High Strength Pultruded Structural Profile of FRPPultrusion Machinery

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 set

- Supply Capability:

- 50 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

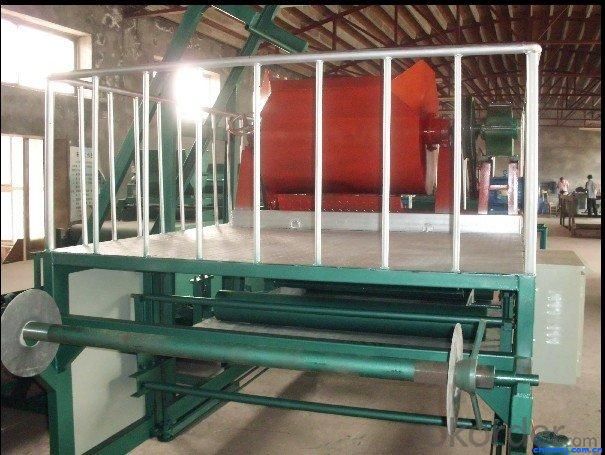

High Strength Pultruded Structural Profile of FRPPultrusion Machinery

Product Description:

This series plastic machine adopted four-column type construction, has the independent electrical and hydraulic power mechanism, hydraulic control part adopts advanced cartridge valve integrated system, long service life,simple structure, compact, reliable, convenient maintenance, high degree of generalization; Electrical control system with special pressure maintaining timing, automatic filling pressure, product count and temperature control device

Product Advantages:

1) Convenient and reliable installation, low construction expenses.

2) Excellent heat-insulation property from minimum thermal conductivity.

3) Light weight, convenient to transport and handle, good for labor-saving.

4) Smooth inner walls reduce pressure loss and increase flow speed.

5) Excellent design ensure suitability for both exposed and hidden installation.

6) Recyclable, environment-friendly, accords with GBM standard.

Product Parameter:

Product name | High Strength Pultruded Structural Profile of FRPPultrusion Machinery |

Material composition | Fiberglas Reinforced Plastic |

Resin type | FRP Grating Machine |

Color | Black , white , red , green , yellow , blue , grey or customized color |

Surface material | Smooth,GritFine grit,Concave,Grit cover,Chequer cover |

Dimension(L*W*H) | 19x19x38x38mm |

Certificate | ISO9001 |

Feature | Aging-Resistant,insulation,corrosion resistance |

Keywords | FRP grating |

Size | Customised Size |

product keywords | frp molded grating machine |

Product Pictures:

- Q: What kind of equipment do household workshops need to process plastic products? Can you make money? What are the sales channels?

- The biggest investment is the injection molding machine, as well as three-phase power, it is best to understand the machinery will repair the mold, there is a stable processing order, you do not need to sell it!

- Q: Rubber, plastic, machining specialty, which university is good?

- Dalian Light Industry Institute, Tianjin College of Light Industry, Chengdu University of Science and Technology are good.

- Q: The manufacturing process of plastic products? Who knows?

- 1. the manufacturing process of plastic products, that is, the processing of plastic bottles, refers to the process of making the final plastic products from polymers made from synthetic resin manufacturing plants. 2., processing methods (and plastic processing), including: plastic (Molding), extrusion (extrusion), injection molding (injection molding), blow molding (hollow forming), rolling and so on. Detailed manufacturing process flow:(1) press molding: molding or pressing forming. Plastic molding is mainly used for molding phenolic resins, urea formaldehyde resins, unsaturated polyester resins and other thermosetting plastics.(2): extrusion, extrusion molding, extrusion machine is used (extruder) will be heated by continuous resin mold, extrusion method of desired shape. The extrusion molding sometimes have to thermosetting plastic, and can be used for foam molding. The advantage of extrusion is that it can extrude various shapes of products. The production efficiency is high, it can be automated and continuous production. The disadvantage is that thermosetting plastics can not be widely used in this process, and the size of products is prone to deviation. (3) injection molding: injection molding. Injection molding is an injection molding machine (or injection machine) that uses thermoplastic melts to be injected into the mold at high pressure to cool and solidify the product. Injection molding can also be used for the formation of thermosetting plastics and foams. Injection molding has the advantages of high production speed, high efficiency, automation in operation, and the ability to form complex parts. It is especially suitable for mass production. The disadvantage is the high cost of equipment and moulds, and the difficulty of cleaning of injection molding machines.

- Q: from raw material to particle forming, need several devices, what are they? _?

- I also want to open such a factory, does the profit? I'm using scrap plastic as a particle here, so I want to check it out.

- Q: Laizhou plastic processing plastic machinery and equipment, which is more reliable, relatively good?

- In contrast to many manufacturers of plastic processing equipment, more important is environmental protection, there is calm in the future, if you want to buy the equipment you can go to Laizhou city to take a look at the field, there are a lot of home doing well, you have this problem too vague, but also do not know you to play some bottom in figure what product, change a problem to try again

- Q: How are the plastic products made of this texture processed?

- FormingKey links in plastic processing. The various forms of plastic (powder, granular, solution or dispersion) made products or blank of desired shape. As many as 30 kinds of molding method. Its choice is mainly determined by the type of plastic (thermoplastic or thermosetting), the starting form, and the shape and size of the product. The commonly used methods for processing thermoplastics are extrusion, injection molding, calendering, blow molding and thermoforming. Thermosetting plastics are generally molded, delivered and molded by injection molding. Lamination, molding and thermoforming are the processes of forming plastics on a flat surface. The plastic processing method can be used for rubber processing. In addition, there are liquid monomers or polymers as raw materials such as casting. In these methods, extrusion and injection molding are the most widely used and the most basic molding methods.MachiningThe use of metal and wood processing methods, such as the manufacture of very accurate or small amount of plastic products, can also be used as molding auxiliary processes, such as extrusion section sawing. Because the thermal conductivity of plastic and metal and wood properties of different plastics, thermal expansion coefficient, low elastic modulus, when the fixture or tool pressure is too large, easy to cause deformation, cutting heat melting, and easy adhesion on the cutter. Therefore, the plastic processing, the tools used and the corresponding cutting speed, etc., should be adapted to plastic characteristics.The commonly used mechanical processing methods are sawing, cutting, punching, driving, planing, drilling, grinding, polishing, thread processing and so on. In addition, the plastic can also be used laser cutting, punching and welding.

- Q: Which kind is with a lid, hollow, a little like PP material, white is a little transparent. It used to be filled with oil or wine. How is it processed? What company has custom-made?. Need to make the tank.

- Blow molding die processing, general plastic products manufacturers should have the ability to produce.

- Q: Benefits of plastic products

- The most lightweight plastic, chemical stability, will not rust; the good impact resistance; the transparent and has good wear resistance; the good insulation, low thermal conductivity; the general molding, coloring is good, the processing cost is low; most heat-resistant plastic, thermal expansion. Easy burning; poor dimensional stability, easy deformation; majority of poor low temperature resistant plastic, low temperature brittle; easy to aging; some of the plastic soluble in solvents.

- Q: What kind of equipment does the groove on the PP plastic board work on?

- It can be machined with a shaper or engraving machine

- Q: How do we calculate the cost?

- So many people bought equipment and started, most of the friends have just started, mainly chemical fiber bags (PP woven bags) granulation, plastic film granulation, plastic bottles, broken materials, and so on.2, followed by the main problem is the use of equipment:1). Performance of the equipment are not familiar with the problems of using too much, such as temperature control is not good (low price devices do not have automatic temperature control system, through experience), products can not achieve the desired requirements, the color is not good, drawing off a serious, low yield, often blocking filter, cutting unevenness, severe adhesion.2) raw materials sorting is not clear, cleaning is not in place, impurities, broken bar serious, bad color. The same raw materials, the same approach, the product is not as good as others, the price is far from.3), procurement of raw materials, usually all recycled plastic, when you formed a batch production, to ensure the supply of raw materials can not be too much, impurities in raw materials procurement, and even pit you encounter people, buy a home is water, stone bag.4) sales problems: I don't know who sells the products. I don't know what the price is, or even say you have such and such problems.Moreover, the beginning of production, it is impossible to form mass production, small amount of bad sales, because customers need to be generally enough to a car to load, 2T-3T is not good, and more afraid of production, fear of backlog.

Send your message to us

High Strength Pultruded Structural Profile of FRPPultrusion Machinery

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 set

- Supply Capability:

- 50 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords