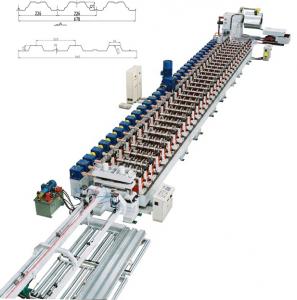

highway deck forming machine in different trypes

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 8 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

sandwich panel production line is to put the painted steel coil with strong adhesive after moulding compound on both sides of the thicker material inner core, formed a kind of high strength, light weight, heat insulation, durable good appearance of new building materials. Are widely used in light steel structure building roof and wall body, the product has bright color and without the characteristics of the secondary decoration.

sandwich panel production line adopts advanced production technology with gas, electricity,machinery into an organic whole, is a special mechanical equipment processing caigang insulation composite panels, working speed adopts frequency conversion stepless speed regulation, can one-time composite corrugated type composite panels, a full set of assembly line by the feeding mechanism, composite, coating, heating, edge, notching, whole side, pneumatic and automatic cutting), is the production of industrial workshop, warehouse roof panel and wall panel, such as the indispensable equipment.

Peremeters:

Electricity power: 380V/50-60HZ

Motor power:32kw

Production speed:0-4m/min

Product Width:1000mm 1200mm

Product thickness:50-250mm

Production ability:600000m2

Corrugated panel roll forming machine

Main Teachnical Parameters

1.Material thickness: 0.2-1.0mm

2.Feeding width: 900mm

3.Effective width: 760mm

4.Forming speed: 12-16m/min

5.Diameter of the shaft: 70mm

6.Main power: 4KW

7.Forming steps: 16 steps

8.Material of shaft: 45#steel, quenched and tempered

9.Side board thickness: S18mm

10.Material of Rollers: Bearing steel

11.Driven style: by chain

12.Control system: Panasonic PLC

13.Hydraulic cutting part

i.Power: 3 KW

Material of cutter: Cr12, quenched

- Q: What are the shortcomings of traditional machining?

- Low efficiency, high cost, batch processing, then the processing quality is not stable, the accuracy is not high, labor intensity, processing staff, frequent processing times, and now good equipment to complete the car, drilling, milling and other processes.

- Q: Information on building materials decoration.

- Products Special Building Materials Ceiling Coatings Culture Stone Bamboo Processing Machinery Brick, Watt and Block Decorative Building Materials Agent

- Q: Information on building materials decoration.

- products special building materials ceiling paint culture stone processing machinery brick, tile and block decoration building materials agent operating reference:

- Q: Classification and components of hydraulic press

- According to the control mode classification According to the control mode, the hydraulic equipment can be divided into electronic control, machine control and manual control three categories.

- Q: Mechanical processing technology to mechanical product design, specifically to prepare what?

- Electrical aspects of more understanding to understand, engage in design to consider more problems, and often a project is not a person can get, need is a technical team.

- Q: Main classification of hydraulic machinery?

- (3) according to the degree of precision equipment according to the degree of precision, hydraulic equipment can be divided into precision equipment and general equipment.

- Q: What gear is machined out of the gear?

- Early in the universal milling machine, with the indexing head index, with the shape of the cutting edge and gear groove shape of the same forming disc cutter or milling cutter milling manufacturing.

- Q: What is the principle of the cutting order in machining?

- That is, the first should be used as a refined reference surface, and then processed to the basis of precision positioning for the processing of other surfaces.

- Q: What are the aspects of the mechanical processing quality

- Parts of the processing accuracy includes three aspects of the content; dimensional accuracy, shape accuracy and position accuracy

- Q: What are the oyster processing companies?

- other electronic processing metal processing including | casting pressure processing welding and bonding heat treatment cutting sheet metal processing Electroplating processing CNC and CNC machining line cutting processing other metal processing glass processing ceramic processing rubber processing including rubber rolling processing rubber molding processing rubber post processing processing other rubber processing plastic processing including injection molding extrusion processing blow molding processing plastic processing plastic processing casting Plastic Processing Plastic Surface Treatment Other Plastic Processing Textile Processing Including Spinning Processing Weaving Processing Dyeing & Finishing Quilting Processing Embroidery Processing Hand Knitting Processing Other Textile Processing leather processing entertainment leisure products processing health care products processing business printing processing including brochures

Send your message to us

highway deck forming machine in different trypes

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 8 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords