Tap-Out Cone Insulation Materials Ceramic Fiber Module/Uni-Felt

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction

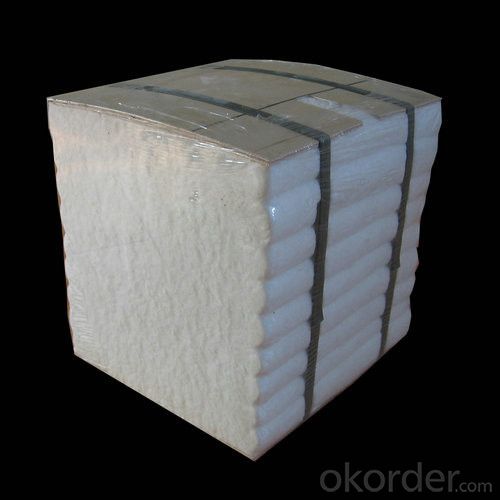

WH ceramic fiber Module is made by folding and pre-cutting WH ceramic fiber blanket, according to requests, relevant temperature stainless steel anchors can quick, easy and efficient to install and it can be used to repair old kiln.

WH ceramic fiber Uni-Felt is made if fold or pre-cut blanket stack bonded and squashing to form a module with cut edges exposed. Without any further use of binders, can be sticking with WH insulating lining by WH Ceramic Fiber. It’s easy to install and it can be used to repair old kiln and new design furnace ling.

Characteristic

Low density, low thermal capacity, low thermal conductivity

Resistance to heat shock

Resistance to airspeed eroding

Excellent mechanical strength

Good safety with anchor inside

Easy to install

Typical Application

Ceramics: shuttle kilns, tunnel kilns, kiln car, etc

Steel: heater, continuous annealing furnace, galvanizing line, kiln car, ladle cover, etc

Heat treatment: annealing furnace, normalizing furnace, tempering furnace, kiln car, etc

Petro-chemical: ethylene cracking furnace, reformer, gas flue, etc

Environmental protection: solid/flue gas treatment furnace (such as RTO furnace, etc

Mining: survival equipment (such as rescue capsule)

Product Specifications

Folded/layer module

Density: 130, 160, 192, 210,250kg/m3

Size: 300*300*150-300mm

Uni-Felt

Density: 130,160,192kg/m3

Size:300*300*50/75mm

Special specifications: size can produce according to customer’s requests

Physical & Chemical Data

product code | WHCBF-31Z/31U/31F | WHCF-32Z/32U/32F | WHCF-34Z/34U/34F | WHCF-35U/35F | WHCF-36Z/36U/36F |

1000 Uni-Felt Uni-Module/Folded-Module | 1260 Uni-Felt Uni-Module/Folded-Module | 1430 Uni-Felt Uni-Module/Folded-Module | 1500 Uni-Felt Uni-Module/Folded-Module | 1600 Uni-Felt Uni-Module/Folded-Module | |

Classification Temp. ( ℃) | 1000 | 1260 | 1430 | 1500 | 1600 |

Linear Shrikage ( % ) (℃x 24 hrs ) | 1.0(850℃) | 1.0(1100℃) | 1.1( 1200℃) | 1.2( 1300℃) | 1.1( 1400℃) |

thermal conductivity Kcal/mh℃(W/mK), (ASTM C-201 Average Temp. As belows)(Desnsity:192Kg/m3) | |||||

400℃ | 0.09 | 0.09 | |||

600℃ | 0.15 | 0.14 | 0.12 | 0.11 | 0.10 |

800℃ | 0.22 | 0.20 | 0.18 | 0.16 | 0.15 |

1000℃ | 0.21 | 0.19 | 0.18 | ||

Send your message to us

Tap-Out Cone Insulation Materials Ceramic Fiber Module/Uni-Felt

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords