows the olives to fully mature and ripen on the tree, resulting in a higher quality and better tasting fruit. Additionally, the net can also provide shade to the trees, which helps regulate temperature and moisture levels, creating optimal conditions for fruit ripening.

- Q: Can olive nets be used in both small and large-scale olive farms?

- Yes, olive nets can be used in both small and large-scale olive farms. The nets are designed to protect the olives from birds, pests, and harsh weather conditions, regardless of the size of the farm. They are adjustable and can be easily installed in various configurations to cover the olive trees efficiently, making them suitable for both small-scale and large-scale farming operations.

- Q: How do olive nets protect olives from wind damage?

- Olive nets act as a physical barrier, preventing strong winds from directly hitting the olives. This protects the delicate olive fruits from being knocked off the branches or damaged by the force of the wind, ensuring a higher yield and better quality olives.

Send your message to us

Irradiation cross-linkable PVC compound

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 3000 Tons kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords