HZS75 Concrete Batching Plant / ISO & CE

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 5 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

The product is widely used in key projects like various highways, railroads, high-speed railways, airports, ports, bridges, and hydropower stations, as well as commercial concrete mixing station, real estate, and municipal construction. With constantly increasing investment in technological innovation, the company has achieved great achievements and been recognized as “Provincial Enterprise Technology Center” in 2008. The company has 4 research department respectively specializing in mixing, transportation, conveying, and automation.

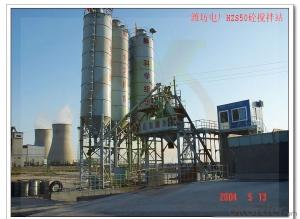

Concrete mixing plant HZS75

Theoretical productivity 75m3/h

Mixer model JS1500

Mixer nomination capacity 1500L

Mixing largest aggregate 80mm

Mixing motor power 2x30kw

Lifting motor power 22kw

Aggregate batcher PL2400

Aggregate bin capacity 3x15m3

Aggregate batching capacity 2400L

Aggregate types 3

Powder bin capacity 50/100/200t(选配)

Screw conveyor 50h

Aggregate measuring precision ±2%

Powder measuring precision ±1%

Water measuring precision ±1%

Additive measuring precision ±1%

Discharging height 3.8m

Power 110kw(without screw conveyor)

Weight 约46(without screw conveyor and cement bin)

Dimension depends on the configuration and equipment layout

- Q: Cement warehouse introduction, storage reserves?

- Cement silo in concrete mixing plant is mainly used for the storage of bulk cement, there are usually used 80 t, 100 t, 120 t, 150 t, etc., this is according to the size of the concrete mixing station or the user's production decision.

- Q: How much water does a concrete mixer use every day?

- It is also a waste of water to flush the transports. Suppose you flush a vehicle with 1-2t water, rinse it 2-3 times a day, and use 20 cars a day for a medium size of a blender, 40 to 120 t a day. From this perspective, the reuse of washing water is very conducive to environmental protection and water conservation. The rational recycling of water in the mixing stations is also gradually being promoted. Our new hydraulic patent product concrete wastewater and sewage circulation recycling used by many domestic manufacturers, most of new mixing plant began to use the recycling equipment. The wastewater recovery system has made some efforts for the environmental cause of China.

- Q: How to choose a good concrete mixer station?

- For simple concrete mixup stations, the overall cost of equipment is much cheaper, because the configuration is different and a lot of configuration is eliminated. But cement weighing cannot save configuration independent water weighing measurement more accurate to efficient, do not use water weighing system can also be mixing concrete, but there is a big hidden trouble. The water weighing system is not suitable for individual water weighing system, and it can reduce the investment of a simple mixing station by about 7, 000 yuan. And shortcomings is not water in the mixing drum of the weighing system and water, time node device can be used to set the water within a certain time interval to churn, but increased water and forced concrete mixer mixing time, still can cause concrete model is not stable. Therefore, although do not use water weighing system can save investment, but will increase the mixing time of concrete and affect the stability of the concrete, so the customer can choose according to oneself circumstance.

- Q: What does HZS mean in the HZS120 concrete mixing station

- HZS refers to the production capacity per hour. The specifications of the mixing plant size is named according to the theory of production per hour, the specifications of the commonly used at present in our country are: HZS25, HZS35, HZS50, HZS60, HZS75, HZS90, HZS120, HZS150, HZS180, HZS240 etc. Such as: HZS25 refers to the production capacity of 25 cubic meters per hour mixing station, the host for the double shaft mixer. If the host to use single model for HZD25 horizontal spindle

- Q: What are the ingredients for the concrete mixing stations?

- Start with the glue: cement, coal ash, mineral powder, and various expansions! Sand: natural sand, mineral sand, fine sand; Stone: 5-10, 5-20 water reducer! And tap water

- Q: What chemical materials are used in the concrete mixing station?

- It is the raw materials for the concrete mixers, the sand, stone, cement, fly ash, mineral powder, various admixtures, water, basically these seven raw materials

- Q: What is the difference between a concrete mixer and a concrete mixer

- The simple point is: the bones of the mixing tower are on top, and the bone is measured directly into the blender. The bone material of the stirring station is below, and the bone material is measured and then transported into the blender after the slanting belt. In a popular way, it is called the building, which is called the second ascent. Higher initial investment mixing floor production line 400000 station, because of mixing building bin above, therefore the steel structure will be bigger, inclined belt will be relatively longer. But in productivity, the churn is about 20 per cent more productive. In the operation, the energy consumption and the failure rate will increase due to the frequent start of the inclined belt of the mixing station, while the mixing building will be relatively low. Of course, in appearance, the mixing building is a bit more imposing than a mixer-stand, which can sometimes have an unexpected effect on the business. In addition, there are some technology mixing buildings that can be used, and the mixing stations can't be used, because the equipment is different. It's worth noting that the difference between the initial and the mixing stations is not absolute.

- Q: Concrete mixstations belong to no special equipment

- Special equipment is referred for life safety, greater danger of boilers, pressure vessels (including gas cylinders, hereinafter the same), pressure pipes, elevators, lifting machinery, passenger ropeway, large-scale amusement facilities. The boiler, pressure vessel (air bottle), pressure vessel is the pressure type special equipment; Elevator, hoisting machinery, passenger rope and large amusement facilities are special equipment for mechanical and electrical equipment.

- Q: What is the daily routine of the concrete mixing station?

- Concrete mixing station is made by mixing console, materials weighing system, material conveying system, material storage system, control system of five systems and other ancillary facilities of building materials manufacturing equipment, the main principle of work is with cement as cementing material, mixing materials such as sandstone, limestone, coal cinder stirring, finally made into concrete, as the wall materials into construction operation.

- Q: Does the concrete mixing station name have the name of the businessman concrete

- Yes, the general commodity concrete mixing station will write like this, the benefit of writing is simple and convenient, because the concrete three words are really too complicated! Zhengzhou zhengchen industrial production commodity concrete mixing station equipment.

Send your message to us

HZS75 Concrete Batching Plant / ISO & CE

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 5 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords