Hooked Steel Fiber for Concrete High Strength

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 500000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hooked Steel Fiber for Concrete High Strength

Description:

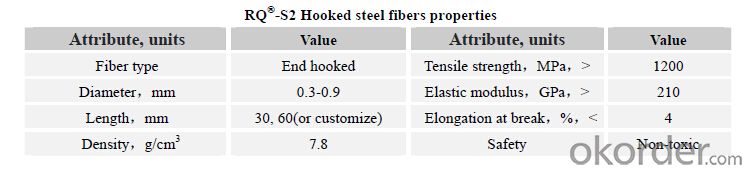

RQ®-S2 Hooked steel fibers are cold drawn steel wire fibers with hooked ends. Compared

with ordinary steel fibers, RQ®-S2 Hooked steel fiber reinforced concrete has more ductility and

high load bearing capacity. RQ®-S2 fibers can reduce expansion of micro-cracks due to plastic

shrinkage, drying shrinkage and thermal cracking efficaciously, and intercept the formation and

propagation of macro-cracks.

The main technical performance and characteristics:

Features:

High anchoring force. RQ®-S2 Hooked Steel Fibers can generate high anchoring force with cement-based

materials due to the hooked ends, two times more than ordinary steel fiber.

Excellent dispersion. RQ®-S2 Hooked Steel Fiber can get excellent dispersion in the concrete, and convenient

construction.

Obviously toughening effect. Adding RQ®-S2 Hooked Steel Fiber into concrete, the fiber improves the

toughness performance of concrete.

Significantly increased impact resistance. The impact resistance of RQ®-S2 Hooked Steel Fiber reinforced

concrete increases a lot compared to the plain concrete.

Reduce shrinkage and creep. Under sustained loading, Homogeneous distribution of steel fiber can reduce

expansion of micro-cracks and macro-cracks.

Usage and notes

Dosage: Common dosage of 39~156kg/m3 (corresponding to the volume dosage of 0.5~2%).

Material requirements: Sea water, sea sand and chloride must not be used in steel fiber reinforced concrete.

Mixing:The fiber, cement, sand, stone added in the mixer, add water and stir; mixing time should be extended to

ensure good fiber dispersion.

Curing: The steel fiber reinforced concrete (or cement) and common concrete (or cement) with the same

construction and curing process.

Safety in use: Appropriate protection should be taken in case of stabbing and splashing into the eyes.

Application range:

Widely used in the highway pavement, bridge, tunnel, industry floor, airport pavement, building structure,

underground engineering, underwater engineering, water-proof engineering, hydropower station, harbor pavement,

military engineering and all kinds of concrete prefabricated.

Packaging:

Paper package with 20kg/bag(or customized). The packages should be sealed in a cool and dry place. Waterproof

should be ensured during transportation. Shelf life is one year. Handling and transportation is very convenient.

FAQ

1.Q: What is MOQ?

A: Our MOQ is 1 TON.

2.Q: Could you offer free sample?

A: We can provide free samples to you for quality testing.

3.Q: What about your packing?

A: For liquid: Flexitank, or IBC tank 1000L

For powder:Woven fabric bag with plastic film liner( 25kg or 1000kg)

Clients’ packing is workable.

4.Q: How about your productive capacity?

A: 150000 tons/Year.

5.Q: What is your delivery time?

A: Within 7 days after received deposit or L/C at sight.

Send your message to us

Hooked Steel Fiber for Concrete High Strength

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 500000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords