High quality 12.5mm quick-release ratchet

- Loading Port:

- Ningbo

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

High quality 12.5mm quick-release ratchet

1. Model No:971210

2. Handle:rubber handle

3. Size:10"(250mm)

4.Color:green & black handle

Samples:

1. Customer have to bear samples charge and courier cost.

2. Samples time: please check with service person if you need samples.

Advantage and Innovation:

1.Comfortable molded handles with soft, non-slip grips

2. Heavy duty

3.Lock-on, push-button, quick-release drive tangs prevent dropped sockets

Package and size:

| Model No. | Spec. | Pcs/Ctn. | G.W.(kg) | PACK.DIEM(mm) |

| 971210 | 10"(250mm) | 24 | 16.5 | 285*195*286 |

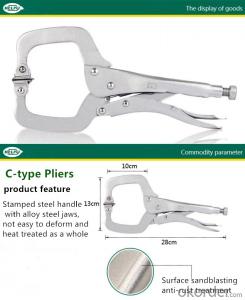

Pictures of pictures:

Order guide:

General Order Information

We take great pride in our work and in the wide variety of products that we offer.

We are experienced in servicing the US market, European market and Asia market .Please be aware that our production lead times depend on specific items and item quantities.

Our success has been based on our professinal for hand tools market.

Check below for more information on placing an order

- Q: Oil box wrench type

- Sata three claw, chain, belt (GM, for most of the oil filter)! A casing (one bushing, one size)!

- Q: What is the difference between worm gear and worm wheel?

- Difference1) the worm gear is equal to the gear; the worm is equal to the rack.2) the worm is an active part; the worm wheel is the follower.3) many worm gear has an interesting feature that other gear sets do not have: the worm can easily turn the gear, but the gear does not rotate the worm. This is because the screw angle is very shallow, when the gear try rotation screw, the screw will let keep friction between the gear and the screw in situ.

- Q: How to change the type of adjustable spanner?

- The utility model is also called a live wrench, and is a tool for screwing or loosening an angle screw or nut. Electrician commonly used 200, 250, three 300mm, the use should be based on the size of the nut matching.

- Q: M42, what is the outer diameter of the six point nut socket wrench for the side s=65?

- Socket wrench: it consists of a plurality of sockets with six corners or twelve corners and is provided with various attachments, such as a handle, a connecting rod, etc., and is especially suitable for screwing bolts or nuts with very small or very deep twist positions.

- Q: What is the torque wrench? What's it for? How do you use it?

- Bending type torque wrench. When the bolt is locked, when the preset torque value is reached, the wrench will bend at the front end to indicate the value of the torque reached."Self torque torque wrench", when the preset torque value is reached, the front will automatically slip, no longer force, never twist.

- Q: What's the torque of the 1/2 ratchet wrench?

- Usually, the 1/4,3/8,1/2 refers to the length of the square interface on the wrench, 1/4 stands for the square head, the dimension is 6.3MM, 3/8 stands for 9.5MM, and 1/2 stands for 12.5MM. Mainly depends on the torque value to choose the wrench.1/4 boats pull, especially suitable for small size 14MM elastic nut sleeve.3/8 "in the" pull ", suitable for matching within 24MM sleeve.1/2 "big torque wrench, relatively large, suitable for collocation within 32MM working sleeve.

- Q: What's the difference between an electric wrench 28V and an 32V?

- Because the current lithium wrench on the market are 18V, the full power of the highest voltage of 21V, 32V is a virtual standard, 28V is also a virtual target. The actual battery pack contains 10 18650 electric cores, a single 18650 of the core is 3.6V, a row of 5 series to get 18V voltage, and then the two lines in parallel, to get the capacity of the battery pack. You can use a multimeter to measure the amount of electricity, when the amount of electricity is 18V, full of electricity when the maximum voltage is 21V.

- Q: What specifications of inner six angle wrenches are required for installing mountain bikes?

- Under normal circumstances, the horizontal is the place where the number 5 sitting bar, there is basically a kettle No. 7-8, some are 4, there are also 5 front fork of the lock ring, where some are used No.1

- Q: Why are the plum blossom wrench to bend

- The rotation angle of the plum spanner is limited, such as 10 bolts are distributed at the same time on the plane, and the other 9 bolts are likely to be distributed inside the rotation radius of the wrench, which blocks the wrench to remove the bolt. So the two wrench generally bent, out there for people operating space.

- Q: What wrench does the bicycle need to remove the screws from the rear axle?

- New (most bikes are now 15MM) are 15 with a 15 socket or a plum wrench. The rear axle of the bike is not M8, and it is all M10.

Send your message to us

High quality 12.5mm quick-release ratchet

- Loading Port:

- Ningbo

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords