Hot Rolled Steel Wire Rod SAE1008 for Wire and Nail

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

OKorder is offering Hot Rolled Steel Wire Rod SAE1008 for Wire and Nail at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to African, South American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Hot Rolled Steel Wire Rod SAE1008 for Wire and Nail are ideal for structural applications and are widely used in drawing, construction materials, machinery parts, construction for Houses, Bridges, Roads.

Product Advantages:

OKorder's Hot Rolled Steel Wire Rod SAE1008 for Wire and Nail are durable, strong, and wide variety of sizes.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Manufacture: Hot rolled

Grade: Q195 – 235

Certificates: ISO, SGS, BV, CIQ

Length: 6m – 12m, as per customer request

Packaging: Export packing, nude packing, bundled

Grade | Chemical Composition(%) | |||||

C | Mn | Si | S | P | B | |

SAE1006B | 0.03~O.07 | ≤0.32 | ≤0.30 | ≤0.045 | ≤0.040 | >0.0008 |

Mechanical properties | ||||||

Yield strength(N/mm2) | Tensile strength(N/mm2) | Elongation(%) | ||||

250-280 | 350-380 | ≥32 | ||||

Grade | Chemical Composition(%) | |||||

C | Mn | Si | S | P | B | |

SAE1008B | 0.10max | 0.3~O.50 | 0.15max | 0.050max | 0.040 max | 0.0008 min |

Mechanical properties | ||||||

Yield strength(N/mm2) | Tensile strength(N/mm2) | Elongation(%) | ||||

≥195 | 315-430 | ≥30 | ||||

Grade | Chemical Composition(%) | |||||

C | Mn | Si | S | P | B | |

Q195B | 0.06~O.12 | 0.25~O.50 | ≤0.30 | ≤0.050 | ≤0.045 | >0.0008 |

Mechanical properties | ||||||

Yield strength(N/mm2) | Tensile strength(N/mm2) | Elongation(%) | ||||

≥195 | 315-430 | ≥33 | ||||

Grade | Chemical Composition(%) | |||||

C | Mn | Si | S | P | B | |

Q235B | 0.12~O.2 | 0.3~O.701 | ≤0.30 | ≤0.045 | ≤0.045 | >0.0008 |

Mechanical properties | ||||||

Yield strength(N/mm2) | Tensile strength(N/mm2) | Elongation(%) | ||||

235 | 375-500 | ≥26 | ||||

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will arrange production. The normal sizes with the normal grade can be produced within one month. The specific shipping date is dependent upon international and government factors, the delivery to international main port about 45-60days.

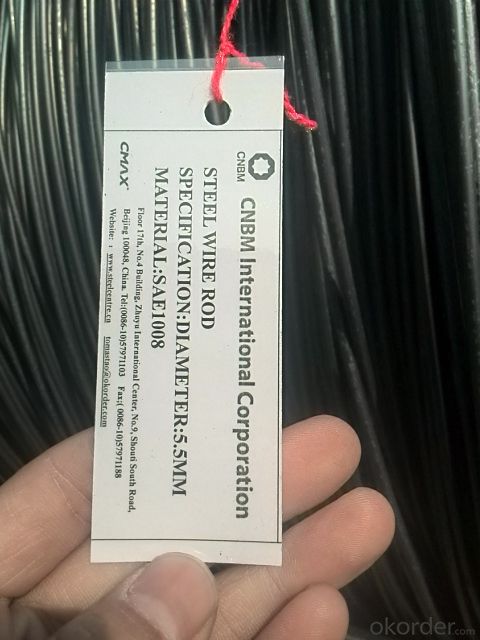

Images:

- Q: How is steel wire rod used in the production of wire mesh screens?

- Steel wire rod is used in the production of wire mesh screens as it serves as the primary material for creating the mesh itself. The wire rod is first drawn into the desired thickness and then woven or welded together to form the mesh pattern. This sturdy and durable steel wire rod ensures that the wire mesh screens can withstand various applications such as filtration, separation, and protection, making them ideal for use in industries like construction, mining, and agriculture.

- Q: How is steel wire rod used in the manufacturing of wire ropes for elevators?

- The manufacturing of wire ropes for elevators heavily relies on steel wire rod, which acts as a crucial element. It serves as the main material for shaping the individual strands that compose the wire rope. The steel wire rod goes through a series of processes aimed at transforming it into a sturdy and long-lasting wire rope. To begin with, the steel wire rod is passed through a sequence of dies that reduce its diameter and increase its length. This process, known as wire drawing, guarantees that the wire rod attains the desired thickness and smoothness. Subsequently, a lubricant is applied to the drawn wire to enhance its flexibility and minimize friction. Following the wire drawing process, the steel wire rod is twisted and braided together to form the strands of the wire rope. These strands are arranged in a helical pattern around a central core, which provides additional strength and stability to the wire rope. Once the strands are shaped, they undergo compression and pressing to ensure maximum strength and durability. This compaction process eradicates any gaps between the individual strands and ensures a uniform distribution of load across the wire rope. The final step in the manufacturing process involves applying a protective coating to the wire rope to safeguard against corrosion and wear. This coating can be composed of materials like zinc or plastic, which further enhance the wire rope's longevity and reliability. In conclusion, steel wire rod holds a pivotal role in the manufacturing of wire ropes for elevators. It is utilized to create the individual strands that constitute the wire rope, which are then twisted, braided, and compacted to provide strength and flexibility. The resulting wire rope is an essential component in elevators, guaranteeing the safe and reliable transportation of people and goods.

- Q: What is the impact strength of steel wire rod?

- The impact strength of steel wire rod refers to its ability to withstand sudden shocks or blows without fracturing or breaking. It is typically high, making steel wire rod a durable and resilient material for various applications.

- Q: What are the common industry workshops for steel wire rod?

- Some common industry workshops for steel wire rod include wire drawing workshops, heat treatment workshops, surface treatment workshops, and inspection workshops.

- Q: How is steel wire rod manufactured in an electric arc furnace?

- Steel wire rod is manufactured using an electric arc furnace (EAF) through a series of steps. The process begins with the raw materials, which typically include iron ore, scrap metal, and carbon additives. These materials are carefully selected to ensure the desired chemical composition and quality of the steel wire rod. Firstly, the raw materials are charged into the electric arc furnace. The furnace is a large, refractory-lined vessel capable of withstanding extremely high temperatures. Once the furnace is charged, an electric current is passed through graphite electrodes that are positioned above the scrap metal and raw materials. As the electric current passes through the electrodes, it creates an electric arc that generates intense heat. This heat melts the raw materials and scrap metal, resulting in a molten pool of liquid steel. The temperature in the furnace can reach up to 3,000 degrees Celsius. Once the steel is melted, various refining processes are employed to remove impurities and adjust the chemical composition. Oxygen and other gases are injected into the furnace to remove carbon and other elements that need to be reduced. Alloying elements such as manganese, chromium, and nickel may also be added at this stage to achieve the desired properties of the final product. After the refining process, the molten steel is tapped from the furnace into a ladle, where it is further treated to remove any remaining impurities. The ladle is then transported to a continuous casting machine, where the molten steel is solidified into billets or blooms. The solidified billets or blooms are then transferred to a rolling mill, where they are heated and rolled into wire rod. The rolling process involves passing the billets or blooms through a series of rollers that gradually reduce their cross-sectional area, resulting in the desired wire rod dimensions. The wire rod is then cooled and coiled into large coils. Finally, the coiled wire rod is subjected to various finishing processes, such as surface cleaning, heat treatment, and surface coating, to enhance its quality and appearance. The finished wire rod is then ready for further processing, such as drawing, cold heading, or other applications in the steel industry.

- Q: What are the different welding processes used for steel wire rod?

- Some of the different welding processes used for steel wire rod include gas metal arc welding (GMAW), shielded metal arc welding (SMAW), gas tungsten arc welding (GTAW), and resistance spot welding (RSW). Each of these processes has its own advantages and is suited for specific applications in the steel wire rod industry.

- Q: How is the surface finish of steel wire rod determined?

- The surface finish of steel wire rod is determined through a combination of manufacturing processes and quality control measures. First, the steel wire rod is produced through a hot rolling process, where the steel is heated and passed through a series of rollers to achieve the desired shape and thickness. During this rolling process, the surface of the steel wire rod can develop imperfections such as scale, which is a layer of oxide that forms on the surface due to the high temperatures involved. To remove this scale and improve the surface finish, the steel wire rod may undergo a descaling process, which involves methods like acid pickling or mechanical descaling. After descaling, the steel wire rod may undergo further processes like cold drawing or heat treatment to achieve the desired mechanical properties. These additional processes can also contribute to improving the surface finish of the steel wire rod. To ensure the desired surface finish is achieved, quality control measures are implemented throughout the manufacturing process. This includes regular inspections and testing of the steel wire rod to detect any surface defects or imperfections. Various techniques such as visual inspection, ultrasonic testing, and surface profilometry can be used to evaluate the surface finish and ensure it meets the required standards. In conclusion, the surface finish of steel wire rod is determined through a combination of manufacturing processes such as rolling, descaling, cold drawing, and heat treatment. Quality control measures are also implemented to inspect and test the surface finish, ensuring it meets the desired standards.

- Q: What are the common production processes for alloy steel wire rod?

- The common production processes for alloy steel wire rod include melting and refining the raw materials, continuous casting to form a solid billet, hot rolling the billet into wire rod, followed by cooling, surface treatment, and final inspection and packaging.

- Q: What are the different types of wire drawing processes used for steel wire rod?

- There are several different types of wire drawing processes that are commonly used for steel wire rod. These processes include: 1. Pointing: This process involves reducing the diameter of the wire rod by passing it through a series of dies. The wire rod is pulled through the dies, which gradually decrease in size, until the desired diameter is achieved. This process is typically used for smaller diameter wires. 2. Bull block: In this process, the wire rod is passed through a series of rotating cones or blocks. The cones have grooves that decrease in size, causing the wire rod to be reduced in diameter as it is pulled through. This process is commonly used for larger diameter wires. 3. Continuous rotary drawing: In this process, the wire rod is fed through a series of rotating dies. As the wire rod passes through the dies, it is gradually reduced in diameter. This process can be used for both small and large diameter wires. 4. Multi-pass drawing: This process involves passing the wire rod through a series of drawing dies in multiple stages. Each pass through the dies reduces the diameter of the wire rod. This process is often used for wires with very small diameters and requires multiple drawing stages to achieve the desired final diameter. 5. Tube drawing: This process is similar to wire drawing but is used to produce hollow tubes. The wire rod is pulled through a die with a mandrel inside, which helps to shape the wire rod into a tube. This process is commonly used for the production of seamless steel tubes. Overall, these different types of wire drawing processes provide manufacturers with various options for reducing the diameter of steel wire rod and producing wires of different sizes and shapes to meet specific requirements.

- Q: How is steel wire rod used in the manufacturing of wire for automotive fuel injection systems?

- Steel wire rod is used in the manufacturing of wire for automotive fuel injection systems as it provides the necessary strength and durability required for this critical application. The wire rod is first processed through various stages such as drawing and annealing to achieve the desired diameter, surface finish, and mechanical properties. This wire is then further processed and formed into intricate shapes and components, such as fuel injector springs, connectors, and terminals, which play a vital role in ensuring efficient fuel delivery and system performance.

Send your message to us

Hot Rolled Steel Wire Rod SAE1008 for Wire and Nail

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords