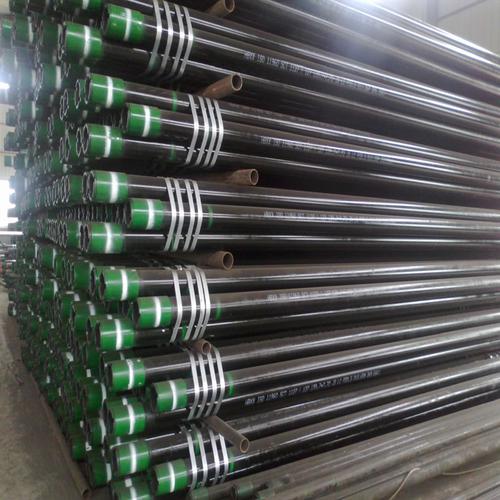

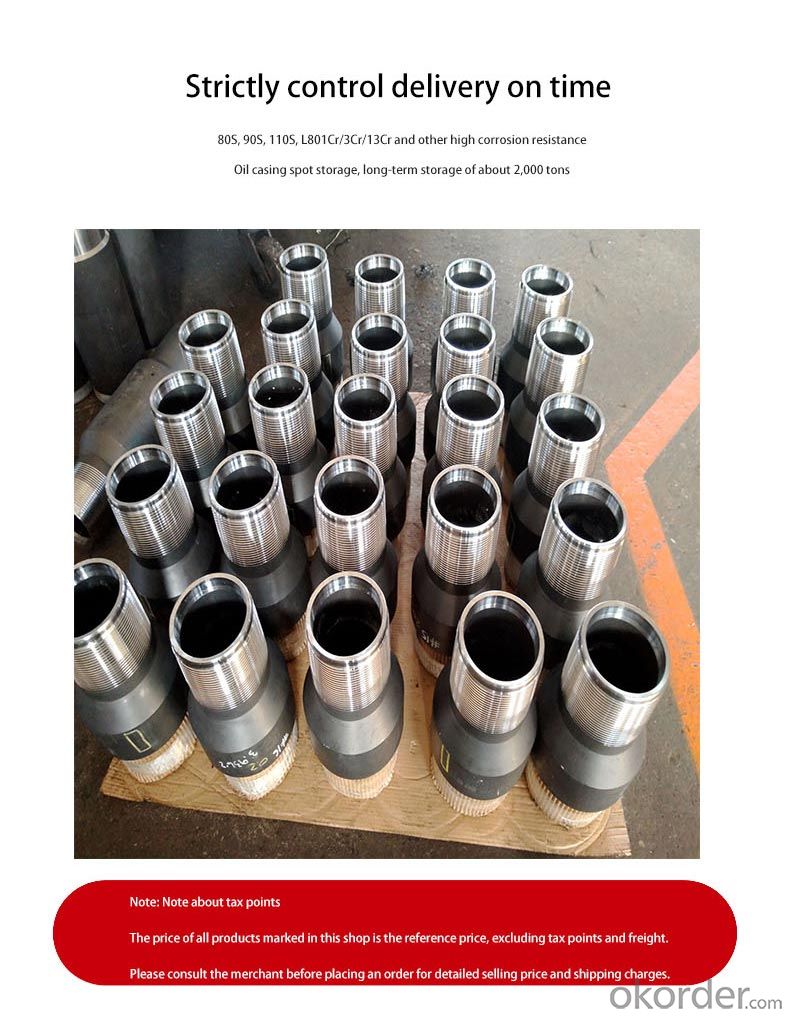

High-Strength P110 Casing Couplings with Premium Threads Bulk Stock

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1400 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

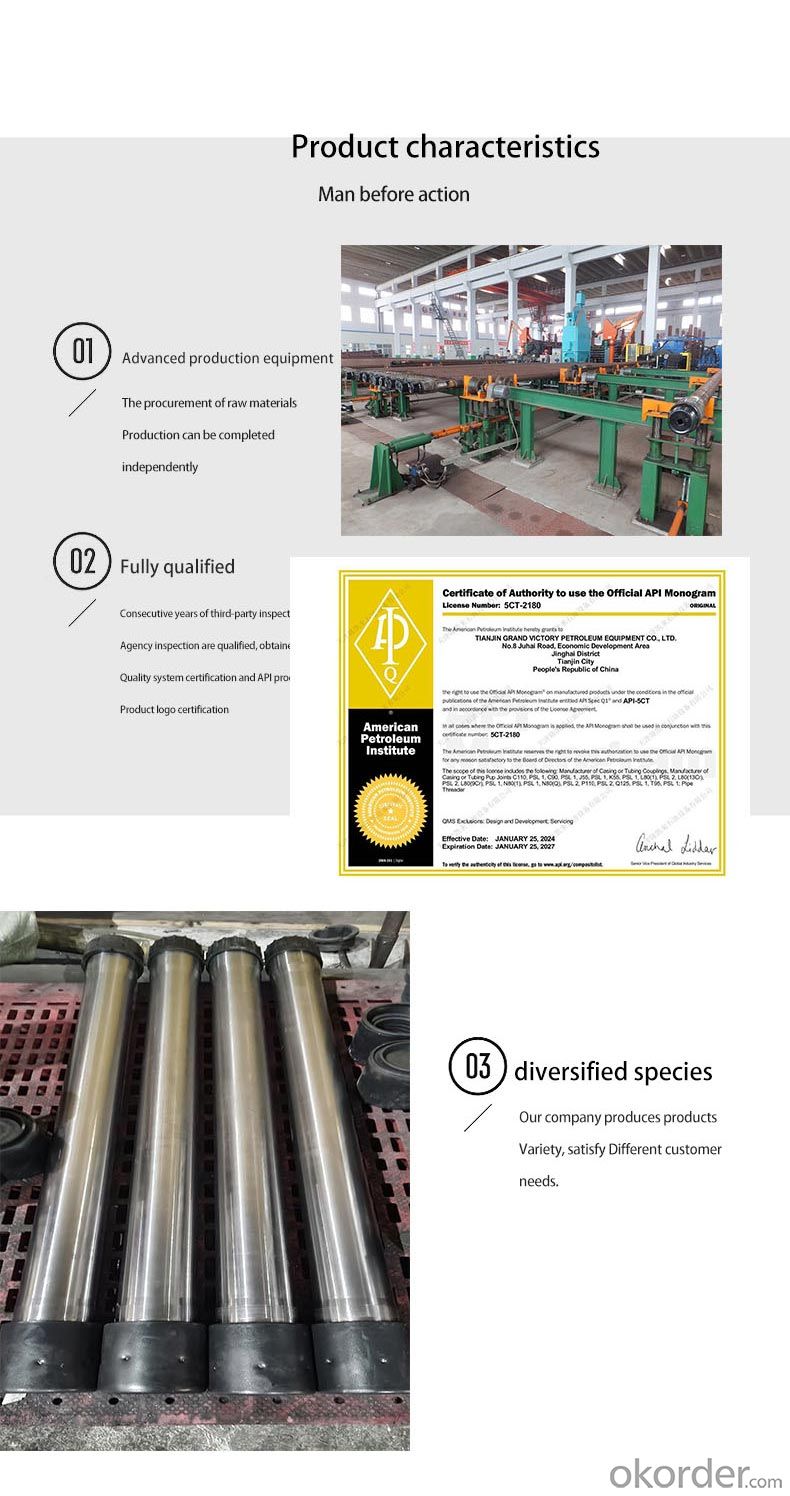

API 5CT J55/N80/P110 OCTG Casing & Tubing Manufacturer Direct

Comprehensive OCTG Solutions for Every Well Profile

As an API-licensed manufacturer, we eliminate intermediaries to deliver J55/N80/P110 casing and tubing with 15% cost savings. Our vertically integrated production process ensures full traceability from steel billet to finished product.

Technical Specifications

Material Science:

J55: 0.45% Mn, 0.25% C composition for shallow wells (≤8,000ft TVD)

N80: Quenched & tempered microstructure withstands 12,000psi collapse pressure

P110: 110ksi SMYS with Charpy V-notch impact ≥45J at -20°C

Threading Technology:

CNC-machined API LTC/BTC threads with ±0.003" pitch diameter tolerance

Optional VAM TOP connections for HPHT wells

Quality Assurance:

100% ultrasonic testing (UT) for laminations

Hydrostatic tested to 80% of yield strength

Applications

J55: Water injection wells, surface casing

N80: Intermediate casing in sour gas fields

P110: Production casing in 15,000psi reservoirs

Case Study

A Permian Basin operator reduced casing costs by 18% using our direct-shipment P110 casing for 35 horizontal wells, achieving 95% torque-turn compliance during running

- Q: What is the role of steel pipes in the telecommunications industry?

- Steel pipes play a crucial role in the telecommunications industry as they are used for the installation of underground and overhead telecommunication cables. These pipes provide protection and support to the cables, ensuring their safety and longevity. Additionally, steel pipes are also used in the construction of communication towers and infrastructure, making them an essential component in establishing and maintaining reliable telecommunications networks.

- Q: How are steel pipes tested for quality?

- Steel pipes are tested for quality through various methods such as visual inspection, dimensional measurement, mechanical testing, and non-destructive testing. Visual inspection ensures that there are no surface defects or deformities on the pipes. Dimensional measurement involves checking the pipe's size, thickness, and length to meet the required specifications. Mechanical testing involves subjecting the pipes to stress, pressure, and temperature to assess their strength and durability. Non-destructive testing techniques like ultrasonic, radiographic, or magnetic particle testing are used to detect any internal flaws or defects without damaging the pipes. These comprehensive quality tests ensure that steel pipes meet the necessary standards before they are used in various applications.

- Q: How are steel pipes used in the construction of pipelines?

- Steel pipes are commonly used in the construction of pipelines due to their strength, durability, and resistance to corrosion. They are typically laid down and welded together to form a continuous pipeline that can transport various fluids, such as oil, gas, or water, over long distances. The steel pipes provide a reliable and efficient means of distribution, ensuring the safe and efficient transfer of resources in the construction industry.

- Q: What is the fatigue strength of steel pipes?

- The ability of steel pipes to withstand repeated cyclic loading without failing is referred to as their fatigue strength. This characteristic is of utmost importance for pipes that experience dynamic or fluctuating loads, such as those used in the oil and gas industry, transportation infrastructure, or industrial applications. Several factors can affect the fatigue strength of steel pipes, including the grade of steel, dimensions of the pipe, manufacturing process, surface conditions, and environmental factors. Generally, steel pipes with higher tensile strength and toughness exhibit better resistance to fatigue. Fatigue strength is typically determined by subjecting the pipes to cyclic loading until failure occurs, through a process known as fatigue testing. The results of these tests are then used to establish a fatigue curve or S-N curve, which illustrates the relationship between the applied stress amplitude and the number of cycles required for failure. To quantify the fatigue strength, it is common to express it as the stress amplitude required to cause failure after a specific number of cycles, such as the stress amplitude at 10 million cycles (S-N10^7). However, it is important to consider other factors such as mean stress, surface finish, and loading frequency, which can also influence fatigue strength and may require consideration in specific applications. Ultimately, the fatigue strength of steel pipes is a crucial factor in engineering design and maintenance, as it ensures the long-term integrity and reliability of the pipes under cyclic loading conditions.

- Q: How are steel pipes used in the telecommunications infrastructure?

- Steel pipes are used in the telecommunications infrastructure primarily for underground cable installation. They serve as protective conduits that house and secure the fiber optic cables, providing a reliable and durable solution for long-distance communication.

- Q: Can steel pipes be recycled and used for other purposes?

- Yes, steel pipes can be recycled and used for other purposes. Due to their durability and strength, steel pipes can be melted down and repurposed for various applications, including construction, manufacturing, and infrastructure projects. Recycling steel pipes not only saves resources but also contributes to reducing waste and promoting sustainability.

- Q: Can steel pipes be used for underground gas pipelines?

- Yes, steel pipes can be used for underground gas pipelines. Steel pipes are often the preferred choice for underground gas pipelines due to their strength, durability, and resistance to corrosion. They can effectively handle the high pressure and extreme temperature variations associated with transporting gas underground.

- Q: How are steel pipes used in railway infrastructure?

- Steel pipes are used in railway infrastructure for a variety of purposes. They are primarily used for constructing and maintaining railway tracks, as they serve as the support structure for the rails. Steel pipes are also used for the fabrication of various components such as bridges, signal systems, and overhead power lines. Additionally, steel pipes are utilized in the construction of tunnels, culverts, and drainage systems to ensure proper water management along the railway lines.

- Q: Are steel pipes suitable for underground mining applications?

- Steel pipes are a great choice for underground mining. The mining industry has been using steel pipes for a long time, and they have many different uses, such as supplying water, providing ventilation, and moving materials. Steel pipes are strong and durable, making them perfect for the tough conditions of underground mining. One of the reasons steel pipes are so good for underground mining is their high tensile strength. This means they can handle the pressure and stress from the rock and earth around them. They can also carry heavy loads, which is important for transporting materials and supporting structures in mining tunnels. Another advantage of steel pipes is their resistance to corrosion. This is really important in underground mining, where there's often moisture and chemicals around. With steel pipes, you don't have to worry about them getting damaged and needing to be replaced or repaired all the time. Steel pipes are also easy to weld and join together. This means they can be customized to fit different shapes and sizes to suit the specific needs of each mining operation. To sum up, steel pipes are a fantastic choice for underground mining because they're strong, durable, resistant to corrosion, and versatile. They've been proven to be effective in supporting mining operations and ensuring safety and efficiency.

- Q: Can steel pipes be used for paper mills?

- Yes, steel pipes can be used for paper mills. Steel pipes are often used in paper mills for various applications such as transporting water, steam, chemicals, and pulp. They are preferred for their durability, resistance to corrosion, and ability to handle high pressure and temperature conditions commonly found in paper mill operations.

Send your message to us

High-Strength P110 Casing Couplings with Premium Threads Bulk Stock

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1400 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Related keywords