Household Food Packaging Aluminum Foil Manufacturer

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Household Food Packaging Aluminum Foil Manufacturer

1. Aluminum Foil Description

The production technologies and products performance of aluminum foil facing have been up to international advanced level. The aluminum foil facing products are mainly used for HVAC system, refrigerators, building thermal aluminum foil facing insulation and laminated with glass wool and rock wool to increase the insulation function.

• FSK aluminum foil facing is mainly used for duct wrap in HVAC system and other fields, such as vapor barrier etc., and suitable for off-line lamination of glass wool or rock wool. By special processing, the facing will have excellent flame retardant property.

• Heat-sealing aluminum foil facing is used for duct wrap without applying extra adhesive and suitable for online lamination of glass wool and rock wool.

• The WPSK aluminum foil facing, whose structure is white polypropylene/ fiberglass scrim/ kraft is mainly used for metal building insulation and suitable for the insulation of ware-house, factory, supermarket, office and so on.

• Double sided aluminum foil facing vapor barrier, whose structure is aluminum foil/ high strength kraft /fiberglass scrim /aluminum foil and laminated together by special flame retardant adhesive, can be used for roofing, wall insulation of house, warehouse, cold storages, factory and others.

2.Main Features of the Aluminum Foil

• Light weight

• High manufacturing accuracy

• High strength

• Small inertia resistance

• Strong heat dissipation ability

• Good visual effect

• High reflective insulation

• Heat resistant, water proof, stable at high temperature;

• environmentally friendly,no smell and not-toxic;

• Smooth and clear surface;

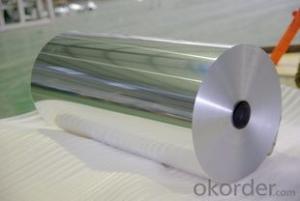

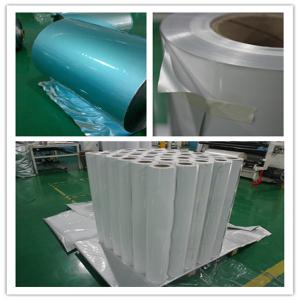

3.Aluminum Foil Facing Images

4.Aluminum Foil Facing Specification

TYPICAL PHYSICAL PROPERTIES:

Alloy | Temper | Thickness(mm) | Width(mm) | I.D.(mm) | O.D.(mm) | Thickness Tolerance(%) | Length | Lightness |

1050 | O | 0.01-0.3 | 300 | 76 | 500 | ≤5 | COIL | ≤60 |

1060 | O | 0.01-0.3 | 300 | 76 | 500 | ≤5 | COIL | ≤60 |

8011 | O | 0.01-0.3 | 300 | 76 | 500 | ≤5 | COIL | ≤60 |

5. Usage

Aluminium foil for household, food packing,Decoration,Beer lable,Food container,Milk cans,Bottle cap, Air-container,Cable,and ect.

6. FAQ

We have organized several common questions for our clients, may help you sincerely:

(1) How about your company?

A world class manufacturer & supplier of aluminum foil facing and is one of the large-scale professional investment aluminum foil facing bases in China. Annually more than 1000 containers of aluminum foil facing are exported to markets in Europe, America and Japan.

(2)What is the storage condition?

The products should be stored at room temperature and kept from wet and heat source.

It is essential, as with all pressure-sensitive tapes, that the surface to which the tape is applied must be clean, dry, and free of grease and oil.

The user should take test and do trial-application on the above products before coming into application so as to witness and ensure suitability for user’s special purpose and technique.

(3) How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

(4) How long can we receive the product after purchase?

In the purchase of product within four working days, we will arrange the factory delivery as soon as possible. The specific time of receiving is related to the state and position of customers. Commonly 7 to 10 working days can be served

- Q: For the first time, the microwave oven roast chicken wings, no use of aluminum foil, baked chicken wings can also get in, but the microwave oven is oil, the roast, bought a foil, but do not know how to use, is wrapped in chicken wings or on the grill, how much time temperature? Does the foil burn when the temperature is high? The first 4 minutes with no bake aluminum foil side, a total of 8 minutes OK!! I don't know how to use aluminum foil this time Headache...

- Hold it evenly and refrigerate for two hours.After the removal of each wing is uniform with cornstarch.Put the microwave oven on the grill for twelve minutes and turn over halfway.

- Q: What's the difference between aluminum foil composite and aluminum foil transfer? Thank you for being an expert

- The question is a little general. Aluminium foil compound, may be that our industry is in aluminum foil, aluminum foil with a polyurethane glue composite PET or PE film. Used to protect against electromagnetic shielding, signal shielding, radiation protection and so on. Such as the now popular pregnant women to wear radiation-proof clothes, there are components of aluminum foil.

- Q: What about the electromagnetic shielding effect of aluminum foil tape and copper foil tape?

- Electromagnetic shielding (electromagnetic shield) refers to the use of conductive materials made of ferromagnetic material or parts to shield the end of large capacity turbo generator stator core, in order to reduce the additional loss caused by the structure of the stator end winding leakage and local heating measures

- Q: When installing gas water heater in our house, the installation master will connect the aluminum foil smoke pipe directly to the smoke exhaust port of the machine, but the Internet says it can not be installed like this. What's wrong with this?

- Installation requirements:1, the installation of smoke pipes, the use of random equipped stainless steel smoke pipe, elbow.2, when the smoke pipe needs to be lengthened, priority should be given to the use of stainless steel smoke pipe or other corrosion resistance, high temperature resistance, fire resistance, no less than stainless steel metal smoke pipe. When no such pipe, can use high quality aluminum foil pipe is lengthened, but directly with the machine exhaust port connecting bend must use the elbow were equipped with, will never allow the use of aluminum foil and the smoke pipe is directly connected with the exhaust port machine.3. The outdoor part of the smoke pipe must be made of stainless steel smoke pipe which is randomly equipped. The aluminum foil pipe shall not be allowed to be extended directly outside.4, smoke exhaust pipe should be insulated from the ceiling more than 50mm.5, smoke pipe connections must be sealed with aluminum foil tape, and sealed tight, to prevent leakage of smoke.6, the smoke pipe extends outside the glass hole wall and the hole must be sealed, and extends outwards the smoke pipe should be down 3 degrees -5 degrees, the smoke pipe and the glass wall or clearance must be sealed to prevent water intrusion, gas flow.All the service personnel should install according to the requirements, otherwise, the headquarters will check the outlets in accordance with the non-standard installation and deal with the serious network breach and freeze the expenses.Below are typical correct installation plans. Be sure to pay attention to avoiding minefields!

- Q: What is a composite aluminum foil molded poly vinyl foam board, and what is a composite aluminum foil extrusion poly vinyl vinyl insulation board, the two how to distinguish?Please try to be more specific

- A kind of composite heat preservation board with aluminum foil is used in air conditioning and air duct insulation1, the insulation material molded type insulating materials used is moulded polystyrene foam board, also known as EPS, commonly used household appliances packaging materials is the white foam foam board; the extruded insulation material is extruded polystyrene foam board, which is XPS.

- Q: What is aluminum foil, please?

- Sheltering Mylar foil used in multi conductor wire control, such as electronic wire, computer wire, signal wire, coaxial cable, cable wire or cable network.

- Q: Do the aluminum foil used in the electric oven have the right and negative sides?

- In fact, aluminum foil is not only positive and negative sides, the reason why there is a gloss surface and matte surface distinction,Because the aluminum foil is in the manufacture process, is two, two manufacture.

- Q: Aluminum foil (aluminum foil) heat transfer of heat insulation is how, orThe old radiator looked black and looked uncomfortableA friend suggested wrapped with aluminum foil, has good heat dissipationOn the radiator, aluminum foil feel hot, not hot outHope to get your bachelor's scientific explanationThe foil blocking heat radiationThat is to say, tinfoil radiators (in the case of no gap) will affect the heat, huh

- Heat conduction is important, but for heating or air conditioning, the area of heat dissipation is more important, that is, the contact area between air and heat sink

- Q: Clamp aluminum foil paper with sticky?

- Delicious fish: 1.Wash, peel and cut the end of the water chestnuts;2. grass carp meat mince, add egg, salt, water chestnuts, little water, stir into a paste;3., letinous edodes washed, cut into pieces;4., pot boil with water, the fish pulp out of meatballs, one by one under the pot cooked, add letinous edodes tablets, salt, green onion, white pepper can be.

- Q: Can I use the foil instead of the baking paper?

- Depends on what to bake, baking paper is usually oil paper, there is anti sticking role

Send your message to us

Household Food Packaging Aluminum Foil Manufacturer

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords