Hot Sale Smart Cement Semi Trailer with Good Quality

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

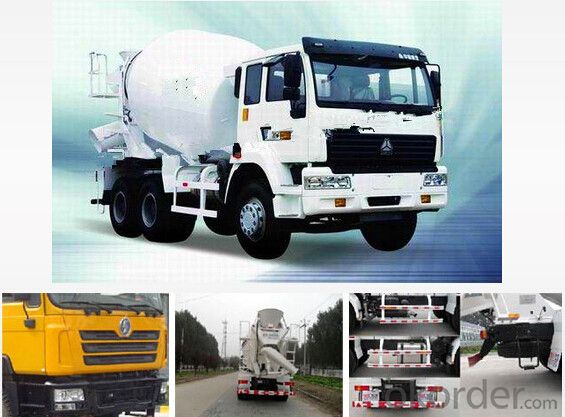

Product Name: Hot Sale Smart Cement Semi Trailer with Good Quality

1. Specification

Model: ZJV9409GFLLY | |

Overall size (mm) | 12991(L)*2500(W)*3995 (H) |

Wheel base (mm) | 8168+1310+1310 |

Tread (mm) | 1850 |

Kerb mass(Kg) | 11610 |

Min. turning diameter(m) | 24 |

Min. ground clearance | 360 |

Main configuration parameters | |

Axles | Fuhua brand,16T , 3 axles |

Towing pin | Baohua brand, 50mm or 90mm |

suspension | Leaf spring suspension |

tyre | 12.00R20, 12+1 |

Brake system | dual circuit, drum brake, air drive with ABS |

ABS | 4S/2M |

Tank body parameter | |

Tank actual volume��m3�� | 58 |

Tank actual dimension(mm) | 12040*2500 |

Unloading speed | More than or equal to 1.2m3/min |

Discharge residue rate | Less than 0.3% |

Rated pressure(Mpa) | 0.2 |

Tank mouth | Two compartment with two tank mouth |

Air compressor | 10.0m³/min |

Diesel engine | Weichai 4100 |

2. Application

Cement semi trailer

3. Package

Put into containers.

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products have its ISO certifications, adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 10 to 30 workdays.

Q4: If we can produce Hot Sale Smart Cement Semi Trailer with Good Quality according to customers request?

A4: Yes, we can produce Hot Sale Smart Cement Semi Trailer with Good Quality according to the difference country situations to make it suitable to the market and customers. We have very professional technical team to make the design.

Q5: How to make a quick resolution for after service?

A5: We have overseas branches all-around of world, If needed, the seller shall dispatch 2 engineers to the buyer's site for supervision of training. The buyer shall make available of necessary facilities &skilled personnel at site for training.

- Q: What is the normal speed in the transportation of the concrete mixer

- 12 square concrete mixer, 6 * 4 maximum wheelbase can be installed 12 square 14 square, must use 8 * 4 chassis (don't want to type to copy a bit!) ! Note: 1, the mixer has a low gear, and the novice should pay attention. No more than 30 yards for the car turning. The car itself is in control. 3, pay attention to the car. You must get out of your car to see the road, otherwise you will be miserable. 4, 24 hours to the sleepy at night, but must put the material to the site after finishing Can have a rest. On the way or captain will drive to you ha ha! I am ~, Other things like the road should be familiar, the road is the most important.

- Q: The concrete mixer transporter is running continuously for no more than one hour

- Whether this is a self-mixing concrete car, or the amount of the addition of a moderator, and weather factors.

- Q: How does the concrete mixing truck work?

- The concrete mixing truck consists of the chassis of the car and the concrete mixer. The chassis of the concrete mixer truck manufactured in our country is adopted by the car manufacturer. Its special purpose mechanism mainly includes the force of the force, the machine, the machine, the machine, the hydraulic system, the mixer, the cleaning system and so on.

- Q: s the collapse of four concrete mixer trucks

- The degree of slump refers to the ease of concrete, which is specifically to ensure the normal operation of the construction, including the water retention, liquidity and cohesion of the concrete. Workability is refers to the concrete mixture is easy to operation, mixing, transportation, pouring and tamping), and uniform quality, compacted concrete performance. It is a comprehensive technical property, including water retention, liquidity and cohesion. The main factors of influence and ease are the water usage, the ratio of water ash ratio, the ratio of sand, including the variety of cement, aggregate condition, time and temperature, admixture and so on.

- Q: How did the concrete agitate the concrete

- When pouring into the mixing building, the two sides of the car are equal to the stirring bracket, and the first time the mouth is made a mark, so that the next time it will be successful!

- Q: How many cubic meters of concrete mixer transport vehicle

- Dongfeng 140 concrete mixer truck, dongfeng 145 concrete mixer truck, dongfeng 153 concrete mixer truck, dongfeng hercules concrete mixer truck, dongfeng tianlong build concrete mixer truck concrete mixers, liberation, steyr, concrete mixer truck concrete mixer truck, hongyan, Europe man special concrete mixer truck concrete mixers and other projects.

- Q: Does it affect the ease of mixing too long?

- First, the quality is stable and controllable Second, there is less pollution of the environment Three, the energy conservation The mixer is required for both shipping distance and mixing speed, a bit technical

- Q: How many cars do you have for a concrete tanker

- Now the concrete agitator truck is generally measured in the quantity of tank, usually from six square cans to 18 cans, and now it is commonly used in 10-15 cans.

- Q: What is the purpose of the concrete mixer

- The main purpose of the mixer is to transport concrete or slurry that is already in a concrete mixer to the construction site. Due to concrete truck mixer mixing tank is adjustable speed rotating stirring, so the concrete mixer truck transport can maximum guarantee stipulated in the delivery distance and time not segregation, coarse aggregate is not settling, maintain good workability; Mixed soil mixer is used for the construction of hybrid stations and large projects. Another concrete mixer is used for carrying water that can carry the same amount of concrete as the payload.

- Q: What is the difference between a concrete mixer and a tanker?

- A special truck used to transport construction concrete; Because of its appearance, it is also commonly referred to as the tian. These trucks are equipped with cylindrical agitating cylinders to carry mixed concrete. By the automobile chassis, mixing barrel, transmission system, water supply equipment, take full power and power, before and after the mixing drum support, deceleration machine, hydraulic transmission system, material in and out of the system, operating mechanism and other parts. Due to the technical bottleneck, the domestic mixer can be made from 3m to 8m cubic meters, and the four large parts of the volume are imported. Composition: type 2 chassis, drive system, hydraulic system, frame, mixing tank, feeding system, water supply system, operating system, ladder and so on. The top of the mixing tank is mounted on the rack, and the rear end is supported by two supporting wheels mounted behind the chassis.

Send your message to us

Hot Sale Smart Cement Semi Trailer with Good Quality

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords