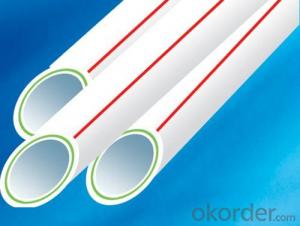

3 4 Inch Plastic Pipe Fittings for Drinking Water and Hot & Cold Water Pipes

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description of Products

Length: According to customer requirement

Thickness: SDR11/13.6/17

Standard: ISO

Color: many colors

Product name: Plastic Pipe

Application: house and garden

Usage: Family Decoration Industry

Certification: ISO Certificate

Feature: Lightweight

Size: Customized Size

Type: Round Pipe

Connection: Butt Fusion

Product Show

Specifications

1)Material:HYOSUNG R200P, Basell H5416

2)Size:20-160MM

3)Standard:DIN8077/8078

4)Pressure:PN10

Product Applications

Distribution for cool and hot water Duct for drinkable water system Pipes for kinds of high-temperature and low-temperature heating system Pipes for heating and cooling settings in solar energy system Connecting pipe for air conditioners

Product Advantages

1)100% excellent raw materials ,safe and hygeian .

2)Drinking water pipeline system.

3)Recyclable ,benefit to the environment

4)Resistance to abrasion and corrosion.

5)Connected by heating ,leakage prohibit

6)Long lifespan,Minimum 50 years life time at 60 or 70°C and 10 bar maximum pressure.

FAQ

Q1: How Can I Get a Sample?

A1: You can get samples by communicate with our export sales.

Q2: How Long Is Delivery?

A2: Delivery time will be30-45days according to order quantity.

Q3: What Is The MOQ?

A3: MOQ depends on different items.

Q4: What Is Our Normal Payments Terms?

A4: Our normal payment terms now is: T/T, L/C or western union, MoneyGram.

- Q: How do plastic pipe fittings compare to fiberglass fittings?

- Plastic pipe fittings are generally more affordable and readily available compared to fiberglass fittings. However, fiberglass fittings offer superior strength, durability, and resistance to corrosion and chemicals. They are also lightweight and have better thermal insulation properties. Ultimately, the choice between plastic and fiberglass fittings depends on the specific requirements and intended use of the fittings.

- Q: Can plastic pipe fittings be used in stormwater management systems?

- Yes, plastic pipe fittings can be used in stormwater management systems. Plastic fittings are commonly used in these systems due to their durability, corrosion resistance, and ease of installation. They are available in various sizes and configurations to meet the specific requirements of stormwater management projects.

- Q: Regarding the connection of plastic pipes and inspection wells, is the flexible connection or rigid connection?

- Connected with the manhole brick or concrete pipe or tube, the intermediate layer is connected with the outer surface approach, part of the advance with polyvinyl chloride adhesive in the pipe or pipe fittings with the wall made of coarse and intermediate layer, and then use the cement mortar wall built into the manhole;

- Q: Can plastic pipe fittings be used in vacuum systems?

- No, plastic pipe fittings are generally not suitable for use in vacuum systems as they may not be able to withstand the high levels of negative pressure and can potentially deform or fail under such conditions.

- Q: Can plastic pipe fittings be used for chemical reactors and tanks?

- No, plastic pipe fittings are not suitable for chemical reactors and tanks as they may not have the necessary resistance to withstand the corrosive nature of chemicals and could lead to leaks or failure.

- Q: Can plastic pipe fittings be used for pneumatic systems?

- Yes, plastic pipe fittings can be used for pneumatic systems. Plastic pipe fittings are lightweight, cost-effective, and resistant to corrosion, making them suitable for various applications, including pneumatic systems. However, it is important to ensure that the plastic fittings meet the required pressure and temperature ratings for the specific pneumatic system.

- Q: Are plastic pipe fittings resistant to earthquakes?

- Plastic pipe fittings can vary in their resistance to earthquakes depending on the specific material and design. Some plastic pipe fittings, like those made from high-density polyethylene (HDPE), can exhibit excellent flexibility and resilience, making them more resistant to seismic activity. However, it is crucial to consider other factors such as installation techniques, support systems, and overall system design to ensure the durability and safety of plastic pipe fittings during earthquakes.

- Q: Can plastic pipe fittings be used in renewable energy systems?

- Yes, plastic pipe fittings can be used in renewable energy systems. Plastic pipes and fittings are commonly used in various renewable energy applications such as solar water heaters, geothermal systems, and biomass heating systems. They offer advantages such as corrosion resistance, lightweight construction, and ease of installation, making them suitable for use in renewable energy systems.

- Q: Do plastic pipe fittings require any special testing or certification?

- Yes, plastic pipe fittings typically require special testing and certification to ensure they meet industry standards for performance, durability, and safety. This testing is necessary to ensure that the fittings can withstand various pressures, temperatures, and chemicals they may encounter during their intended use. Certification from recognized organizations or regulatory bodies confirms that the fittings have undergone rigorous testing and comply with relevant standards, providing assurance to customers and end-users.

- Q: Can plastic pipe fittings be used in fire escape systems?

- No, plastic pipe fittings are not recommended for use in fire escape systems. It is crucial to use fire-resistant materials such as steel or copper to ensure the safety and reliability of the system.

Send your message to us

3 4 Inch Plastic Pipe Fittings for Drinking Water and Hot & Cold Water Pipes

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords