Supply magnesium oxide board,fireproof mgo board,magnesium board

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Magnesium Oxide Board

Magnesium Oxide Fireproof Board (usually called magnesium oxide board) is the building

material widely used in the construction area. The stable magnesium colloid is reinforced by

middle alkali glass fiber net and stuffed by light material then becomes new frameless

decorative material. 100% no Asbestos Contained and no radioactivity.

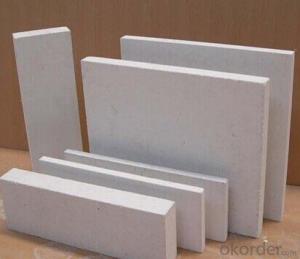

Main Characteristic

1. Fireproof, non-combustible Class A1

2. Waterproof, moisture-proof, anti-corrosion, acid and alkali resistance

3. Heat insulation, and sound insulation.

4. Low shrinkage rate, light weight, and high strength, overall low density.

5. Smooth surface, can be painted, pasted tile, pasted wallpaper and other decorative materials.

6. Excellent fire resistance performance.Using 12mm thickness plate can be made

partition, it can reach 4 hours of fire resistance.

7. Construction cost of low, and can be cut, saw,nail,and bent.

Composition:

MGO Board is also called magnesium oxide board, fireproof board, magnesium board, magnesia board, mag board and so on. It is popular and warmly welcomed by clients from all over the world.

Raw Material: Magnesium oxide(MGO), magnesium chloride, perlite, Wood dust, fiberglass mesh, non-woven cloth etc.

Usage: Partition wall, fireproof, heat resistant

We have many years experiance in building materials fields and related machines, we know many core supplier very well and we also have our own factory for some of the building materials and machines, we are professional and honest to our customer, please inquiry if you have any questions and give us a chance to show our professional;

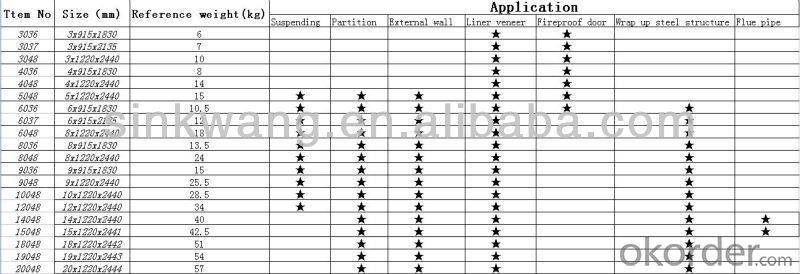

More details:

MGO fireproof sheet is a kind of environmental-friendly fireproof board widely used in construction and decoration. It's made from magnesium oxide, magnesium chloride, fiberglass mesh, sawdust, perlite etc. We use, highly-purified active MGO as the main fireproof material of board, high-quality MgCl2 as the main cementing material to solidify other materials, alkali-resistance fiberglass mesh to ensure the high strength of board, soft sawdust and light non-combustible perlite as filling materials.

MGO fireproof sheet enjoys strong points in more fields compared with the plasterboard and the traditional partition board, either in the decoration for modern construction or the fire resistent division for the industrial workshops

Features of the products :

1. Strong fireproofing capability: All the specifications of this product has reached the requirement of GB8624 fireproof level A and JC688-2006.

2. Good shockproof capability: This product is designed with many layers of high-strength fiber webs, which can effectively absorb part of the energy from the earthquake to avoid the instantaneous collapse of the isolation wall.

3. Smooth and scratchproof face: Advanced European and American production technology and recipes is introduced for this product, thus the turned-out board material is of smooth face and high hardness, collision and impacting will not result in depressions and scratches.

4. Good safety performance: This product is 100% free of asbestos and radiation, nor will it create the organic substance harmful to human bodies.

5. Superior performance in sound insulation and heat insulation: When used as the partition, this product can be filled inside to absorb sound, whose performance in sound insulation is better than the single brick wall meanwhile the cold and green house effect is raised, which saves energy and increases the economic benefit.

6. Damp-proof and non-reaction with halogen: The advanced and special production technology and recipes is introduced to cause the board material not to expand, peel off layer after layer, go moldy or react with the halogen like the plasterboard, silicic acid board or the common glassboard because of the damp environment, thus it can be widely used in the damper places such as bath-rooms, toilets and so on.

7. Wide applicable scope: Can be painted, jointed with wall-paper and sculpted or colored as the second processing.

8. Bend-proof: The structure of the board material is processed specially, thus the board material is flexible and elastic.

Applications:

- Q: Daya solid wood particle board is good? Wardrobe and cabinet with what plate to do better?

- Daya, one of the two largest domestic man-made sheet manufacturers. Environmental protection level and the second grip nail force are more. To distinguish this plate, it is best to have the official authorization of Daya. Wardrobe: particle board is the most cost-effective preferred material, the domestic first-line brand only particle board material. If your place is very vulnerable to moisture. Can choose multi-layer solid wood board! (First-line brand foundry have to do). Not recommended woodworking board (Malacca), plate advantages: grip nail force wood is very good, shortcomings: the seam is not dense, once the joints in the joints, the wardrobe of the service life is seriously reduced. Something to buy lottery. Cabinet: the same solid wood particle board, the cabinet factory has a very good moisture treatment. Not recommended to spend money wasted, if not bad money can also choose other high-quality materials. Door: kitchen with more, try not to choose blister modeling series. Solid wood and carbon light board, and the general crystal steel doors can be! UV board acrylic best not!

- Q: Will the experts: acetic acid plate and the difference between acrylic, resin sheet

- Organic chemical chemical industry is so complicated, only conventional products conventional method, that is, specify the specific conditions. And that are colorless and transparent products it, designated conventional cellulose acetate plate, conventional acrylic plate, conventional thermosetting resin board. Among the three, you can see the degree of colorless translucent to the highest acrylic, followed by resin, acetic acid again. You can see heat conditions, heating to one hundred and fifty degrees above, acrylic will soften the flow, the resin will be soft but not flow, and then raise the temperature, acetic acid will melt. Look at the situation of specific solvents, dip chloroform (chloroform) wipe the surface, acrylic solution, slightly soluble acetic acid, resin unchanged. Of course, for the specific different varieties, the situation is very different

- Q: What is the actual thickness of all the thickness of the acrylic sheet?

- Acrylic panels are usually made of 1 mm, 2 mm, 3 mm, 4 mm, 5 mm, 8 mm, 10 mm, 12 mm, 15 mm, 20 mm, 25 mm, 30 mm and above thickness; Such as the need to buy thick acrylic sheet, but also can buy, but the market is rare; In general, some brands of acrylic thickness error of ± 0.2 mm; medium mass error of ± 0.45 mm; relatively poor recovery of material error is great, but the price is cheap. OKorder, China and respect for science and technology.

- Q: How to identify the millennium boat plate

- It is not what you do, belong to the cultural relics, and need archaeologists identification.

- Q: 1, if the nose is a metal support, you can hand to the middle of breaking off.

- 1, if the nose is a metal support, you can hand to the middle of breaking off. 2, if the whole into a whole is plastic, nasal care will not be deformed. It must be attached to the lens and the lens between the screws too loose, two mirror feet breaking too open, you can tighten the screw tight. 3. If you have a small wedge, you can tighten the screws on both sides of the frame, it is recommended not to break the glasses to the inside, because the improper grasp of the words easily broken In addition to the optical shop can have a special person will help you tune, of course, is generally selling glasses.

- Q: What is the overall cabinet?

- Of course, with solid wood board, but the price is very high

- Q: What is the problem with the plate at the time of picking?

- Plate quality, environmental protection, in particular the release of formaldehyde. Generally some brands of plates like Han master, bunny, millennium boat and so on. Product quality is very good, formaldehyde emission also reached the E0 standard.

- Q: Q235 material, 2.5mm thickness of the plate, flanging R corner of the smallest can not be less than how much? Is a material thickness? This problem is applied to similar flanging situation? Do sheet metal peers please help

- These are low carbon steel, brass, the bending factor, carbon steel bending coefficient than these data larger; are: 1.2,1.8,3.0.

- Q: How to degrease the wood

- High temperature drying method High temperature drying is considered to be a more effective degreasing method. Cech [2] has done a degreasing test of Korean pine wood, using a high-temperature drying method to reduce the average rosin by 274% and turpentine by 40 1%. If high temperature drying The rosin can reduce the rosin by 30% and the turpentine can be reduced by 65%. This method is mainly to remove the turpentine of the resinous acid that dissolves the solid because the boiling point of the turpentine is about 1 50 to 2 3 0 ° C, If the coexistence with water can be reduced to below 100 ℃. [3]. Turpentine volatile at high temperatures, and under high temperature steaming conditions to reduce the boiling point of turpentine, while high temperature steam to improve the permeability of wood, can be effective To evaporate the turpentine component, the remaining solid rosin after treatment will not exudate. High temperature plus steam combined dry is the most effective practical method, it does not need to add any equipment only the original drying kiln, so less investment , But many people use it, but some people think that after the role of high temperature and humidity, dry wood after the pine wood surface dark gray, dim, lost the original natural wood color, processed into products after the tan.

- Q: What are the environmental ratings of the board?

- E0 E1 E2 GB The domestic market is more common E0 and E1 can be used directly for home decoration E0 more expensive than the general choice of E1 more

Send your message to us

Supply magnesium oxide board,fireproof mgo board,magnesium board

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords