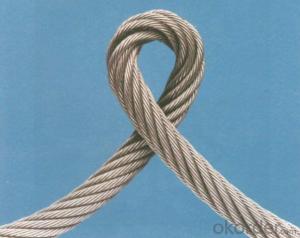

Hot sale types of steel wire rope 1*7 1*19 7*19

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

Steel Grade: steel wire rope

Standard: AISI, ASTM, BS, DIN, GB, JIS

- Type: Galvanized

Application: Construction

Alloy Or Not: Non-alloy

Packaging & Delivery

| Packaging Details: | in coil or as per your request |

|---|---|

| Delivery Detail: | 10-20days after confirm the order |

Specifications

Hot sale types of steel wire rope

1.size: 6*7 6*19 6*37 7*19 1*19

2.Standard : DIN ,BS, EN12385-4

3.Top quality ang best pric

Good quality steel wire rope, Hot sale types of steel wire rope 1*7 1*19 7*19

Welcome OEM order and inquiry.

1) standard:GB/T20118-2006,DIN,JIS and etc

2) construction: 1*19,6*19,7*19,6*7,7*7,6*12+7FC,6*37,6*24+7FC

3) diameter(mm):1.5mm-60mm

4) nominal tensile strength(Mpa):1570 1670 1770 1870 1960 2060

5) main application: verious equipment for derricking,elevator, lifting and drawing.

6) quality control: ABS,ISO9001,ISO14001

Specification of wire rope

STEEL WIRE ROPE | |||

Construction | Diameter | Type | Usage |

1*7 | 0.5~16mm | Steel wire rope | Marine |

1*12 | 1.0~30mm | General purpose wire rope | Running Rigging |

1*19 | 1.0~30mm | PVC wire rope | Fishing |

4*31 | 8.3mm | hot-dipped galvanized | Crane |

6*7 | 0.8~18mm | Galvanized steel wire rope | Hoist |

7*7 | 0.8~18mm | Wire rope sling | Oil Drilling |

6*12+7FC | 2~40mm | Elevator wire rope | General Engineering purpose |

6*19+FC(IWR) | 2.0~60mm | Stainless steel wire rope | Automobile Control cable,Ocean, Construction,Aircraft,Decoration ,etc |

6*19+FC(IWRC) | 3.0~60mm |

| |

6*24+7FC | 8.0~40mm | ||

6*37+FC(IWR, IWRC) | 6.0~120mm | ||

6*36 | 6.0~120mm | ||

8*19S+FC | 6~16mm | ||

8*19w+FC (IWR) | 6~16mm | ||

6*25Fi+FC | 6~35mm | ||

18*7+FC | 3~36mm | ||

34*7+FC(IWR, IWS) | |||

- Q: What are the different types of steel wire rod surface cleaning methods for wire drawing?

- There are several different types of steel wire rod surface cleaning methods that are commonly used in the wire drawing process. These methods are essential for removing any impurities or contaminants from the surface of the wire rod, ensuring a smooth and high-quality finished product. 1. Acid Pickling: Acid pickling is one of the most widely used methods for cleaning steel wire rod surfaces. This process involves immersing the wire rod in a bath of acid, typically hydrochloric acid, which helps to remove any rust, scale, or oxide layers. Acid pickling is effective in removing surface impurities and provides a clean surface for subsequent wire drawing processes. 2. Electrolytic Cleaning: Electrolytic cleaning is another commonly used method for removing contaminants from steel wire rod surfaces. In this process, an electric current is passed through the wire rod immersed in an electrolytic solution. The current causes the contaminants to dissolve and separate from the surface of the wire rod. Electrolytic cleaning can effectively remove oils, greases, and other organic substances from the wire rod surface. 3. Mechanical Cleaning: Mechanical cleaning methods involve the use of abrasive materials or brushes to physically scrub and clean the surface of the wire rod. This process can be done manually or using specialized machinery. Mechanical cleaning is effective in removing stubborn dirt, rust, or scale from the wire rod surface. 4. Shot Blasting: Shot blasting is a process that involves propelling small metallic or non-metallic particles against the wire rod surface at high speeds. The impact of the particles helps to remove any surface contaminants, scale, or rust. Shot blasting is particularly useful for cleaning wire rods with intricate shapes or hard-to-reach areas. 5. Ultrasonic Cleaning: Ultrasonic cleaning utilizes high-frequency sound waves to create tiny bubbles in a cleaning solution. The bubbles collapse upon contact with the wire rod surface, creating a scrubbing action that helps to remove contaminants. Ultrasonic cleaning is effective in removing fine particles, oils, and greases from the wire rod surface. Each of these steel wire rod surface cleaning methods has its advantages and limitations, and the choice of method depends on factors such as the type of contaminants, wire rod composition, and desired cleanliness level. The selection of the appropriate cleaning method is crucial to ensure optimal wire drawing performance and the production of high-quality wire products.

- Q: What are the main factors affecting the market forecasts of steel wire rod?

- The main factors affecting the market forecasts of steel wire rod include global economic conditions, demand and supply dynamics, raw material prices, government policies and regulations, technological advancements, competition within the industry, and geopolitical factors.

- Q: How is steel wire rod processed for subsequent applications?

- Steel wire rod is processed for subsequent applications through a series of steps that involve cleaning, heating, rolling, and cooling. The wire rod is first cleaned to remove any impurities and then heated to the desired temperature for easy shaping. It is then passed through a series of rolling mills to reduce its diameter and increase its length. Finally, the wire rod is cooled and coiled into spools or cut into desired lengths, ready for various applications such as construction, automotive, or manufacturing industries.

- Q: What are the common manufacturing defects in steel wire rod?

- Common manufacturing defects in steel wire rod include surface defects such as scratches, pits, and grooves, as well as internal defects like cracks, inclusions, and segregation. Other defects may include improper dimensions, excessive or insufficient coil weight, and improper surface finish.

- Q: What are the common forming techniques used for steel wire rod?

- The common forming techniques used for steel wire rod include drawing, rolling, and extrusion.

- Q: What are the different types of steel wire rod surface treatment chemicals?

- There are several different types of steel wire rod surface treatment chemicals that are commonly used in various industries. These chemicals are designed to enhance the properties of the steel wire rod and provide protection against corrosion. Some of the most common types of surface treatment chemicals include: 1. Phosphating chemicals: Phosphating is a common surface treatment process that involves the application of a phosphate coating to the steel wire rod. This coating helps improve the adhesion of paints and other coatings, provides corrosion resistance, and enhances the overall appearance of the wire rod. 2. Pickling chemicals: Pickling is a process that involves the removal of scale and oxides from the surface of the steel wire rod. Pickling chemicals, such as hydrochloric acid or sulfuric acid, are used to dissolve these impurities and leave a clean and smooth surface. 3. Passivation chemicals: Passivation is a chemical process used to remove free iron or iron oxide from the surface of the steel wire rod. This helps to enhance the corrosion resistance of the wire rod by creating a protective oxide layer. 4. Chromate conversion coatings: Chromate conversion coatings are often used as a post-treatment for phosphating or pickling processes. These coatings provide additional corrosion resistance and improve the adhesion of paints or other coatings. 5. Anti-corrosion oils: Anti-corrosion oils are applied to the surface of the steel wire rod to provide temporary protection against corrosion during storage or transportation. These oils form a thin film that helps to prevent moisture and other corrosive substances from reaching the surface of the wire rod. It is important to note that the choice of surface treatment chemical depends on the specific requirements of the steel wire rod and the intended application. Different industries may have their own unique set of requirements and may use different types of surface treatment chemicals accordingly.

- Q: What are the factors that influence the cost of steel wire rod?

- There are several factors that influence the cost of steel wire rod. These factors include the price of raw materials such as iron ore and other alloys, the cost of energy and transportation, market demand and supply dynamics, import and export tariffs, currency exchange rates, and any government regulations or policies affecting the steel industry. Additionally, factors such as production efficiency, economies of scale, and competition among steel manufacturers can also impact the cost of steel wire rod.

- Q: How is steel wire rod tested for resistance to atmospheric corrosion?

- Steel wire rods are tested for resistance to atmospheric corrosion using various methods. One common approach is the salt spray test, where the wire rods are exposed to a saltwater mist in a controlled environment. The rods are then observed for any signs of corrosion or rust formation. Additionally, accelerated corrosion tests may be conducted by subjecting the wire rods to high humidity and elevated temperatures to simulate harsh atmospheric conditions. These tests help determine the durability and corrosion resistance of the steel wire rods in different atmospheric environments.

- Q: What are the different types of steel wire rod surface cleaning methods for wire drawing?

- There are several types of steel wire rod surface cleaning methods for wire drawing. These include mechanical cleaning, chemical cleaning, and electrolytic cleaning. Mechanical cleaning involves the use of brushes, abrasive pads, or shot blasting to remove dirt, rust, and scale from the surface of the wire rod. Chemical cleaning involves the use of acids or alkaline solutions to remove contaminants and oxide layers from the surface. Electrolytic cleaning uses an electric current to dissolve and remove impurities from the wire rod surface. Each method has its advantages and suitability depending on the specific requirements of the wire drawing process.

- Q: What are the main factors influencing the choice of steel wire rod customer service?

- There are several main factors that influence the choice of steel wire rod customer service. Firstly, the quality of the customer service provided plays a crucial role. Customers value prompt and efficient responses to their inquiries and concerns. If a steel wire rod company can offer quick and helpful assistance to customers, it enhances their overall experience and satisfaction. Secondly, the expertise and knowledge of the customer service representatives are important factors. Customers often have technical questions or require guidance on specific products or applications. Therefore, having well-trained and knowledgeable staff who can provide accurate information and guidance is highly valued by customers. Additionally, the availability and accessibility of customer service are significant considerations. Customers expect to have various channels to reach out for assistance, such as phone, email, or live chat. Having a responsive customer service team that is available during regular business hours or even around the clock is preferred by customers who may have urgent or time-sensitive needs. Furthermore, the responsiveness and effectiveness of issue resolution are key factors in customer service choice. Customers appreciate when their concerns or problems are addressed in a timely manner and resolved to their satisfaction. A steel wire rod company that can quickly and effectively address customer issues builds trust and loyalty. Lastly, the overall reputation and reliability of the steel wire rod company also influence the choice of customer service. Customers often rely on word-of-mouth recommendations or online reviews to assess the reputation of a company's customer service. If a company has a positive track record of providing excellent customer service, it increases the likelihood of customers choosing their products. In conclusion, the main factors influencing the choice of steel wire rod customer service include the quality of service, expertise of representatives, availability and accessibility, responsiveness and issue resolution, as well as the reputation and reliability of the company. By considering these factors, customers can make informed decisions about which steel wire rod company to choose based on the level of customer service they provide.

Send your message to us

Hot sale types of steel wire rope 1*7 1*19 7*19

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords