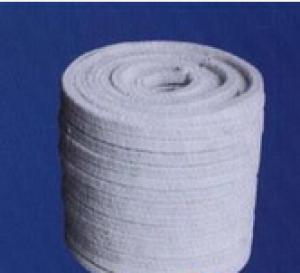

High Strength Chopped Strand Glass Fiber Ceramic Fiber Textiles

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 600 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

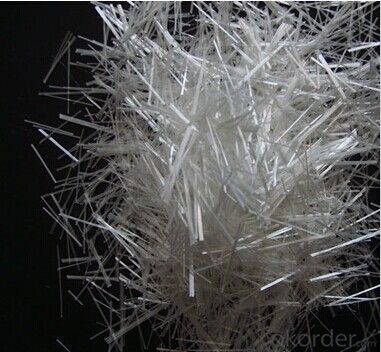

high strength chopped strand glass fiber

1. factory since 2005

2. ISO management

3. quickly delivery

4. customer requirement

A. length:3.0mm,4.5mm,6.0mm,9.0mm,12mm,15mm

B. Good strand integrity

C. low static

D. good flowabilit

Good choppability and good gathering

Good strand integrity and low fuzz

Low static, excellent mechanical properties.

Excellent pigmental and color matching property

Application:

Mainly used in injection and compression molding processes and its typical end-use applications include automotive industry, home appliances, valves, pump housings, chemical corrosion resistance and sports apparatus.

Product Code | CYS-E327 |

Filament Diameter(μm) | 13 |

Chopped length(mm) | 3,6,9,12,24,48 |

Compatible Resin | UP, VE, Phenolic |

Application | Car components, break systems, Sanitary wares and so on. |

Linear Density(%) | Filament diameter | Moisture content(%) | LOI(%)

|

±5 | 13μm ±1 | ≤0.1 | 1.20±0.15 |

Fiberglass roving should be stored in its original packing in a dry and cool place. Best conditions are at temperatures from 15 to 35°C and humidity between 35 to 65%. To ensure safety and avoid damage to the product, the pallets should not be stacked more than three layers high, when the pallets are stacked in 2 or 3 layer, care should be taken to correctly and smoothly move the top pallet.

- Q: Is aluminum silicate fiber completely insulated from heat transfer?

- Fire-resistant insulation layer is used to make ceramic fiber module insulation, thermal insulation thickness of four hundred mm, the ceramic fiber blanket double extrusion, ceramic fiber module in parallel sorting, the trolley furnace wall temperature to plate temperature rise of forty-five degrees, which is almost a best isolation effect.

- Q: What is the function of (ceramic) ceramic powder?

- In the process of porcelain fused to metal (PFM), the powder material used for sintering and making ceramic restoration is made. There are long stone and alumina ceramic powder, as well as a variety of crystal reinforced porcelain powder, high temperature porcelain powder and low temperature porcelain powder.

- Q: Is everybody's ceramic fiber cloth poisonous?

- Aluminum silicate fiber textiles can replace asbestos textiles, widely used in metallurgy, chemical industry, ceramics. Glass, refractories, shipbuilding, aerospace, automotive, machinery, electronics, building materials, light industry and other industrial sectors of the fire-resistant, heat insulation, fire prevention, friction, sealing, silencing, labor protection, high temperature filtering etc..

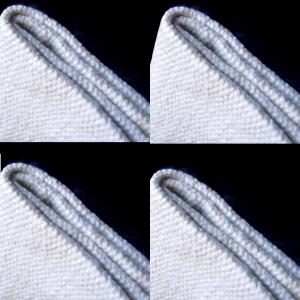

- Q: Can ceramic fibers be spun?

- The utility model can also achieve higher strength by increasing metal wire reinforcement, and finally can be made into products such as yarn, cloth, belt, rope, packing, etc., and the utility model has wide application.

- Q: What's the temperature of the high temperature ceramic fiber cloth and ceramic drill cloth?

- The ceramic fiber cloth is only one kind of one thousand degree temperature resistance. It is reinforced cloth for steel wire.

- Q: What are the differences between digital textile printing ink and printing ink?

- Under the new economic environment, the textile industry will enter a short process, digital production mode. Nowadays, more and more printing and dyeing mills use wide format inkjet printing to produce.

- Q: What are the man-made fibers polluting the environment?

- Fibers are roughly divided into natural fibers, man-made fibers, and synthetic fibers[natural fiber] refers to the natural growth or formation of fiber, including plant fiber (natural cellulose fiber), animal fibers (natural protein fiber) and mineral fiber. Plant fibers include: seed fiber, phloem fiber, leaf fiber, and fruit fiber. Seed fiber is the unicellular fiber that grows from the epidermal cells of some plant seeds. Such as cotton, kapok. Bast fiber is a single fiber or process fiber obtained from the phloem of some plants. Such as: linen, ramie, jute. Leaf fiber is the process fiber obtained from the leaves or sheaths of some plants. Such as: sisal, abaca. Fruit fiber is the fiber obtained from the fruit of some plants. Coconut fiber. An animal fiber (natural protein fiber) that includes hair, fiber, and gland fibers. Hair follicles: fibers of the hair follicles that have multicellular structures and are composed of keratin. Such as: wool, cashmere, camel hair, rabbit hair, Ma Haimao. Silk fibers: fibers formed from the glands of some insects, especially those produced by lepidopteran larvae, and fibers formed by secretions of some mollusks. Such as: silk.

- Q: The difference between ceramic fiber cloth and ceramic fiber paper

- Ceramic fiber paper and ceramic fiber cloth are refractory insulation materials, which can be used for insulation and heat preservation

- Q: Which is better, ceramic fiber or spray velvet?

- Ji'nan Huolong thermal ceramics limited liability company to help you analyze: thrown silk and spray cotton, which is better? Which process is more suitable for producing carpets? Fire dragon energy saving from the technical point of view is as follows:1, fiber diameter: rejection fiber more coarse, rejection filament fiber is generally 3.0-5.0 mu m, spinneret fiber is generally 2.0-3.0 mu m;2, the length of fiber yarn: rejection fiber longer, the rejection of silk fiber is generally 150-250mm, spinneret fiber is generally 100-200mm;3, the coefficient of thermal conductivity: spray cotton fiber is lower than that of the thrown silk;4, the tensile and flexural strength: thrown silk because fiber thicker than that of spraying cotton;

- Q: Does the component of textiles contain 70% acrylic? Does it hurt the body?

- Acrylic may sound strange, because it is a new word that has appeared on the mainland in the last two years. It was not until 2002 that the advertising industry, furniture industry and handicraft industry were gradually understood by a few. "Acrylic" is a transliteration of foreign words, English is ACRYLIC, it is a chemical material. The chemical name is called "PMMA", which belongs to propylene alcohol, commonly known as "specially treated organic glass". In the application industry, its raw materials usually appear in the form of particles, plates, pipes and so on.

Send your message to us

High Strength Chopped Strand Glass Fiber Ceramic Fiber Textiles

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 600 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords