Hot Spring Pipe High Pressure GRE Pipes and Fittings Equal Tee

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

API Hot Spring Pipe

1.Standard:API,ASTM,ISO,GB, etc

2.Anti-corrosion & high strength

3.Long service time

4.Low costs

GRE (Glass Reinforced Epoxy)

Some times, GRE and FRP/GRP (Fiber/Glass Reinforced Plastic) are regarded as the same

material with different names, but in most cases, since GRE choice epoxy resin as material,

it has stronger performances.

It is the thermosetting plastic products combining the reinforced material of fiberglass roving with the base material of epoxy resin.

It is made by mechanical filament wound process controlled by computer.

So it is a kind of composite material.

The GRE pipe offers a unique combination of chemical resistance, size stability, high strength, and thermal/electric non-conductivity.

So the GRE pipe can be used in the fields of chemical anti-corrosion, construction, electric insulation, power development etc.

Features:

1. Anti corrosion

2. High strength, more safety

3. More than 30 years service life

4. Light weight, easy installation and keeping cost

5. Flexible design and shorter reform term

6. No medium pollution

Technical Table

Applications:

1.Oil, petroleum, natural gas pipeline

2.Irrigation, hot spring, city water pipeline

3.Brine delivery pipeline

4.Other liquid transport pipeline

Strength:

1.High quality

We're state owned manufacturer with registered capital RMB 200 million specialized in this area.Standard:API-15HR,API-15LR,ISO9001,GB,etc.

2.Competitive price

Our raw material is from PPG SINOMA JINJING FIBERGLASS CO.,LTD, a JV enterprise

invested by our company and PPG industries to ensure high quality and low costs.

3.Great production capacity and short delivery time.We have 16 production lines for GRE pipe, with annual production capacity of 16000MT.

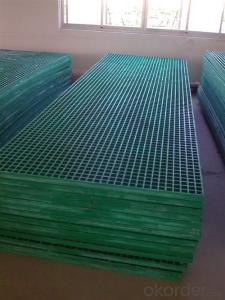

Pitcures of our factory:

FAQ of GRE pipes:

Q1: What’s the performance standards?

Lianzhong pipe is designed to meet all of these ASTM , AWWA, BS, DIN standards.

Q2: What’s the qualification testing for the products?

Lianzhong pipe has been rigorously tested to verify conformance to the ASTM D3262, ASTM D3517, AWWA C950 and DIN 16868 requirements

Q3: How long can I receive my goods?

A: Usually, we will deliver products within 20 days after the contract is signed. Delivery time is negotiable when necessary.

- Q: Designed to support FRP pipes, is it m or mm?

- Glass fiber reinforced plastic cable protection tube chemical composition: GRP winding pipe is a kind of glass fiber reinforced plastic product. With the continuous development of glass fiber reinforced plastic molding technology, FRP products have been widely used in various fields. FRP products have the advantages of light quality, high strength, corrosion resistance, long service life, flame retardant, high temperature resistance and various forms of products. Therefore, the industry gradually increase the use of glass fiber reinforced plastic products, which will be reinforced FRP mechanical properties and molding process put forward higher requirements. The forming process of FRP determines its shape, property and application prospect. The mechanical properties of glass fiber reinforced plastics determine whether their products can be widely used in industries with higher mechanical properties. Fiberglass reinforced plastic square tubes can replace some metal pipes used in industrial and civil fields, such as central air conditioning, chemical plants, etc. but glass fiber reinforced plastic square tube products are not common in the market. This is mainly due to the existence of poor strength, easy deformation and other defects.

- Q: Is the installation of FRP pipes required qualification?

- Generally speaking, the glass steel pipe manufacturers will be installed for shipyard workers training, but if the shipyard did not ask, the training goal is to allow workers to master the skills to install, but they do not grant workers qualification certificate, but some shipyard will require workers engaged in installation with the installation qualification, so manufacturers will end in training workers to master confirmation the installation skills of workers, awarded the class approved qualification certificate. I don't know. Are you clear about that?.

- Q: What kind of material is the pipe of the pipe that installs the pressure transmitter of GRP conduit? Is it fiberglass or carbon steel?

- This depends on what your medium is, the general food industry requires stainless steel, but the medium contains acidic substances, stainless steel is better than FRP corrosion resistance

- Q: What are the materials used in smoke exhaust pipes?

- In the production of the coal mine exhaust pipe is indispensable, in underground work, because from the ground, the air is not easy to reach, easy to accumulate large amounts of methane gas, these gases will need ventilation pipe timely transferred to the ground to prevent the explosion in the coal mine ventilation pipe, the material is generally iron and plastic.

- Q: How to repair and repair the broken hole of GRE glass fiber reinforced plastic pipe?

- Place an iron or glass piece of steel on a broken hole like a bicycle tire, then use three oil, two cloth, or five oil three cloth;

- Q: How to install FRP pipe correctly

- Glass tube and carbon steel pipe connection, at present, the most reliable way of connection is indeed onlyOther, such as on-site bonding, because of the two kinds of material is not the same, the quality of bonding is not very stable!

- Q: Glass fiber reinforced plastic pipeline to do anti-corrosion?

- Itself is a corrosion resistant material, no need for corrosion protection

- Q: How to connect glass fiber reinforced plastic sand pipe?

- The overall pressure test shall be carried out with reference to the code for construction and acceptance of water supply and drainage engineering pipes (GB50268-97), with a length of not exceeding 1000m for one section. Double "O" type sealing ring connection can bear the small foundation settlement change, this is the most prominent feature. Docking can be used for ground pipeline installation, can also be used to connect the underground pipeline of individual short, if more construction can meet the requirements of pipeline connection, some information that this connection is a flat end of life, is the use of epoxy resin and glass fiber cloth paste paste, the specific operation method is: first brush the connecting part in the pipeline for a layer of epoxy resin after pasting a layer of glass fiber cloth, flat interface paste length is generally about 500 mm, usually labeled with 5~6 paste layer layer is more solid, each layer of paste paste thickness should not be too large to be a layer of initial setting after a layer of paste. Flange connection line rigid connection, mainly used for connecting glass steel pipe and cast iron pipe, valves and other accessories, often used by glass steel bell and spigot size design, processing special steel bell and spigot connection.

- Q: How to prevent the glass fiber reinforced plastic pipe from being damaged by aging or over pressure, causing the liquid to splash and hurt people

- Can be in the pipeline within the glass fiber reinforced plastic, you can meet your requirements.

- Q: How can FRP tanks be connected to steel tubes?

- Field bonding process is usually provided by glass fiber reinforced plastic manufacturers, if there is no way, I can provide some experience for reference, there is little information, experience only.

Send your message to us

Hot Spring Pipe High Pressure GRE Pipes and Fittings Equal Tee

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords