High Refractoriness Magnesite Bricks with Chrome - Good Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details for High Refractoriness Chrome Magnesite Refractory Bricks

| Place of Origin: | China (Mainland) | Shape: | Brick | Material: | Alumina Block |

| SiO2 Content (%): | 10-20% | Al2O3 Content (%): | 35-90% | MgO Content (%): | 0.0 |

| CaO Content (%): | 0.0 | Refractoriness (Degree): | Common (1580°< Refractoriness< 1770°) | CrO Content (%): | 0.0 |

| SiC Content (%): | 0.0 | Model Number: | NTZ | Brand Name: | |

| Size: | All size | Application: | High temperature kiln | Sample: | Avaliable |

Packaging & Delivery

| Packaging Details: | Pallet |

| Delivery Detail: | Within 15 days |

Product description

| Raw material of chrome magnesite refractory bricks |

The brick was made from high grade bauxite, and our factory is located in raw material sourcing place, thus which with high quality and cheaper price. Al2O3 content and brick size can be made according to requirements.

| Application of chrome magnesite refractory bricks |

1,Different high temperature kiln, such as cement kiln

2,Used as insulating layer

| Advantages of chrome magnesite refractory bricks |

1,Cheaper price compared with other refractofy bricks

2,Most widely application

3,Size can be made according to requirements

| Specification of chrome magnesite refractory bricks |

Item | Index | ||||

LZ-80 | LZ-75 | LZ-65 | LZ-55 | LZ-48 | |

Al2O3/% ≥ | 80 | 75 | 65 | 55 | 48 |

Apparent porosity/%, ≤ | 22 | 23 | 23 | 22 | 22 |

Cold crushing strength/Mpa ≥ | 55 | 50 | 45 | 40 | 35 |

0.2Mpa load softening temperature/°C ≥ | 1530 | 1520 | 1500 | 1450 | 1420 |

Permanent linear change/% | 1500°CX2h | 0.1~-0.4 | |||

1450°Cx2h | 0.1~-0.4 | ||||

For Us:

1.Scale: Three subsidiaries and one branch company

2.Output: 180,000 ton refractory products

3.Output value: Reached 350million yuan

4.Number of staff: 650 people

5.Certification:IS09001:2000, ISO14001,BV and TUV certification, SGS Certificastion

6.History: Specialized in manufacturing refractory products about 27 years

7.Main products: Shaped products such as refractory brick, refractory nozzle, ceramic fiber, slide gate, etc; unshaped products including repair, construction and casting mixes and mortars.

8.Trading nation: More than 20 countries, such as Thailand, Indonesia, Pakistan, Saudi Arabia, South Africa,Turkey, Iran, Iraq and so on.

FAQ

Q1: Are you a manufacture or trader?

A: Factory+trade (mainly for manufacturing, also do some business of related products).

Q2: What's the MOQ of trial order?

A: No limit,We can offer the best suggestions and solutions according to your requirements.

Q3: After an order is confirmed,when to deliver?

A: According to your order quantity, normally, 15-25 days after deposit received.

Q4: Is your company accept customization?

A: We have our own factories and excellent technical team, and we accept OEM service.

Q5: What certificates do you have?

A: ISO9001, BV and Test Report, also we can do other necessary certification according to your requirements.

Q6: Can you offer samples?

A: Of course,samples are total free! Freight should be paid by buyers.

Please feel free to ask if any further questions....

- Q: Brick price?

- There are various series of unshaped refractory gunning, magnesia ramming material, mending material, coating material, dry lining material, composite refining agent, covering agent, tundish and tundish slag wall, ladle drainage sand and electric furnace taphole filler etc..

- Q: The index of magnesia brick

- Room temperature compressive strength≥(MPa)(15-25-)24.5-24.5-24.5-24.5-40-40-40

- Q: High purity magnesia brick masonry mortar for what?

- High purity aluminum is 99.99, the first is not pollution, the stove is high magnesia brick masonry, 95% and 97% purity magnesia brick is for a long time did not find a good bit of fireclay, do not know what to build, now used light burned US powder and heavy burned magnesium plus brine built, with 2 months a griddle doesn't stick on magnesium brick, a touch off, there is no good sintering

- Q: Manufacture of various refractory magnesia brick mainly comes from Magnesium Oxide, what kind of ore?

- The ore quality requirements of MgO = 41%, CaO = 6%, SiO2 = 5%. The resources of magnesite in China are rich. The types of deposits include sedimentary metamorphic deposits, sedimentary hydrothermal metasomatic deposits and weathering leaching deposits.

- Q: Refractory brick, high alumina brick, magnesia chrome brick, magnesia brick, clay brick, which type of high temperature refractory brick?

- High alumina brick clay brick up to 1700 degrees above 1500 degrees -1750 degrees of magnesia brick and magnesia chrome brick 1500-1650 degrees, I is the production of clay brick, brick my temperature at 1500-1700 degrees. Specific depends on what kiln, brick is only part of it

- Q: With different capacitance magnesia brick brick

- It has good thermal stability, corrosion resistance and spalling resistance. Widely used in converter, arc furnace and other industrial furnace lining refractory.

- Q: How to identify the fused magnesia brick and sintered magnesia brick

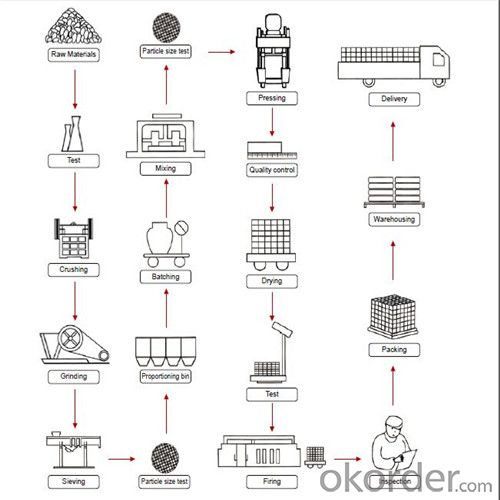

- Magnesia brick have high refractoriness, alkali slag good performance, high load softening temperature, but poor thermal shock resistance. The sintering magnesia brick brick magnesite as raw material, crushing, proportioning, mixing, forming, in 1550 ~ 1600 degrees firing, high purity products firing temperature is over 1750 DEG C. Don't add chemical bond magnesia brick is appropriate in magnesia, through mixing, molding and drying.

- Q: Process for producing magnesia chrome brick

- The fine powder compacts after calcination produced by magnesia - chrome ore grinding method, brick with magnesia coarse particles, are effective measures to eliminate the effect of loose. Compared with the common magnesia chrome brick, the magnesia chrome brick made by this method has lower porosity, higher compressive strength, higher softening temperature and higher flexural strength. Compacts with chrome magnesite powder, magnesia chrome brick by synthetic magnesia chrome sand made of high-temperature calcination, slag resistance and high temperature strength are better than other magnesite chrome brick.

- Q: How do you differentiate between the two clearly? Where is the key? Thank you

- Magnesia brick (magnesite brick) basic refractories Magnesium Oxide content of more than 90%, with the main crystalline phase of periclaseGeneral can be divided into sintered magnesia brick (also called burnt magnesia brick) and chemically bonded magnesia brick (also known as the two major categories of not burned magnesia brick). Purity and high firing temperature of magnesia, due to the direct contact of periclase grains, known as direct bonded magnesite brick; made of fused magnesia bricks called electrically fused magnesite brick.

- Q: Combined with the ordinary clay brick and magnesia brick as an example, the existence of impurities in minerals and refractories production main components of the formed liquid relative what affect the performance.

- The main varieties of common magnesia brick, magnesia brick, magnesia brick, magnesia brick high pure grade. Product main mineral phase is periclase, volume has high stability and anti erosion ability. Literature is widely used in steelmaking, non-ferrous metal smelting and other high-temperature industrial furnace.

Send your message to us

High Refractoriness Magnesite Bricks with Chrome - Good Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords