High Tenacity Polyester Fiber for Concrete

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

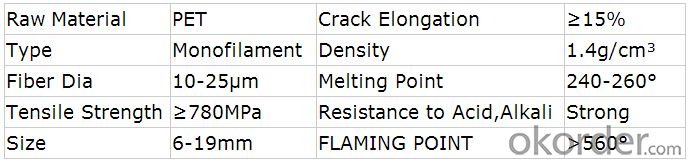

1,Specificationof High Tenacity Polyester Fiber for Concrete

2,Introduction of High Tenacity Polyester Fiber for Concrete

Polyester fiber is also called engineering fiber, concrete fiber, anti-cracking fiber,synthetic fiber or plastic fiber.

We use high tenacity polyester resin as the raw material , the fiber is produced through adding some functional additive, by plastic melting, extruding, high-ratio stretching and special surface disposal. And shaped by cutting with special machine Its appearance is beam-like structure with many monofilament fiber collecting. Besides the small thinness, high tensile strength and easily scattering, polyester has good heat-resistance. It can be used in hot-mixing bitumen concrete projects and reinforced crack-resistance for high-tensile concrete, so it is an ideal multi-functional

reinforced material.

3, Package of Polyester fiber

PP woven bag or carton.

4, Applicaiton of Polyester Fiber

Asphalt pavement of steel structure bridge deck.

Asphalt concrete pavement.

Newly-built asphalt concrete pavement.

Airport runway and paking apron.

5, Images of the Fiber

6.FAQ

We have organized several common questions for our clients,may help you sincerely:

1>How about your company?

A manufacturer & supplier focuses on the production of PP related product that used as the raw material of textile, automotive interior and constuction projects etc. Have been in this field for many years, with rich experience.

2> What's the MOQ?

1x20'GP or1x40'HQ will be better as the price would be economical based on full container load.

3>How long can we receive the product after purchase?

It takes about 1 to 2 weeks to finish the production based on the specific production schedual. Then it will depend on the shipping time from loading port to the destination port.

- Q: What are the uses of nanofiber filaments?

- Nano functional finishing technology, mainly refers to the nanometer raw material into forming a protective layer of fabric fiber, unique physical and chemical properties by nanotechnology, increase and improve fabric waterproof, anti oil, anti fouling, breathable, antibacterial, environmental protection, easy to change color, feel comfortable and other aspects of the features, and improve the textile fabric wearing performance, gives the fabric antibacterial health, UV shielding, anti oil and other new characteristics of easy care.

- Q: What do you mean by "T300 T700" in carbon fiber?

- Carbon fiber T number refers to the level of carbon materials, industry refers to Japan's Dongli company produced a certain kind of carbon material, the industry generally refers to the ultra-high precision carbon materials. How many T refers to the cross section area of 1 square centimeters of the number of units of carbon fiber can withstand tension tonnage. So in general, the higher the T number, represents the carbon level is high, the quality is better.

- Q: Polyester fiber is not environmentally friendly fabrics?

- Polyester fiber with high strength and elastic recovery ability, so the fastness and durability, anti crease. It's good lightfastness, other than acrylic difference, the light is more powerful than natural fiber fabric, especially in the glass behind the light ability is very good, almost be roughly the same with acrylic. In addition, polyester fabrics resistant to a variety of chemicals, good performance, acid and alkali damage to them are not large, while not afraid of mildew, but also not afraid of moth eaten.

- Q: What are the characteristics of bamboo fiber socks? What are they good for men?

- Bamboo fiber socks are made of natural bamboo as raw material, processed by special high technology, extracted cellulose from bamboo, and then regenerated cellulose fiber by making glue, spinning and other processes. Mayr Butler bamboo fiber socks using high-tech means of production, does not contain any chemical additives, has the good permeability, instant water absorptivity, wear resistance and good dyeing properties, but also has a natural antibacterial antibacterialdivide mite anti self and anti ultraviolet function. It is a kind of natural environmental friendly green fiber in the true sense.

- Q: Is summer shorts good for polyester or pure cotton?

- What is it about polyester chiffon, cotton do feel comfortable, I would choose the selection of polyester fiber, 100% cotton can not wear a few times to wash forms, unless the style let me move to the no, also see style sister paper

- Q: Polyester fiber, polyester, acrylic, spandex have any harm to the body?

- Generally speaking, polyester fiber (polyester fiber), acrylic fiber and spandex have no harm to the body.

- Q: What is the raw material of viscose fiber?

- Viscose fiber, a staple variety of man-made fibers. From natural cellulose alkalizing and alkali cellulose, and carbon disulfide formation of cellulose xanthate, dissolved in dilute lye in the viscous solution obtained by wet spinning of viscose rayon said, and a series of processing into viscose fiber.

- Q: Structural performance difference between polyacrylonitrile and carbon fiber

- The chain structures undergo cyclization and crosslinking during the pre oxidation stage to form a heat-resistant ladder structure. The carbon phase is conjugated to form the carbon base surface during the carbonization stage, and the carbon base surface grows up and finally forms a graphite like structure.

- Q: Why carbon fiber is an inorganic macromolecule compound?

- The distinction between organic and inorganic compounds is not in the absence of carbon, but in the division of structure and chemistry. For example, organic compounds, except for a few, are generally capable of burning. Compared with inorganic materials, organic compounds have less thermal stability and are easily decomposed by heat

- Q: Will the material be 100% polyester fabric?

- Cotton is more expensive than it is now, the people pay attention to the pure natural cotton, but expensive, this is the name of many manufacturers clothes containing cotton ingredients and raise the price of cotton and polyester fiber together can complement each other, good wear comfort, but relatively speaking cotton cost is reduced, but the pit% polyester fiber the 100 is not good, after all, this material is a chemical compound material, is not conducive to good health

Send your message to us

High Tenacity Polyester Fiber for Concrete

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches