HZS60 Concrete Batching Plant / ISO & CE

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 5 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

The product is widely used in key projects like various highways, railroads, high-speed railways, airports, ports, bridges, and hydropower stations, as well as commercial concrete mixing station, real estate, and municipal construction. With constantly increasing investment in technological innovation, the company has achieved great achievements and been recognized as “Provincial Enterprise Technology Center” in 2008. The company has 4 research department respectively specializing in mixing, transportation, conveying, and automation.

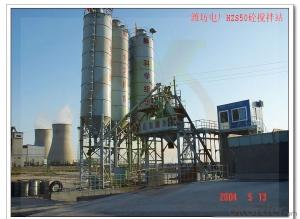

Concrete mixing plant HZS60

Theoretical productivity 60m3/h

Mixer model JS1000

Mixer nomination capacity 1000L

Mixing largest aggregate 80mm

Mixing motor power 2x18.5kw

Aggregate lifting belt motor power 15kw

Aggregate conveying belt width 650mm Side trough belt

Aggregate lifting belt conveying capacity 350t/h

Aggregate batcher PL2400

Aggregate bin capacity 3x12m3

Aggregate batching capacity 2400L

Aggregate types 3

Powder bin capacity 50/100t(Optional)

Screw conveyor 35t/h

Aggregate measuring precision ±2%

Powder measuring precision ±1%

Water measuring precision ±1%

Additive measuring precision ±1%

Discharging height 3.8m

Power 100kw(Without screw conveyor)

Weight 50t(Without screw conveyor and cement bin)

Dimension Depends on the configuration and equipment layout

- Q: What raw materials and equipment do you need for your own admixture?

- Admixtures seem simple, but they are actually a practical science. You want to get the ideal admixtures from the books or the web, "that's quite", and you're in the concrete mixing station. The concrete cost control of the mixing station is relatively strict, and the performance of the admixture is different

- Q: What is the concrete of the mixing station?

- What else can you do to sell concrete What is the station

- Q: What type of concrete mixer is needed for each hour of concrete 90 cubic meters?

- If it's a theoretical one, it's going to build 90 lines per hour, which is 90 square hours per hour, and if it's actually 90 square, it's going to be at least 120 stations.

- Q: What is the concept of on-site concrete mixer station

- The concrete mixing station is at the construction site to set up a soil mixing concrete equipment, including automatic conveying equipment, measuring equipment, concrete mixing equipment, cement storage warehouse etc.

- Q: How to choose a good concrete mixer station?

- Selection is best good survey is supply and demand situation of you and how many mixing station, concrete demand how, don't blindly pursuing big equipment, vehicles and personnel left unused, but it is now generally good, as long as the operation, mixing station not at a loss

- Q: What does HZS mean in the HZS120 concrete mixing station

- Because building aggregate measurement compared with standing aggregate metering, reduced the four of the intermediate links, and the vertical blanking metering, saved measuring time, thus greatly improving the production efficiency, under the condition of the same model, mixing building production efficiency than mixing plant production efficiency by a third. Such as: HLS90 floor of production efficiency and production efficiency of HZS120 stand HLS120 floor of production efficiency, production efficiency is equivalent to HZS180 stand HLS180 floor of the production efficiency is equivalent to the productivity of HZS240 station.

- Q: How long does it take to build a concrete mixer station?

- Normally, between one and three weeks. Plan the main points of the stirring station Venue: single 2m3, 3m3, the equipment occupies an area of about 21mx51m. Add in the yard, parking lot, road, office building, repair shop, recycling pool and so on, usually need the site 40mx80m (the land of 5 acres). 2m3 and 3m3 stations usually require 60mx80m (7.5 acres). If the location is more complex, the layout of the equipment should be based on the utilization of the site. To reduce the cost of future operations, it is suggested that there be a river at the edge of the site so that it can be used to carry sand stones. Distance should consider the best range of concrete delivery vehicles, not too far away from the main site, but also for future development. Optional: choose according to the expected amount of concrete. In a year of 300 working days, eight hours a day, the actual efficiency is lower than the nominal value given the various factors that are affected. Considering the requirement of the equipment for regular maintenance and maintenance, and the requirement of the high demand in some period, it is suggested that the equipment should be purchased. In some areas, the construction of new concrete and concrete stations must be at least two.

- Q: What are the advantages of HZS series of concrete mixing stations

- Is economical and practical type of small and medium sized concrete mixing station mixing plant, usually more than township, built in the smaller areas, compared with large mixing station the installed it easier, and covers an area of small, transportation is convenient.

- Q: What chemical materials are used in the concrete mixing station?

- Start with the glue: cement, coal ash, mineral powder, and various expansions! Sand: natural sand, mineral sand, fine sand; Stone: 5-10, 5-20 water reducer! And tap water

- Q: Concrete mixstations belong to no special equipment

- Special equipment is referred for life safety, greater danger of boilers, pressure vessels (including gas cylinders, hereinafter the same), pressure pipes, elevators, lifting machinery, passenger ropeway, large-scale amusement facilities. The boiler, pressure vessel (air bottle), pressure vessel is the pressure type special equipment; Elevator, hoisting machinery, passenger rope and large amusement facilities are special equipment for mechanical and electrical equipment.

Send your message to us

HZS60 Concrete Batching Plant / ISO & CE

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 5 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords