Hydraulic Vehicle-Ride Bridge,Dedicate Equipment

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

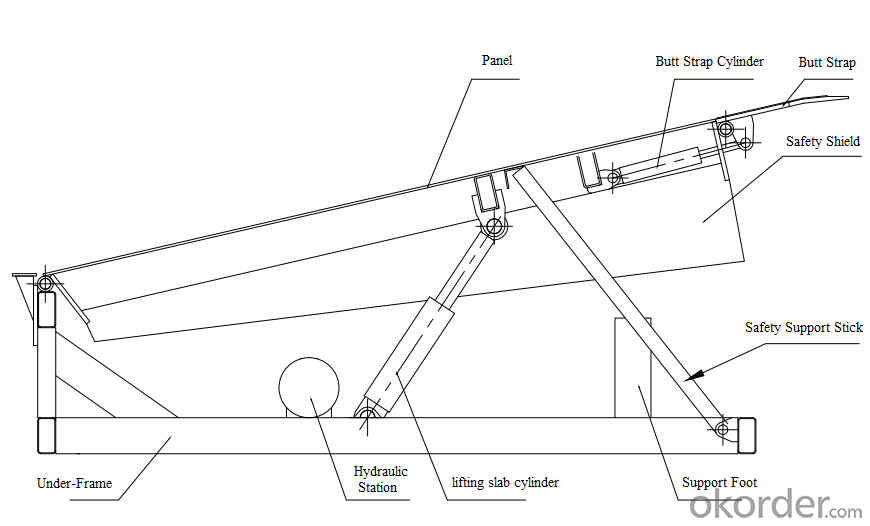

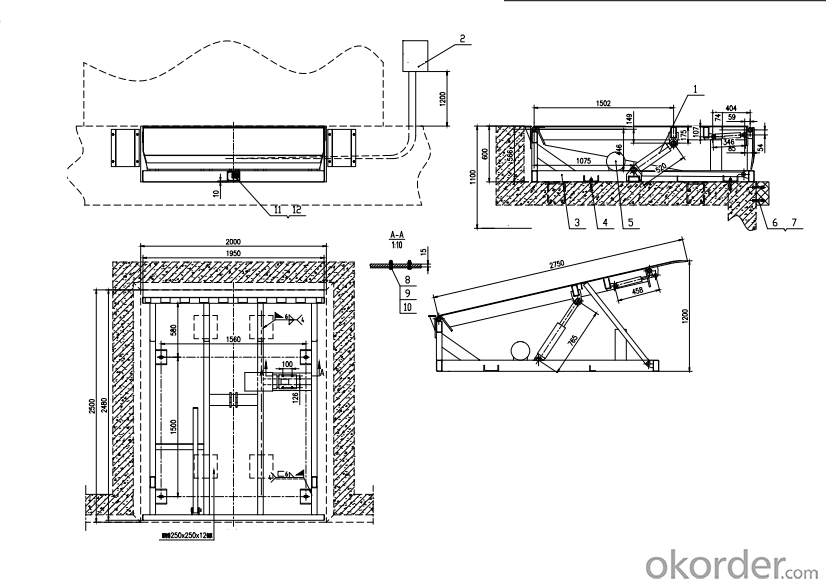

Main Structure

The fixed hydraulic bridge is mainly composed of butt strap, panel, under-frame, safety shield, support foot, lifting plate cylinder, connecting plate cylinder, electric control box and hydraulic station.

Operation

-First of all, the car tail door opens tightly locked on both sides of the car, and then the car back to the vehicle bridge pit where the both sides has the crash pad, and brake the car.

-The power switch of the electric control box is closed, and there are two methods of operation: cabinet control operation and remote control operation.

-When the selector switch is in the cabinet control state, press the rising button of the cabinet control, the motor of the oil pump rotates, and the running indicator light is lighted. The boarding bridge panel is slowly rising, up to the maximum height, the front plate began to stretch out, when the slab and panel up to the same level, press the down button control panel and cabinet, the slab decreased slowly in the same plane, a slab falls in the rear of the car compartment on the bottom surface, should not overlap less than 200mm.

-When the selector switch is in the remote control state, the remote control indicator lights up. Start the remote control, press the remote control to rise, oil pump motor, operation indicator light, the panel of the fixed hydraulic bridge is slowly rising, up to the maximum height, front slab of the fixed hydraulic bridge began to stretch out, slab and panel up to the same level, press the remote control button down, panel and the landing plate fall slowly in the same plane, and the slab is attached to the bottom of the car rear compartment. The overlap shall be no less than 200mm.

-After the work finished, press the cabinet control (remote control) rise button, the panel and the plate together rise, the car drives away, press the cabinet control (remote control) decline button, the panel automatically fall back, take the plate back.

-Cut off the main switch of power supply.

1. Butt Strap

2.Butt Strap Cylinder

3.Panel

4.Safety Shield

5.Safety Support Stick

6.Support Foot

7.lifting slab cylinder

8.Hydraulic Station

9.Under-Frame

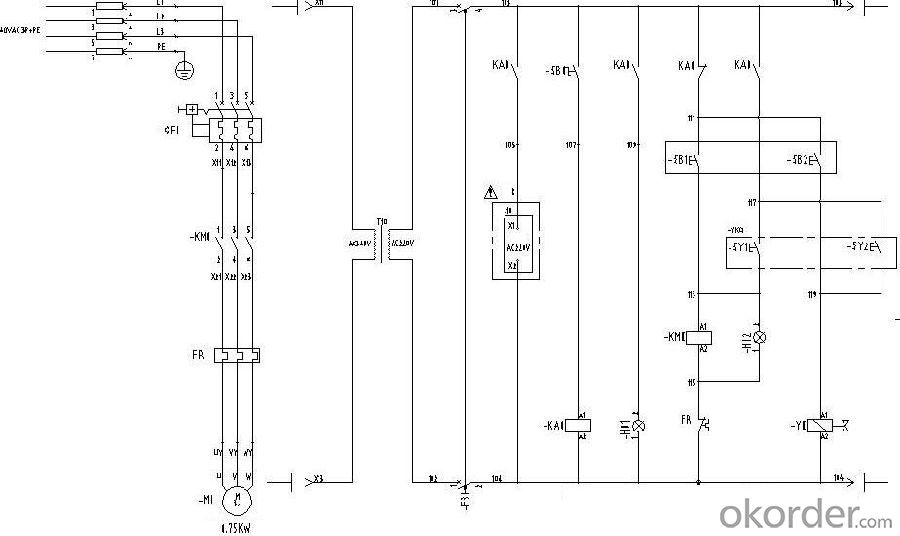

Schematic Diagram (SCH)

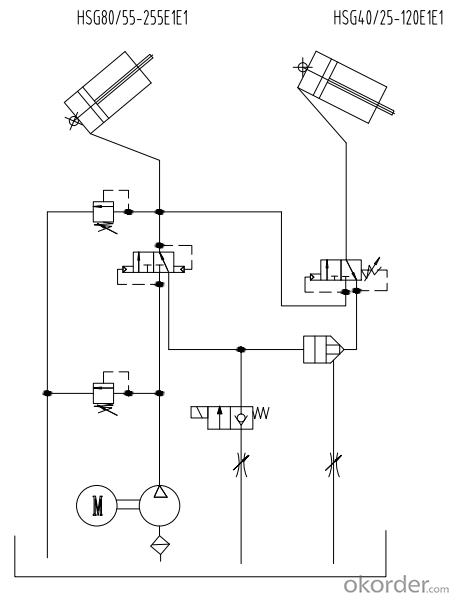

-Hydraulic Schematic Diagram

Safety Notice for Using

-Special personnel must be appointed for operation and maintenance the fixed hydraulic bridge, and the unskilled personnel should not operate without authorization.

-No personnel allowed work under the frame of the fixed hydraulic bridge or the side of the safety plate when the fixed hydraulic bridge is working, so as to avoid danger.

-The fixed hydraulic bridge is strictly prohibited to use overload.

-When the fixed hydraulic bridge is loading and unloading, it is forbidden to press the operation button.

-When the plate is extended, press the decline button immediately so as avoid more pressure to the cylinder for long time.

-In the process of work, if there is an abnormal situation, deal the trouble first and use it again, and not allowed to use it reluctantly.

-The safety support stick must be used correctly during maintenance.

-In the process of the fixed hydraulic bridge loading and unloading, the vehicle must be reliably braking and parking.

Maintenance

-Grease lubrication is often maintained at each rotation pin, use grease or oil every two months to ensure lubrication, reduce wear, and extend service life.

-The fixed hydraulic bridge uses anti abrasion hydraulic oil 46#, replaced for the first half of the year, then replaced once every year, and the oil tank must be cleaned when changing oil.

-Keep the foundation clean, the foreign matter what attached to each part should be removed in time, and there shall be no water in foundation.

-Check the fixed hydraulic bridge regularly every month, keynote to check the cracks in the welding position, the joint pin moves or not, the pin rings are loose or not, insurance stay bar is normal, the tubing damaged or aged, any loose oil leakage in each tubing joint, all power lines normal, any bad contacts in each control switch or button, etc. If the problem is found, it should be dealt with promptly.

-The damaged and detached paint should be repaired and painted in time to extend the service life of the fixed hydraulic bridge.

Technical Parameters

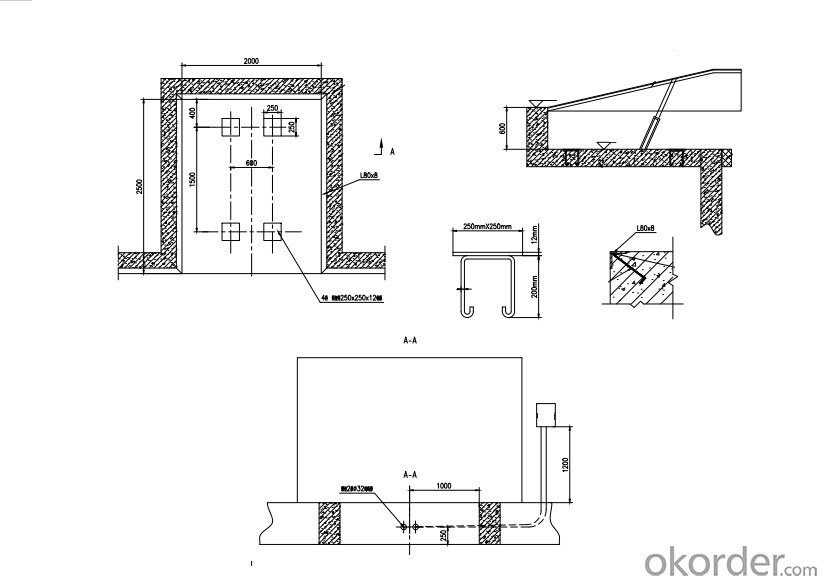

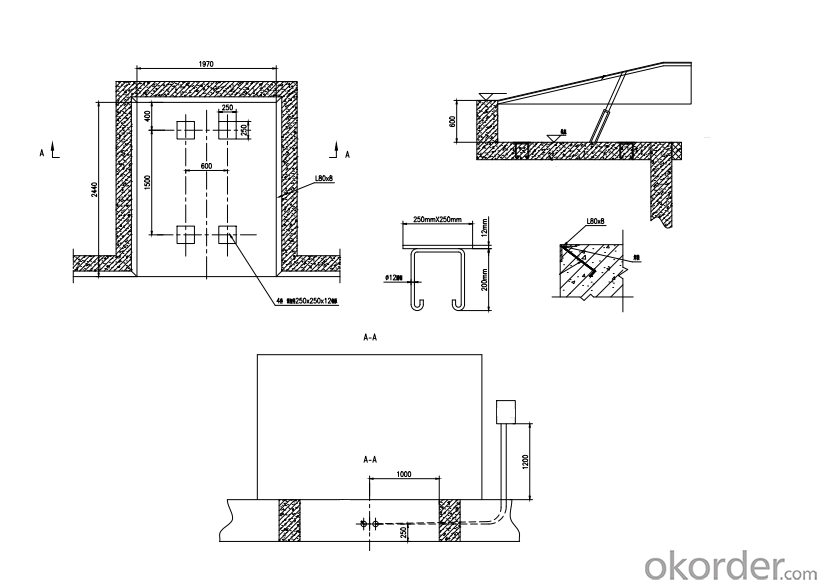

Table Slab:14mmSteel Plate + 3mm Checkered Plate

Table Frame:140*140*5 Square Tube

Under-Frame Material:60x120x5 Rectangular Tube

Deck Plate:8mm Checkered Plate

Hydraulic Oil Tube:High-Pressure Rubber Hose

Hydraulic Power Pack:YBZ-E2.7B4B82/1 0.75kw

Oil Cylinder Sealing Element:NOK (Japan)

Oiliness:Anti Abrasion Hydraulic Oil 46#

Oil Cylinder:Dia 80mm; Dia 40mm

Operating Mode:Cabinet Control + Remote Control(Taiwan YuDing)

Size of Saw-tooth Platform Bridge:L*W*H=2480mmx1950mmx600mm, Lifting Height 600mm.

Size of Flat Platform Bridge:L*W*H=2420mmx1920mmx600mm, Lifting Height 600mm.

Figure1. Saw-tooth Platform Bridge

Figure2. Pit Saw-tooth Platform Bridge

Figure3 Flat Platform Bridge

Send your message to us

Hydraulic Vehicle-Ride Bridge,Dedicate Equipment

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords