Insulation Paper for Liquid Nitrogen Storage

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

The fire retardation glass fiber Cryogenic & Insulation paper is made of superfine glass fiber with special processing. This is usually used with aluminium foil and used for transport containers which store liquid helium, liquid hydrogen, liquid nitrogen,LNG etc.

The superfine glass fiber Cryogenic & Insulation paper's diameter between 0.1-0.6μm and fiber glass filament (diameter between 3-5 μm). According to a certain proportion, the paper is produced under the wet & vacuum forming process to make the paper have the space lattice structure. All the glass fiber is inorganic material, so it has outstanding flame retardant properties. Specifically engineered for use at big temperature range (approaching -273℃—500℃) and also the paper is really stable in the low temperature condition.

Cryogenic Insulation Paper Features:

The main way of heat conduction is by radiation heat exchange in the low and vacuum condition. In order to reduce the radiation heat exchange to meet the good heat insulation effect, by using aluminum foil for reflecting screen and superfine glass fiber insulation paper for spacer, then the multilayer combination of aluminum foil reflective screen and cryogenic & insulation material can build up the efficient thermal barrier against heat transfer in insulated vacuum storage containers. This material can be freely winding, and help the user to reduce the waste of manpower and material waste.

Cryogenic Insulation Paper Application:

Cryogenic liquid (liquid helium, liquid hydrogen, LNG, liquid oxygen, liquid nitrogen, liquid argon, etc.)

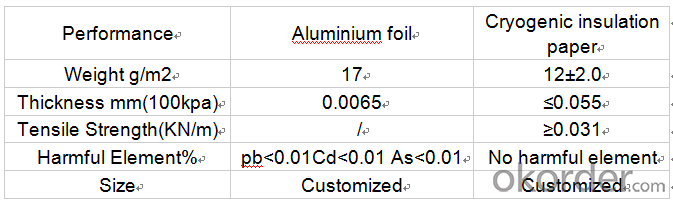

Cryogenic Insulation Paper Specifications

1.light weight

2.good uniformity

3.low thermal conductivity

Technical data:

Q1 What’s the transport method?

A1 FCL delivery goods with wooden pallet; If LCL delivery, must with wooden case; Sometimes need open top, flat rack or bulk cargo.

Q2 What’s the required payment term?

A2 Generally 30% TT as the prepayment, 70% TT before delivery. If need, 100% Irrevocable Letter of Credit or negotiation.

Q3 Which country are our products exported to?

A3 Apart from entire Chinese market, the US, Russia, Japan, Korea, Australia and some Southeast Asian Nations.

- Q: National medical equipment use personnel ability to assess the qualifications required to confirm what documents required

- "2014 annual national medical equipment use business ability assessment application form" and other related documents, a copy of the material express to the designated location. ? After the registration qualification, candidates can be in the October 30 - November 8 log on China Health Network, download print admission ticket. ? Fifth, evaluation methods ? The evaluation date is November 8, 2014, the specific assessment of the professional schedule to prevail, subject to the use of closed paper pencil answer.

- Q: How can there be a low temperature cabinet in Hangzhou

- Do low-temperature freezers to do the manufacturers or less, or you can look at Haier's. Cold snow is also doing this low temperature freezer!

- Q: Hydraulic equipment at low temperature how much the normal start

- You should ask how much more normal work in the above. Preferably above 30 ℃. 20 ℃ barely strong. And then down, your system can work properly is a problem, how much time to work is a big problem.

- Q: Cryogenic cooling circulating pump can be equipped with what equipment

- The cryogenic coolant circulation pump is a low temperature liquid recirculation machine that takes the mechanical form to cool. With the role of providing low temperature liquid, low temperature water bath. Combined with rotary evaporator, vacuum freeze-drying box, circulating water vacuum pump, magnetic stirrer and other equipment, multi-functional low temperature chemical reaction operations and drug storage.

- Q: 2015 when the medical equipment test certificate issued?

- Each time the English title test certificate to receive different time, you can on the local personnel examination network query. Evaluation of the title published papers, contact

- Q: Which industries will use ultra-low temperature equipment

- Vacuum drying, vacuum drying, vacuum drying, vacuum drying, vacuum drying, vacuum distillation, vacuum distillation, vacuum drying, vacuum drying, vacuum drying, vacuum drying, vacuum distillation technology.

- Q: How to buy medical shock wave equipment?

- Medical extracorporeal shock wave gravel equipment, generally from the following aspects of the quality of the product:

- Q: Haier medical cryopreservation box dw-40w100 how to adjust the temperature

- Look at the instructions on whether there is a solution, if there is not, Contact after sale, 4006 ... six nine Sale will give a solution, If necessary, the door will be handled!

- Q: Winter in a village of Mohe, afternoon and white in the yard to play at night to rest when the package to forget the package in the yard (the bag put a iphone, a cottage, a charger, a charge Po) , The next morning to get up when the discovery of small white hair fever, then remember to wrap in the yard, quickly rushed out to pick up the phone call 120, may I ask this phone to save the white? What about the operation of other electronic devices?

- The appropriate approach is as follows: First, the phone will be removed in the cell phone, the phone and battery were put into plastic bags, wrapped good; Second, the phone and battery together with the plastic bags are placed between 20-40 ℃ (in this range the higher the better) place (such as hot kang pot quilts, under their own armpits, their hands palm ...), the main purpose is to let the battery quickly warming; Third, as long as the battery temperature to more than zero, you can put the battery into the phone (the phone is still installed in a plastic bag, to prevent the water vapor into the phone failure), and then boot, call. As long as the appropriate way, the battery heating time will not exceed 5 minutes, usually 1-2 minutes is enough to allow the battery to restore function.

- Q: Low temperature equipment, pipes, pipe fittings have any requirements

- Ordinary pipes, pipe fittings are selected seamless stainless steel.

Send your message to us

Insulation Paper for Liquid Nitrogen Storage

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords