Hot Dipped Galvanized Gabion Box Hexagonal Mesh

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 set

- Supply Capability:

- 5000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Description

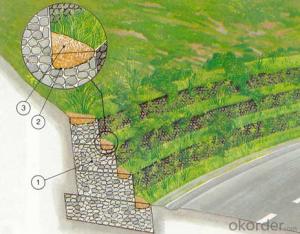

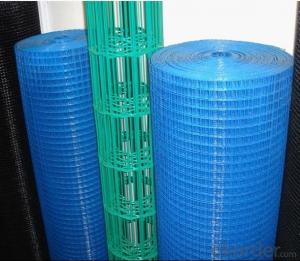

Heavy Hexagonal mesh Gabion is also called big specification hexagonal mesh or gabion mesh, it's made from high grade steel wire through twistion gand braiding by machine, it can be mainly used in supporting and protecting of side slope and basis pit. Mountain rock hanging mesh, green guard rail netting on side slope, railway guard rail netting, highway guard rail netting. Heavy hexagoanl mesh also can be worked into stone cage or stone cushion, and used in reservoir, river or dyke for closure.

| Mesh size (mm) | Wire diameter (metal wire) (mm) | Wire diameter(PVC materal wire)/inside diameter/ourside dia | The biggest breadt is vice (m) |

| 60x80 | Ø 2.0-2.8 | Ø 2.0/3.0-2.5/3.5 | 4.3 |

| 80x100 | Ø 2.0-3.2 | Ø 2.0/3.0-2.8/3.8 | 4.3 |

| 80x120 | Ø 2.0-3.2 | Ø 2.0/3.0-2.8/3.8 | 4.3 |

| 100x120 | Ø 2.0-3.4 | Ø 2.0/3.0-2.8/3.8 | 4.3 |

| 100x150 | Ø 2.0-3.4 | Ø 2.0/3.0-2.8/3.8 | 4.3 |

| 120x150 | Ø 2.0-4.0 | Ø 2.0/3.0-3.0/4.0 | 4.3 |

- Q: On the issue of their own screen printing

- Print a colored pattern on a white shirt, I'm now nothing I wanna know what i need ...

- Q: What is the process of the screen printing process?

- The screen has a flat weave, twill weave, semi-woven, all woven. White screen exposure easily lead to diffuse reflection, golden, red, amber absorption of ultraviolet light, can prevent halo

- Q: The difference between screen printing characteristics

- Not subject to the size and shape of the substrate restrictions can only be printed on the plane, and silk screen can not only print on the plane, but also in the special shape of the molding and convex surface printing, but also can print a variety of large

- Q: What is the commonly used mapping software for screen printing?

- the vector is based on geometric characteristics to draw graphics, the vector can be a point or a line, the vector can only rely on software generated, the file occupies less internal space, because this type of image file contains separate separate images, Free unlimited reorganization.

- Q: How to clean the screen plate

- greatly reducing the liquid consumption and cost, operating time Greatly reduced, the operating staff do not touch the liquid, will not hurt the human body.

- Q: Screen printing has several characteristics

- It is the most widely used screen printing in the stencil printing, and the screen printing is the use of silk fabrics, synthetic fiber fabrics or metal mesh stretched in the frame

- Q: Is the screen printing the best way? And other printing methods than it?

- Mass production, and is flat printing can be considered to contact gravure printing, but the plate cost is high

- Q: Screen printing ink firmness problem

- If not enough, it can only change solvent-based ink, the solvent ink tension is small, ink layer spread, drying speed, adhesion will be much better, but the volatile substances on the human body and the environment is harmful, and flammable and explosive, need

- Q: How to make screen printing layout smooth

- Paint the (pattern) paint, repeat it several times and check that the pattern is transparent. If the number of prints is not large, the back generally do not need to paint.

- Q: Screen printing and printing the difference

- Printing (Graphic Arts, also use Graphic Communications that is graphic transmission) is the text, pictures, photos, security and other originals by plate making,

Send your message to us

Hot Dipped Galvanized Gabion Box Hexagonal Mesh

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 set

- Supply Capability:

- 5000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords