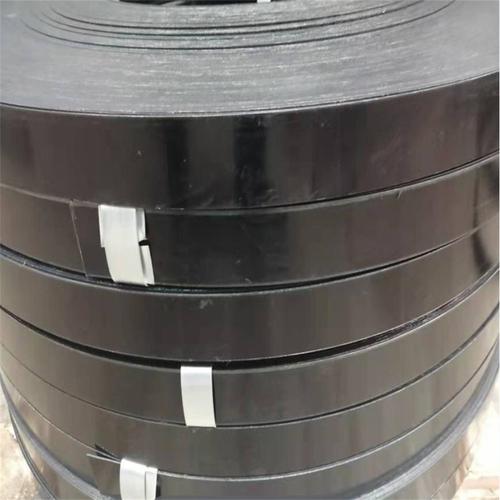

High strength straight disc painted packing tape

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 kg

- Supply Capability:

- 2500 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

High strength straight disc painted packing tape

Painted packing tape is an important material widely used in logistics, packaging, construction and other fields.

Painted strapping has the following advantages:

1. It has good tensile resistance and is not easy to break;

2. It has good corrosion resistance and wear resistance, and can be used for a long time;

3. It has good insulation performance and can protect packaging items from static electricity and electromagnetic interference;

4. It has good environmental performance and can be recycled and reused.

Process: Hot rolled coil - acid pickling - cold rolling - slitting - annealing - dipping - air drying - coiling - finished product packaging

According to strength, it can be divided into low strength (550-650Mpa), medium strength (650-750Mpa), high strength (750-850Mpa), and ultra-high strength (850-950Mpa)

Technical requirements: The surface is allowed to have individual concave surfaces, protrusions, longitudinal scratches, and abrasions greater than half of the allowable thickness tolerance, but there must be no rust, and the edges must not have burrs, edges, or uneven cutting.

Usage: Painted strapping tape is mainly suitable for packaging and bundling steel plates, steel coils, steel pipes, aluminum ingots, zinc ingots, light textiles, wooden products, and other steel strips.

- Q: What material is the packing belt made of?

- PET plastic is the abbreviation of Polyethylene terephthalate in English, referred to as PET or PETP. Polybutylene terephthalate mainly consists of polyethylene terephthalate, two ester PET and polybutylene terephthalate two PBT. Polyethylene terephthalate is also commonly called polyester resin. It is a condensation of terephthalic acid with ethylene glycol and is collectively referred to as thermoplastic polyester, or saturated polyester, with PBT.

- Q: What are the classification of the packing belt?

- In nature, PP and PET are classified;The material is divided into regeneration material and new material;The belt and the manual packing belt are used for the extension.

- Q: What should I pay attention to, such as whether it should be printed on the inner surface or the outer surface? Also, can the pure transparent packing belt be printed? What are the special requirements for ink? Will increase the cost, etc., we sincerely hope that your heroes.

- First of all, the extruder temperature control is generally between 250 and 280 degrees centigrade. The next is cooling, strip out the head temperature is very high, to immediately enter the water cooling, because of isotactic polypropylene in acute cold conditions easily generated has crystal structure, molecular structure of paracrystals was loose. In this way, the strap is easy to stretch and obtain high quality products. Then, the tensile and tensile purposes are to increase the longitudinal strength of the strap and reduce the elongation. Tension must be carried out in boiling water, usually by one stretch. Finally, the embossing, stretching after the packaging belt, after two patterns of pressure roller, it will be pressed on the pattern, its role is to increase friction in use, do not slip, from the appearance of looking handsome.

- Q: Where can I get a tin strap?

- Because of the influence of heating, cooling and other temperature in the electroplating process, the zinc plated baling strip has the same stamping performance as the cold rolled primary plate. The zinc plating layer does not produce a fragile iron zinc alloy layer, and the galvanized layer has good extension performance, but because of the pore surface, low strength and easy scratch, it is easy to be polluted by dry paint and the like.

- Q: What kind of joints are used in the packing belt?

- Ligature type packing.Ligation packing such a joint way is the soft plastic rope, rope, tied materials, packing belt in joint into a. The joint method is firm, beautiful and easy to untie. The straps are made of PP and PET, two plastic mixes. Main production: plastic particle melting - pressure - cooling - winding - molding - Packaging - packing belt storage system using polypropylene mesh structure through the packaging material heating, melting, stretching and cooling to produce the effect of packing quality is the basic parameters of belt tension, length, bending and elongation etc.. Under the same tension and other parameters, the longer the length, the lower the cost.

- Q: How much is a tin strap?

- Do not press the volume, sold by ton

- Q: What adhesive tape do you use?

- The weight of a small carton, can use plastic packing belt packing, common polyethylene and polypropylene resin as the main raw material, but also to nylon and polyester, polyester and the tensile strength of nylon strap, and polyethylene and polypropylene strapping polypropylene with low cost, good elasticity, can be selected according to different material the strap needs.

- Q: What's the function of the carton packing belt?

- Carton packing belt is mainly used for bundling cartons, strapping goods and convenient transportation, PE automatic end zone since 1989 from Japan and Taiwan to introduce automatic strapping machine after use, is characterized in that the demand is high, if not the use of new raw material for the production of the end zone will make the knotter strapping machine is worn, but also cause the operation is not smooth, tardy, error. With the recent years in the end of PE automatic carton packaging, printing and packaging, washing industry, towel factory, more and more vermicelli factory, manufacturers gradually increased

- Q: What types of Baling straps are used for packing?

- Wooden boxes, color coated sheet, strip, steel plate, steel wire, welded pipe, aluminum ingot, magnesium ingot, zinc ingot baling etc. different zinc plating method of packing tape: hot galvanized steel packing belt because it is in the hot galvanizing production line, through continuous annealing, continuous hot dip galvanizing liquid steel is heated in a short time and the cooling performance than the original cold rolled sheet stamping. Electric galvanized belt in electroplating process, is not affected by the heating and cooling temperature, so the stamping is roughly the same. The original properties of cold rolled plate of the galvanized layer, without formation of fragile Fe Zn alloy layer, good ductility of galvanized layer but, because of its surface porosity, low intensity, easy to scratch, prone to dry paint pollution.

- Q: Can the plastic steel line replace the cotton packing belt? It is used for cotton packing and cotton packing

- Plastic steel wire can be made of type 200 cotton bales. Type 400 bales can be packed in strips instead of steel wires.

Send your message to us

High strength straight disc painted packing tape

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 kg

- Supply Capability:

- 2500 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches